In recent years, with the popularization of the domestic production of high power and ultra-elevated fiber lasers, laser cutting machines in my country have shown rapid development. Their cutting capacity has passed to be able to cut thin plates of only a few mm. Like auxiliary gas for laser cut, oxygen, nitrogen and compressed air are generally included.

In the article “Selection and application of air compressors in laser cutting machines using compressed air as auxiliary gas”, the author of this article discussed in detail that the use of the Compressed air as auxiliary gas for metal cutting is a common economic and practical treatment method for laser for cutting machines. Due to the significant economy of the use of compressed air as auxiliary gas for laser cut, manufacturers of laser cutting machines that do not actively push the air cutting have now started to actively introduce their machines Laser cut when promoting laser cutting machines. (Figure 1) and (Figure 2) are the advantages of using the compressed air cut when promoting the super-high power cutting machine of two laser cutting machines.

The laser cutting economy using compressed air as auxiliary gas is obvious. At the same time, because the integrated air compressor is easy to install, covers a small area and is easy to move, laser cutting machines that use the air cut are generally equipped with dedicated dedicated air compressors to the laser cut. However, if the elimination of water and wastewater flow from the integrated air compressor system are incorrect and in a timely manner, it will have a big impact on cutting quality and cutting efficiency, and In serious cases, it can even cause high economic losses.

Why do you say it?

To answer this question, let us first examine the amount of liquid humidity generated when compressing the air 1m3 / min at a pressure 16 bar (this pressure is the compressed air pressure in most machines Laser cutting currently using the air cut)? Thermodynamics, we know that the humidity content in the air is:

Or,

P – Air pressure, KPA;

PS – partial water vapor pressure, KPA;

PSB – partial pressure of saturated water vapor, KPA;

ϕ— – Relative humidity of air,%

The most common season when compressing the air is summer, the most common wet and hot time temperature is about 35 ℃ and relative humidity is around 80%. It is 0.0297 kg / kg (dry air).

When compressed at a pressure of 16 bar, if the exhaust temperature is 80 ° C, the humidity content in the compressed air is 0.0178 kg / kg (dry air).

This means that 0.0297-0.0178 = 0.0119kg / kg (dry air) of liquid water will rush. Assuming that the exhaust volume of the compressor is 1 m3 / min and operates for 10 hours a day, the liquid water precipitated during the day will be:

0.0119 * 60 * 10 * 1.29 = 9.21kg

Most of these precipitated liquid waters will be mixed in the lubricant, causing the emulsification and deterioration of the lubricant and will deteriorate quickly, and will bubble a lot when the lubricant in the oil and gas separator works (see Figure 3). If the foam accumulates a lot and the oil and gas separation filter element is surrounded by foam, the oil and gas separation filter element will lose its interception and filtration function on the Lubricant, and a large amount of lubricant will pass through the oil and gas separation filter element and enter the compressor’s exhaust pipeline, which will allow the filtration and purification of the compressed air from behind becomes extremely difficult.

According to calculations, under the admission conditions of 35 ℃ and 80% relative humidity, it is necessary to ensure that exhaust exhaust gas at 16bar has no liquid water precipitated and that the exhaust temperature must be greater than 92 ℃, which, which must be opened via a temperature control valve. For users with a much larger air compressor capacity, it is necessary to force the lower limit frequency of the functioning of the air compressor to prevent the increase in temperature.

Second, even if the exhaust temperature of the compressor is well adjusted so that no liquid water precipitates lubricating oil, the cooling process will cause a large amount of liquid water to condense in the tank gas storage and gas water separator. From (Figure 4), we can see that after the compressor is executed for several hours, a lot of liquid water can be released from the gas storage tank.

Let’s continue with the example above. and the tracking cooler. Since compressed air speed drops strongly when entering the gas storage tank and the gas storage tank has a large contact area with ambient air, compressed air and air Ambient will generate more convection heat exchange, which will further reduce the temperature of compressed air temperature and produce a more stable and stable air.

Generally, the temperature of the compressed air passing through cooling after cooling is approximately 12 ~ 15 ℃ higher than the room temperature. Therefore, at an ambient temperature of 35 ° C, the temperature of the compressed air in the gas tank will not exceed 35 + 15-5 = 45 ° C. At 16 bars, the humidity of the saturated air at 45 ° C is 0.0035 kg / kg (dry air), which means that there will be 0.0297-0.0035 = 0.0262 kg / kg (dry air) of the water accumulation liquid in tank gas. Assuming that the exhaust volume of the compressor is 1 m3 / min and operates for 10 hours a day, the condensate accumulated in the gas storage tank will be:

0.0262 * 60 * 10 * 1.29 = 20.28 kg

The volume of the integrated air compressor is around 300L ~ 400L, and 20.28 kg of condensate are generated every day. If this is the case, the compressed air will envelop a large amount of liquid water in post-treatment equipment such as the precision filter after the cold dryer, which means that post-treatment equipment cannot Manage at all, whether it is water or residual oil, because the filtering element is wet with water.

Because, according to the principle of work of the precision filter, it can only filter particle dust, micro-oil and water mist. Quickly saturated, which puts air molecules through the filtering element. The result is the result that everyone wants to see. In order not to work, especially for the extra-road power cutting machine, which can burn costly optical lenses in serious cases.

Therefore, for an integrated air compressor, it is necessary to tell the operator that in order to ensure the normal operation of the laser cutting machine, it is necessary to develop the good habit of manually unloading the condensate in the Gas storage tank before and after and after stop every day. Even if the gas tank has an installed automatic sewer valve, it is necessary to carry out such operations every day, because the automatic sewer valve can be dirty and blocked.

Before the compressed air leaves the gas storage tank and enters the dryer, the gas temperature will be further reduced by the convection heat exchange between the pipeline and the ambient air. When the 5 ℃ falls at 40 ℃. According to the above calculation formula, the humidity content of the air saturated at 45 ° C is 0.0035 kg / kg (dry air), and the humidity content of the saturated air at 40 ° C is From 0.0027 kg / kg (dry air), so before entering the bottom dryer, there will be 0.0035-0.0027 = 0.0008 kg / kg (dry air) of condensation water. Assuming that the compressor’s exhaust volume is 1 m3 / min and operates for 10 hours a day, the condensation water generated by the pipeline before entering the cold dryer at the end of the day will be:

0.0008 * 60 * 10 * 1.29 = 0.6192kg

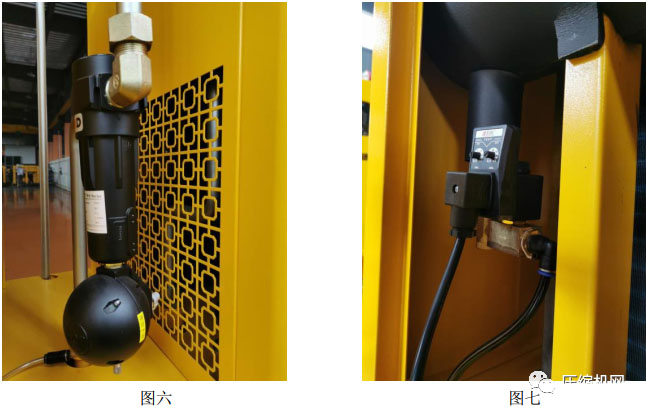

This is why an aerial water separator is installed before the compressed air enters the cooler. The lower part of this aerial water separator is equipped with unloading automatic floating ball water (see Figure 6). There is also a manual output of wastewater under the unloading of wastewater automatically. , this means that the automatic wastewater discharge has a defect.

The integrated air compressor for laser cut is integrated into a refrigeration dryer. The temperature will be reduced to 2. -5 ℃, the condensate water generated by the compressed air passing through the dry dryer). Assuming that the exhaust volume of the compressor is 1 m3 / min and operates for 10 hours a day, the condensate generated when entering the dryer at the end of the day will be:

0.0024 * 60 * 10 * 1.29 = 1.858 kg

If so many condensates are not unloaded properly over time, the precision filter behind will also lose its filter function. Therefore, a water separator is integrated and an electronic waste water valve is installed under the water separator (see Figure 7). In order to unload the condensate over time, the time of discharge intervals of the electronic wastewater valve should not be set for too long.

The compressed air is reduced to 2 to 5 ° C through a cold dryer, and the condensed water generated is discharged over time, then the temperature is back to around 20 degrees, then the extremely small amount of water and The oil mist is filtered thanks to a group of precision filters. , the elimination effect of liquid oil reaches 0.001 ppm, which means that the effect of eliminating oil vapor reaches 0.003 ppm, and it is also very difficult to form the fog of oil on the protective lens.

It should be mentioned that for laser cutting machines, the manual mouth valve under each precision filter must be kept slightly open (see Figure 8), so that the precision filter can be captured at any time (rinse water Or the oil in time without bringing it in the gas supply pipeline of the laser cutting machine. , to ensure that any captured and intercepted liquid substance can be washed from the system at any time and secondly, to maintain the pressure of the gas supply stable system. Wastewater, the power pressure drops approximately 1 bar.

To summarize

The elimination of integrated air compressors and wastewater using the laser cut is in no way a trivial question. If the elimination of water and the discharge of wastewater is not well done, in the smallest direction, this will affect the quality and efficiency of the laser cut; Whether it is a designer or a maintenance worker, you should have a correct understanding of the importance of eliminating water and unloading the water from an integrated air compressor with A laser cut in practice, you can make sure that the integrated air compressor is properly and timely.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.