By starting, by leveling and polishing the tool, it can improve the quality of the tool and prolong its lifespan. After the end of the tool, the name of the process before the coating is not unified at home and abroad.

2

Why the passivation of the tool

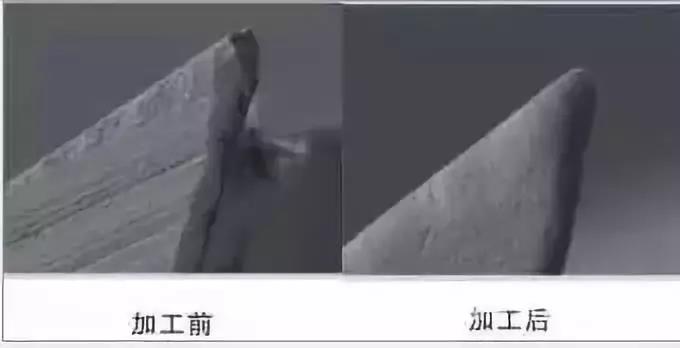

There are microscopic notches (i.e. tiny cracks and saws) from different degrees of a sharpening of the tool after ordinary grinding wheels or diamond grinding wheels. During the cutting process, the micro-enclosure on the edge of the tool is very easy to develop, which accelerates the wear and the damage of the tools.

Modern cutting and automation machines have highlighted higher requirements for the performance and stability of the tools.

3

Passivation of the tool

The purpose of passivation technology of the edges is to resolve the defects of the microscopic space on the edge of the tool after sharpening, so that its on -board value can be reduced or eliminated, reaching the goal of sweetness, of sweetness and sustainability. The main effects of the tool passivation are:

Rounded from the edges: Remove the on -board lands and obtain a precise and coherent rounding treatment.

The blades cause the wear of the tools and the surface of the transformed part will become rough.

Uniformly ponder the grooves of the tool to improve the quality of the surface and the cutting performance.

The more smooth the surface of the groove, the better the suppression of the chip and the higher speed of speed can be made. At the same time, after improving the quality of the surface, the risk of biting the death of the tools and the materials treated is also reduced. It can reduce the cutting force by 40%, which makes the cutter cut.

4

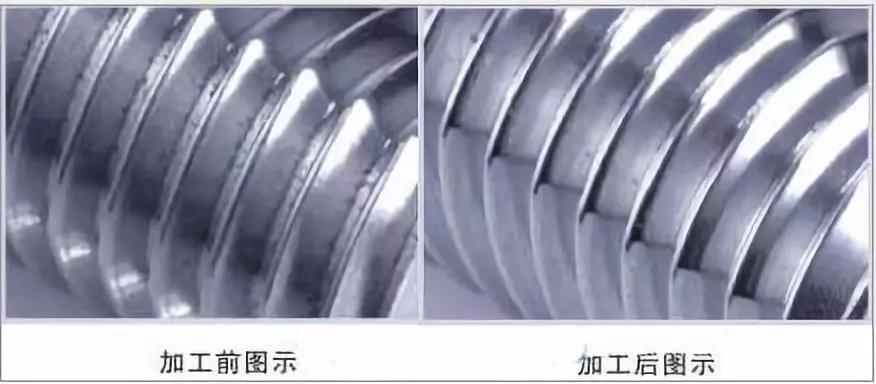

Polling of layers

Remove the protruding droplets generated after the tool coating, improve the surface finish and increase the adsorption of lubrication oil. The surface of the tool after the coating will produce tiny projection droplets, which will increase the roughness of the surface and make the tool subject to generate greater friction during the cutting process and will reduce the cutting speed. After passivation and polishing, the droplets are eliminated, leaving many small holes, which can adsorb more cutting fluid during treatment, which considerably reduces the heat generated during the cut and considerably improves cutting speed.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.