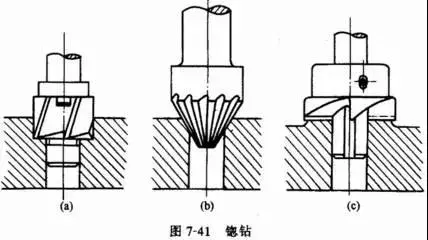

In the event that the deep treatment of the tilted surface holes is necessary, the surface of the seat is generally treated first by a square mill of two edges, then the treatment of the holes is carried out by a drill. The square end -to -headed mill has a concave center on the front side, so that the lower surface after the front treatment is carried out by the square ended mill, then the forest is tilted when the hole is treated through the Forest bit. In addition, when processing counterpins, the surface of the processing bottom must be flat.

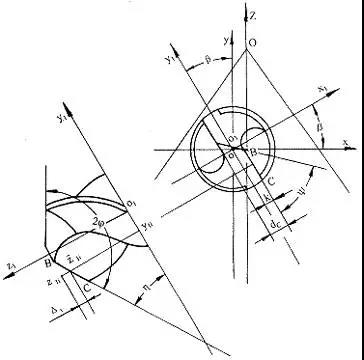

The drilling bit for the offset, the upper angle of the drill bit for the counter is 170 to 190 °, the thickness of the drill of the forest is 0.20 to 0.40 times the diameter of the forest, And the intermediate depression of the cutting edge is 0.01 is 0.01 in the diameter of the drilling bit. In addition, in the forest, it forms in a form that the opening angle of the groove provided in the rotation direction is greater than 90 ° compared to the cutting edge.

Another type of drill, the opening angle (groove width) of the drilling bit compared to the groove provided in the direction of rotation of the cut edge is 75 to 85 °, the intermediate depression on the side of the Pointe is 0.03 to 0.07 times the diameter of the forest and the edge of the tail root is the intermediate depression on the east side from 0.35 to 0.70 times the diameter of the forest. In addition, by adjusting the opening angle of the groove to 75 to 85 °, the chips are reduced and curly, and the release of the fleas is improved.

The problem is:

In these drilling bits, the opening angle of the groove is wide, so the chips are not easily blocked, but there are chips which open constantly and accumulated in the grooves. Treatment of the rough surface where chips bite in the edge.

In addition, the opening angle of the groove is narrow, so the chips are easily attached with the surface of the wall of the groove and curved. Groove.

Drilling bits used for treatment of holes and guide meters

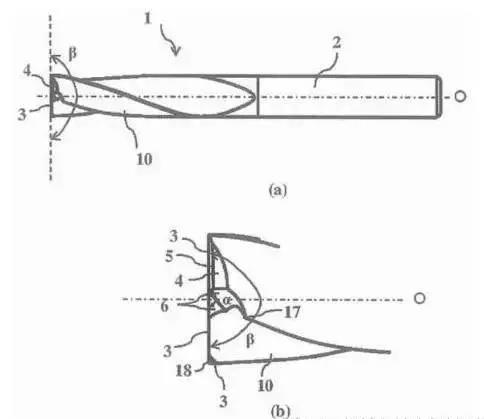

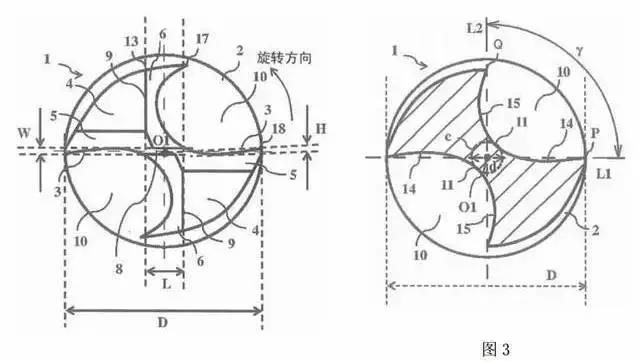

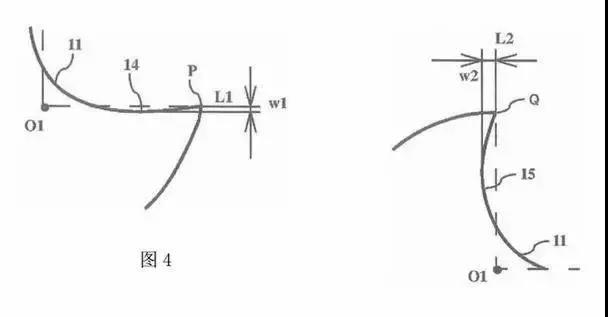

Forest 1 of Figures 1 to 5 is a solid forest, and at least the part which includes the cut edge 3 is made up of hard materials such as the Super-Duv alloy the axis of the rotation center o of the drilling bit 1. The body of the generally cylindrical drilling bit 2 in diameter D.

Depending on the figures. From each slice 3 the discharge groove of chip 10 arranged in the direction of rotation of the drilling bit 1 and the edge of the tail root 4 arranged in the opposite side of the 3 cutting edge so as to be in contact with the discharge groove of the chip 10

In addition, the cut edge 3 is arranged near Center O1 from Forest 1 at the external peripheral end of the circle with the diameter D, and is continuous with the lateral surface of the body of the drilling bit 2. In other words, the Body of the drilling bit 2 Includes two edges of cut 3, two grooves of chip 10, two edges of tail root 4 and two first cuts (end gass) 6. In addition, the terminal on the edge of the edge 13 on the edge of the edge 13 tail 4 on the opposite side of the cut edge 3 is connected to the discharge groove of chip 10 and is supplied to a position opposite at the edge of cut 3.

In the front view of fig. 1, at the front end of the drill 1, the terminal of the tail edge 13 on the edge of the tail 4 in front of the cut edge 3 is oriented towards the rear (the back side of the forest 1) in the opposite direction of rotation of the rotation of the rotation of the rotation of the rotation of the first point of cutting end 17, at the front end of forest 1, of the terminal of the edge of the tail 13 on the edge of the tail 4 on the side Opposed on the edge of cut 3, with the opposite direction of the rotation of the first point of cutting end 17. In other words, in the opposite direction of the rotation direction, the cut edge 3 – the rear tool surface Front 5 rear – The edge of the tail root 4 – The first cut 6 – The discharge groove of the chip 10 is arranged in sequence. The first opening 6 reduces the contact resistance of the axis of the rotation center o of the front end of forest 1 and its neighborhood, that is to say the central part.

Practical effects

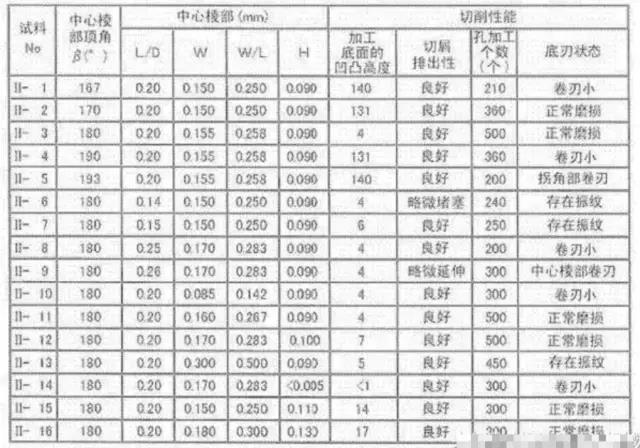

The body of the drilling bit is covered with figures of the figs. It should be noted that the diameter of the drill bit is 3 mm, the thickness of the nucleus is 0.45 mm, the upper angle α of the drilling bit is 180 °, the opening angle γ of The discharge groove of the chip when it is seen from the front end is 89 degrees and A / D is 0.4. In addition, the forest performance was evaluated by the following cutting conditions. The results are presented in the table.

(Cutting conditions) Equipment to be cut: S45C treatment diameter: 3 mm treatment speed: 75 m / min Speed: 8000 rpm Feed: 0.065 mm / rotation cutting depth: 4.5 mm cutting form: Treatment of molding cutting environment: elements of evaluation of the wet cut: shape of the surface of the treatment base, unloading of the chip when the number of holes is 250, the number of holes which can be treated and the ‘Forest of the forest at the time of the end of treatment

As the table shows, in any sample, the shape of the lower treatment surface is flat or concave and concave is less than 150 μm, the discharge and the chip of the chip are good and there are many treatments holes. In particular, in sample n ° II – 2—4, 7, 8, 10-16, which has an L / D of 0.15 to 0.25, and an angle of apex on the central edge of 170 at 190 °, the unloading and the drill of the chip a little in good condition, no roller pale is produced in the central edge, and there are a lot of holes.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.