Threads are mainly divided into connection threads and transmission threads

For the connection of the threads, the main treatment methods are as follows: tapping, wire sewing, car wire, roller wire, wire friction, etc.

For transmission threads, the main processing methods are as follows: end and grinding, crabbing grinding —– Coarse end, etc.

Here are various treatment methods:

1. Cut on wire

Generally refers to the method of treatment of threads on parts using training tools or abrasive tools, including mainly turn, milling, tapping, drying to agitation, grinding , grinding and cutting cyclone. When you turn, grinding grinding and grinding threads, whenever the part turns, the machine-tool transmission chain guarantees that the rotation tool, the grinding tool or the grinding wheel moves a guide With precision and evenly along the axial direction of the room. When tapping or threading, the tool (press or plate teeth) moves with respect to the part, and the wire groove formed first guides the tool (or part) to move axially.

The spinning spinning tower can be made using a forming filming tool or a threaded comb knife (see thread treatment tools). Threads turning with filming tools are a common method for monobloc production and in a small group of threaded parts. SCALE production. The precision of ordinary towers can generally only reach 8 to 9 levels (JB2886-81, the same below);

2. Filling

Mill with a disc or a mill to comb on a wire mill. Disk -shaped strawberries are mainly used to die from trapezoidal external threads on parts such as screws and worms. Strawberries in the shape of a comb are used to die of ordinary threads and conical wires inside and outside. Because they are crushed with strawberries on multiple edges, the length of their work part is greater than the length of the wire which is treated, so that the room only of the room must be turned from 1.25 to 1.5 tower before treatment. The accuracy of the thread grinding height can generally reach levels from 8 to 9, and surface roughness is R 5 to 0.63 microns. This method is suitable for mass production of threaded parts of general precision or rough treatment before grinding.

3. Thread

It is mainly used to treat the precision wires of the hardened parts on the wire grinders. Depending on the transversal shape different from the grinding wheel, there are two types: the unique grinding wheel and the grinding of multiple wheels. The precision of PAS which can be obtained by wheel grinding with a single line is 5 to 6 levels, and surface roughness is 1.25 to 0.08 microns, which makes the grinding wheel more practical. This method is suitable for precision screws, thread gauges, worms, small lots of threaded parts and clarification plates of shovel. The grinding of multi-line wheels is divided into two types: longitudinal grinding method and cutting grinding method. The width of the grinding wheel of the longitudinal grinding method is smaller than the length of the grinding wire. The width of the grinding wheel of the cutting method is greater than the length of the wire. But the precision is slightly lower, so the grinding wheel is more complicated. The cutting grinding method is suitable for the taps with larger lots and the grinding of wires for fixing.

4. Groan of the wire

Type -type thread tower tools or screw type with softer materials such as cast iron, and turn forward and reversal to improve the precision of the height. The hardened internal wires are generally used to eliminate deformation and improve precision by grinding.

5. Tapping and threading

The tapping consists in using a certain torque distance to screw the tap in the background hole pre-drilled on the part to treat the inner wire. The thread consists in cutting the external wire on the part of the rod (or the pipe) with plate teeth. The accuracy of tapping or threading depends on the accuracy of the tap or plate teeth. Although there are many methods for treating internal and external threads, small diameter internal threads can only be treated by taps. The tapping and metal seams can be used manually or towers, drilling machines, tapping machines and wire sewing machines.

Principles to select the use of the Cup of the Wire Truck

Since the height of the wire (or lead) of the wire is specified by the drawing, the key to select the quantity of cut when filming the wire is to determine the N -pin speed and the AP cutting depth.

1) Selection of pin speed

According to the mechanism of the spindle rotating 1 rotation when filming the threads and that the tool feeds 1 guide, the power speed when filming the threads in the CNC round is determined by the selected spit. The thread guide (the thread step is the wire when a head wire is used), which is equivalent to the power speed VF VF = NF (1)

As equation 1 shows, the VF power speed is proportional to the quantity of power f. Therefore, when you choose a pin speed during the turn of a thread, you must consider setting the power system parameters and the electrical configuration of the tooltip to avoid the occurrence of “blurred teeth” of the thread or not near the start / end the point does not meet the requirements.

In addition, it should be noted that once the thread begins, the speed value of the spindle cannot be modified and the pin speed, including the finish, must be selected in the first power treatment. Otherwise, the CNC system will make the “jamming” of the wire due to the quantity “exceeding” of the reference pulse signal of the pulse coder.

2) Choose cutting depth

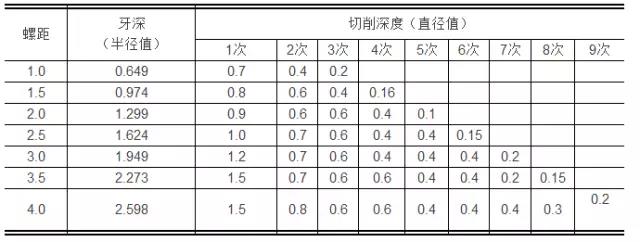

Since the turn of the wire is the filming of the molding, the resistance to the tool is bad, the quantity of cutting power is large and the cutting force is also large, it is therefore generally necessary to feed the Tool several times and to select a relatively reasonable cutting depth depending on the decrease. Table 1 lists the supply times and the benchmark for cutting depth for the cutting of common metric threads for readers.

Table 1 Power time and cutting depth of the common metric thread cutting

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.