Thanks to the research and production of trials of rings of interior tooth -tooth -to -end, measures have been taken from the entire forging, treatment and thermal treatment process, precision and Stability of the toothed part is improved and the product success rate is improved.

The outside diameter of the parts of the internal gear cycle for the extraction projects illustrated in Figure 1 is 570 mm, the maximum inner diameter is 509 mm and the thickness of the wall is 30 mm. Its wall thickness is 1/20 in the outside diameter and belongs to parts with thin walls. The room material is 35crmo, the heat treatment method is to temper + nitrative, and dental hardness should be ≥ 500 hp, the depth is ≥ 0.5 mm, which is difficult to treat and severe deformation of treatment thermal.

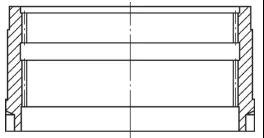

Figure 1 Structure of the internal ring part

Party test production includes forging whites, machining, special tool design, heat treatment and production and transport, etc. After multiple reductions in stress of treatment and heat treatment stress, the parts have reached good precision and good stability, and at the same time, they are considerably improved.

Treatment technology

Given the characteristics of the easily distorted parts, the main process of determining the processing of the internal ring are: Forging → Standardization → Coarse → Detection of defects → Quality packaging → Semi-finition → Roaring insertion → Old-up to low temperature → Because precision → France of combination → Fine insertion tooth → Fit

Empty forging

The white forging process is: cut → heating → overwhelming → flattening → punching → ring ring → normalization. The manufacture of whites adopts the upheaval and punching method of steel ingots to improve metal density, refine coarse grains and obtain a uniform wall thickness. The standardization treatment appropriately after forging can obtain a smaller thermal constraint in white and improve cutting performance. At the same time, the rings grinding process increases the rate of use of materials by around 12%, which reduces production costs.

Raw truck, detection of injuries

The rough grinding process cuts most of the treatment surface treatment allowance, ensuring that the outer circle and the interior holes are 8 mm, the unilateral allowance of the end of the end is 4 mm and that the surface roughness value reaches RA = 6.3 μm, prepare for subsequent detection of defects. Thanks to the defect detection process, the internal quality of the parts is inspected.

Quality packaging

By dipping as a preparatory heat treatment process, the distortion of the nitrade is reduced, so that the parts can not only obtain strong resistance, but also obtain excellent tenacity, plasticity and cutting performance.

The process used for the caliber is: heating at 850 ℃ × 1.5h → Oil extinction → Tempery at 600 ℃ × 1.5h → Oven cooling → Air cooling.

During temperature and temperature, you must pay attention to the entire lifting process as mounted on paper, and use the cutting heating, and the transfer time of extinction is controlled within 30 years. air cooling. The hardness hardness can be obtained by dipping 217 ~ 250HBW.

Semi-fine, thick teeth insert

The underside of the semi-finishing process is straightened and tightened up, turning the outer circle, the hole in the inner hole and the top of the tooth with free tolerance at the size of the design, leaving an external circle of 2 mm and ensuring that the roughness of the roughness of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface surface roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the roughness of the surface of the outer circle of the teeth reaches ra = 3.2 μm, because the reference to correct the teeth insertion process;

In the thick teeth insertion process, the upper side is oriented upwards and the upper circle of the car’s teeth is corrected and tight. And the normal public line has a margin of about 1 mm.

Thermal aging

High temperature aging is made by slowly and evenly heating the ambient temperature at 550 ℃ for the receipt of stresses, keeping heat for 6 hours, then strictly controlling the cooling speed for less than 150 ℃ (the temperature difference In the oven is necessary to be less than ± 25 ℃ and the heating rate is ≤50 ℃ / h, the cooling speed is ≤ 20 ℃ / h to avoid secondary stress).

This process removes early constraint, eliminates the internal constraint of the part, stabilizes structure and size and improves mechanical properties.

Precision car, tooth insertion

The precision filming process finds 8 points of the TOP circle of the tooth symmetrically, with a tolerance of 180 ° steering ≤0.04 mm and a tolerance of 90 ° direction ≤ 0.08 mm. Between the light and the room, and the size of each part of the vehicle with drawing requirements. The surface roughness value of a section of the upper stop -to -stop turning point RA = 3.2 μm, which is used as a reference for the correction of the teeth insertion process. Turn the parts according to the same process to turn to the drawing requirements.

In the teeth insertion process, the top of the top of the end is oriented upwards and the correction belt is corrected by the vehicle, and the dental insertion knife at level A is used to insert the teeth. Among them, the margin after the first insertion is 0.2 mm from the common normal line, and the cutting speed is 16 times / min; Drawing requirements, to avoid the cone of the tooth part, walk a circle when the quantity of radial power supply is 0 mm / z.

Nitrative

The nitrade process is: cleaning → oven → heating → insulation → heating → insulation → cooling → air cooling.

Clean before nitride. The nitride furnace is made of paper and must be placed gently without inclination and suspended in the air. The second-stage gas nitratide treatment is used, and the 200 ℃ oxidation pre-oxidation and 300 ℃ is carried out, then 520 ℃ × 15h is used, and the ammonia decomposition rate is around 25% ; 560 ℃ × 12h, and the ammonia decomposition rate is 50% on the left and right; Meets the nitrade depth requirement ≥ 0.5 mm. After inspection and analysis of the test block, the infiltration layer and the hardness meet the technical requirements, and the deformation of the part is ≤0.02 mm.

Conclusion

The material of the internal ring is the common 35CRMO nitrido steel. Since the structure of the parts is slim wall, the requirements of production technology are high. Distortion of parts is a systematic project, and the connection between empty preliminary manufacturing, heat treatment, processing and manufacturing, production and transport and heat treatment and the heat treatment processes directly affect the final result. The processing process uses a unified reference to reduce treatment stress. The nitrade treatment of the annular gear ensures nitratide deformation by reasonable loading methods, an increase in air and temperature pressure. Thanks to a strict control of the multiple processes, the parts manufactured in the test finally reach the deformation of the diameter of the part ≤ 0.02 mm, a radial circular jump ≤0.02 mm and the level of teeth of the teeth 7, responding fully with the drawing and use requirements.

Expert comments

In response to the difficulties of processing annular gears with thin walls, during the trial production process, measures were taken of whites, mechanical treatment, special tools and thermal processing process to reduce stress of Deformation and improve the accuracy and stability of the teeth of the parts of the parts.

The highest point of the article is the integrity of the process. The content of the process is concise and concise, without any extrapolation. Precision and tooth insertion processes are consistent and the heat treatment process is reasonable.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.