1. Damage of tool 1.

1) The rush edge has slightly collapsed

When the structure of the material, the hardness and the room of the room are unequal, the front angle is too large, the point resistance is too low, the process system is not rigid enough to cause vibrations or A cut interrupted and that the quality of grinding is not good, the cutting edge is subject to a slightly collapse. After that, the tool will lose part of its cutting capacity, but it can continue to work. During the continuous cut, the damaged part of the on -board area can develop rapidly, resulting in greater damage.

2) Pointe or cut peak breaks

This type of damage is often generated in more severe cutting conditions than causing a minor of the point, or it is developed. The size and the crushing beach are larger than those of the micro-cluck, which means that the tool completely loses its cutting capacity and must finish its work. The situation where the tip of the knife collapses is often called peak loss.

3) Break the blade or the tool

When the cutting conditions are extremely severe, the quantity of cut is too large, there is an impact charge, there is a microcasse in the blade or the tool material, and there is a residual constraint in the blade And inappropriate functioning, the blade or the tool can be caused by the residual constraint in the blade due to welding and sharpness. Once these damage is, the tool cannot continue to be used, which led to bottling.

4) The surface of the blade is derogated from

For materials with strong fragility, such as cemented carbides, ceramics, PCBN with a high content of ICT, there are residual constraints on the surface due to defects or potential cracks in the surface structure, or in reason for welding and weakening. To occur when the surface of the tool is not sufficiently stable or the surface of the tool is subject to alternating contact constraint. The coat can occur on the surface of the front knife and the knife can occur on the surface of the rear knife. The possibility of coating tools is high. Once the blade is slightly off, it can still work, and after a severe peel, it will lose its cutting capacity.

5) Plastic deformation of the cutting parts

Due to the small resistance and the low hardness of the steel and steel at high speed, a plastic deformation can occur in their cutting rooms. When the cemented carbide operates directly in states of high temperature stress and three -way, the plastic flow of the surface layer will also occur, and even the plastic deformation surfaces on the cutting edge or the cutting tip will collapse . The collapse generally occurs when the cutting volume is large and the hard materials are treated. The elastic module of ticked cemented carbide is smaller than that of WC -based cemented carbide, so that the first accelerated its plastic deformation resistance or fails quickly. PCD and PCBN do not mainly undergo plastic deformation.

6) Thermal crack of the blade

When the tool is subjected to an alternating mechanical load and a thermal load, the surface of the cutting part will inevitably generate an alternative thermal constraint due to repeated thermal expansion and contraction, which will cause fatigue and the Crackon of the blade. For example, when the cemented carbide strawberries make high speed grinding, cutting teeth are constantly subject to a periodic impact and alternating thermal stress, and comb cracks are generated on the front cut surface. Although some tools do not have obvious alternating loads and alternating constraints, the thermal constraint will also occur due to incoherent temperatures of the surface and the interior layers. The rear blade of the crack formation can continue to operate for a period of time.

2. Tool wear and tear

1. Depending on the reasons for wear, it can be divided into:

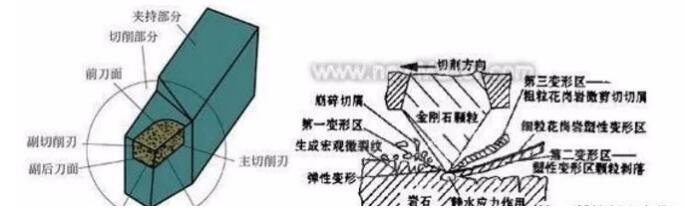

1) Abrasive wear and tear

There are often tiny particles with an extremely high hardness in the material to be treated, which can mark grooves on the surface of the tool, which is an abrasive frosting. Abrasive wear and tear is present on all sides, and the surface of the front knife is the most obvious. In addition, the wear of the sesame can occur at different cutting speeds, but for the low speed cut, due to the low cutting temperature, the wear caused by other reasons is not obvious, so The wear and tear of the abrasive is the main reason. The lower the hardness of the tool, the greater the abrasive damage.

2) Cold welding wear

During the cut, there is a lot of pressure and strong friction between the room, the cut and the surfaces of the front and rear tools, so cold welding will occur. Due to the relative movement between the pairs of friction, the cold welding will cause a break and will be removed on one side, causing the welding wear to the cold. Cold welding wear is generally more serious at medium cutting speeds. According to experiences, fragile metals have a stronger cold welding resistance than plastic metals; The elements are smaller. Cold welding is more serious when cutting steel at high speed and cemented carbide at low speed.

3) Diffusion wear

During the high temperature cut and the contact between the part and the tool, the chemical elements of the two parts diffuse each other in the solid state, modifying the structure of the components of the tool, which makes the surface of the Fragile tool and aggravating the wear of the tool. The diffusion phenomenon always maintains objects with great depth gradients diffusing continuously into objects with gradients at shallow depth. For example, when the cemented carbide is 800 ℃, the cobalt spreads quickly on tokens and parts, and WC will decompose in tungsten and carbon to spread in steel; Steel and iron materials, the cutting temperature is more than 800 ℃ during the steel and iron cut. The surface will be graphicized. The diffusion of cobalt and tungsten is relatively serious, while titanium, tantalum and niobium have strong resistance to diffusion. Therefore, the YT carbide has better resistance to wear. When cutting ceramic and PCBN, diffusion wear is not significant when the temperature is as high as 1000 ℃ -1300 ℃. Due to the same material as the part, the chips and the tools, a thermoelectric potential will be generated in the contact zone during the cut. This diffusion wear under the action of thermoelectric potential is called “thermoelectric wear”.

4) Oxidation wear

When the temperature increases, the surface of the tool oxidizes to produce softer oxides and rubs against chips. For example, at 700 ℃ ~ 800 ℃, oxygen in the air undergoes an oxidation reaction with cobalt, carbide, titanium carbide, etc. in cemented carbide, forming softer oxides;

2. Depending on the form of wear, it can be divided into:

1) The front knife surface damage

When cutting plastic materials at a high speed, the room of the surface of the forefoot near the cutting force will be added in a concave form of the crescent under the action of the shavings, so it is also called croissant wear. At the start of wear, the cutting angle increases, which improves cutting conditions and is conducive to curling and rupture of chips. Capping and damage at the tip. The wear of the croissant is generally not caused when cutting brittle materials or when cutting plastic materials at lower cutting speeds and thinner cutting thicknesses.

2) cutting edge of the blade

The wear of the tip of the knife is wear on the surface of the rear blade of the arc of the tip of the knife and the surface of the adjacent secondary back blade, which is a continuation of the wear on the tool . Due to poor conditions of heat dissipation here and the constraint is concentrated, the wear speed is faster than the surface of the rear blade. called Groove Wear. They are mainly caused by the hardened layer and the cutting texture of the transformed surface. When cutting materials that are difficult to run with a strong tendency to harden, it is very likely to cause grooves. The wear of the tip of the tool has the greatest impact on surface roughness and the machining precision of the part.

3) Wear of the Sillon blade

When cutting plastic materials with a large cutting thickness, the basket bottom of the tool may not be in contact with the part due to the presence of accumulated shavings. In addition, the surface of the rear blade generally comes into contact with the part, and a wear belt with a rear angle of 0 is formed on the surface of the rear blade. Generally, in the middle of the working length of the cutting edge, the surface of the basket bottom is relatively uniform, so that the degree of wear of the surface of the rear plane can be measured by the width of the wear strip of the surface of the back plane VB of the cut of the section of this section.

Since different types of tools almost always carry the surface of the rear plane in different cutting conditions, especially when cutting brittle materials or plastic materials with a smaller cutting thickness, the wear of the tool is mainly the wear and tear of the surface of the rear plane and the wear belt The measurement of the VB width is relatively simple, so VB is generally used to indicate the level of wear of the tool. The greater the VB, it will increase not only the cutting force and will cause cutting vibrations, but will also affect wear on the arc of the tool, thus affecting the processing of processing and the quality of surface treatment.

3. How to prevent tool damage

1) Depending on the characteristics of materials and parts to be treated, reasonably select various types and grades of tool materials. On the premise of having a certain degree of hardness and resistance to wear, the material of the tool must be ensured to have the necessary tenacity;

2) Reasonably select the geometric parameters of the tool. By adjusting the front and rear angles, the main and secondary angles, the angles of tilt of the edges, etc.;

Make sure good strength of the tip of the tip and the tool. The grinding of negative chamfers on the rush edge is an effective measure to prevent the cracking of the knife;

3) Ensure the quality of the welding and sharpening and avoid various defects caused by poor welding and sharpening. The tool used in key processes must be crushed to improve the quality of the surface and check the cracks;

4) Choose the amount of cut reasonably to avoid excessive cutting force and excessive cutting temperature to avoid damage caused by tools;

5) Ensure that the process system has good rigidity and reduce vibrations as much as possible;

6) Take the correct operating methods and try to prevent the tool from carrying or withstanding a less mutational load.

3. Causes and countermeasures of tool breaking

1) The grade of the blade and the specifications are not selected correctly, as the thickness of the blade is too thin or the grade is too hard and too brittle when it is roughly treated.

Breakage: Increase the thickness of the blade or install the blade vertically, and choose a brand with a high resistance and tenacity with high flexion.

2) The geometric parameters of the tool are not properly selected (as the front and rear angles are too large, etc.).

Counter-measure: You can start rethinking the tool from the following aspects. ① Reduce the front and rear corners correctly. ② Use a wide angle of negative edge tilt. ③ Reduce the main deviation angle. ④ Use larger negative leaflets or on -board arcs. ⑤ Growing the transition cutting edge to strengthen the cutting point.

3) The blade welding process is incorrect, resulting in excessive welding stress or welding cracks.

Remains: ① Avoid using a three-sided closed blade groove structure. ② Correctly select the weld. ③ Avoid using oxygen-alcyne heating and insulation heating should be maintained after welding to remove internal stress. ④ Use mechanical clamping structures as much as possible

4) The incorrect hanging method will cause grinding and grinding cracks; The swing of the vibrations of the cutting teeth after the PCBN grinder striker is too large, which will cause a load of the cutting of the cut, which will also cause drilling.

Countermeasures: ① Use intermittent grinding or diamond grinding grinding. ② Choose a softer grinding wheel and cut it frequently to maintain the sharp crushing wheel. ③ Pay attention to the quality of sharpening and strictly control the oscillation of the cutter cutter teeth.

5) The use of the cut is unreasonable. is too small; When cutting high manganese steel when a material with a strong tendency to work in hardened, the quantity of food is too small.

Counter-measuring: Realize the cutting dose.

6) Structural reasons such as the unequal lower surface of the groove of the mechanical tightening tool or the blade exceeding for too long.

Breakdown: ① Cut the lower surface of the tool groove. ② reasonably arrange the position of the cutting fluid nozzle. ③ Add coated carbide seals under the blade by hardening the knife rod.

7) The tool is worn excessively.

Conversely: Change the tool or replace the cutting edge over time.

8) The cutting of cutting fluid is insufficient or the filling method is incorrect, which means that the blade is suddenly heated and cracked.

Countermeasures: ① Increase the flow of the liquid cut. ② reasonably arrange the position of the cutting fluid nozzle. ③ Use effective cooling methods such as spraying cooling to improve the cooling effect. ④ Use * Cut to reduce the impact on the blade.

9) The installation of the tool is incorrect, such as: the cutting tool is installed too high or too low;

Conversely: reinstall the tool.

10) The process system is too rigid, causing too large a cut vibration.

Breakdown: ① Increase the auxiliary support for the room to improve the tightening rigidity of the room. ② Reduce the length of the overhang of the tool. ③ Appropriately reduce the rear corner of the tool. ④ Use other vibration elimination measures.

11) inadvertent operation, such as: when the tool is cut in the middle of the room, it moves too hard; Before the tool is removed, stop the car.

Countermeasures: pay attention to the operating method.

4. Tumors of custard

1) Cause of training

In the nearby part of the point edge, in the contact zone of the knife chip, due to the high support force, the basic metal of the chip is integrated into the microscopic unequal peaks and valleys on the surface of The front blade, forming a real metallic contact without gap, resulting in a bond phenomenon, this part of the contact zone of the knife chip is called the link area.

In the link area, a thin layer of metal material will accumulate and remain on the surface of the front blade in the lower layer of the chip. As the chips flow continuously, under the push of a subsequent cutting flow, this layer of stagnant material slips compared to the upper layer of the chip and becomes the base of the tumor of accumulation of chip. Subsequently, a second layer of stagnant cutting material will be formed on it, so that a continuous accumulation of strata will form a stagnant tumor.

2) Characteristics and impact on cutting treatment

① The hardness is 1.5 ~ 2.0 times higher than the room material, and it can replace the surface of the forefoot for the cut. -The space contact zone when the accumulated fleas fall.

② After the formation of the tumor of the accumulation of chip, the front angle of the functional tool is considerably increased, which plays a positive role in reducing the deformation of the chips and the reduction of the cutting force .

③ Since the accumulation of shavings exceeds outside the point edge, the actual cutting depth is increased, affecting the dimensional precision of the room.

④ Cutting accumulation will cause a “groove” to the surface of the room, affecting the surface roughness of the room. ⑤ The fragments of the accumulated chips will be binded or will be integrated into the surface of the room to cause hard particles, affecting the quality of the treated surface of the room.

According to the above analysis, we can see that the accumulation of dispersion tumors is not conducive to cutting treatment, in particular for the finish.

3) Control measures

The following measurements can be taken to prevent the basic material from the chip from binding or deformation and strengthening the surface of the front blade.

① Reduce the roughness of the surface of the front knife.

② Increase the front angle of the tool.

③ Reduce the cutting thickness.

④ Use a low -speed cut or a high speed cut to avoid cutting speeds subject to suffocation formation.

⑤ Perform appropriate heat treatment on the room material to increase its hardness and reduce plasticity.

⑥ Use cutting fluids with good anti-adherent properties (such as extreme cutting fluids containing sulfur and chlorine)

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.