This article presents a kind of upper and bottom of the structure of the landing frame. The surface sums up a set of easy-to-operate controlled process parameters and the product quality treatment method.

1 preface

The material produced by our company is made of ultra-high-fortune steel, and hardness is ≥53hrc. HAS. This structure is the first innovative design of the domestic landing frame.[1,2]。

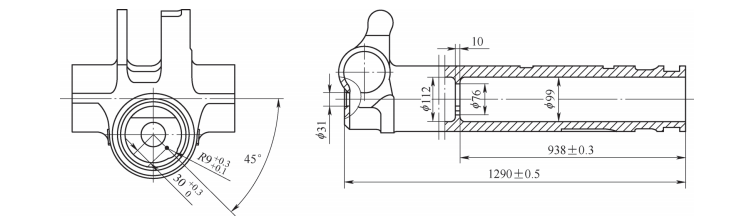

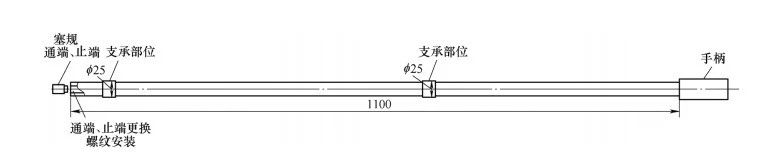

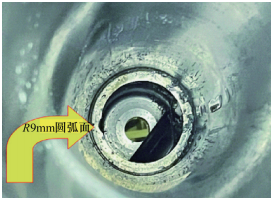

Figure 1 R9 mm Surface structure of the arc

2 Products analysis

Analysis of the product structure, the surface of the R9mm arc is located in the deep pores of the product and the surface of the Eccentric R9mm arc.

1) The exclusion of the surface of the Eccentric R9mm arc is located on the left side of the room. Entering the right hole knife. The treatment of the input treatment on the right side, due to the surface of the arc of the treatment site, the long -term diameter ratio is greater than 10, which is a long length ratio that the treatment in deep holes. Guarantees the quality of the product[3]。

2) The surface of the R9mm Eccentric arc is unable to observe treatment parts during treatment.

3) In the product processing process, the size of the surface of the R9mm arc is not effective to detect.

3 Process analysis

In response to the curved surface structure of the inner hole, traditional treatment technology generally uses treatment methods such as crushing of the angle, grinding deep holes and internal sexual intercourse. In this article, the surface of the R9mm arc is due to the eccentric structure which makes the ratio long diameter of the tool> 10, and the angle of crushing of the head and grinding deep holes cannot be accomplished. Can be used to support knife tools in interior pores. However, the treatment site for this product is an eccentric arc surface. The basic verification test process is: the clinger line determines the angle position on the surface of the R9mm arc surface → Install test parts on the CNC Lathe card → Level the test parts by the diagram via the rule high. Standard tools on the knife rod → Use the knife → Use the CNC program to perform the treatment. Several times adjust the process parameters and processing procedures. The rate can reach 40%. During the test, the “axial pioneer” product was caused by a knife composition, which has a large impact on the life of the anti-vibration knife and CNC towers. Therefore, this plan has no operation for the processing of products and must seek new treatment ideas.

a) Use the Tour CNC B) Install non-standard tools on the anti-vibration knife post

Figure 2 CNC tour treatment test

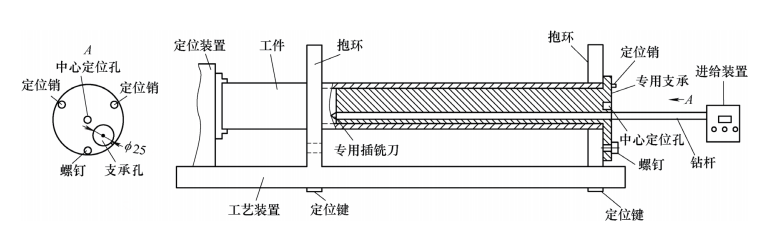

4 Tightening scheme design

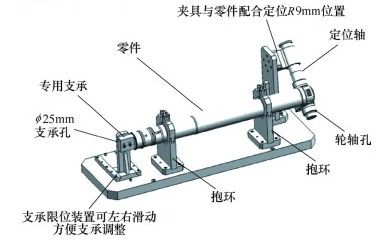

In order to resolve the processing problems mentioned above, after analysis and research, a special processing process system has been designed for products of structure and processing of products (see Figure 3). This device provides bed power or a CNC horizontal tool. Figure 5) implement the treatment of the R9mm arc, special inspection (see Figure 6) to obtain the surface detection of the R9mm arc, and use this device to carry out an insertion treatment and an arc surface shredder R9mm biased in the ultra-long deep hole.

Figure 3 Special processing process device

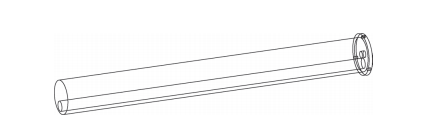

Figure 4 Special support

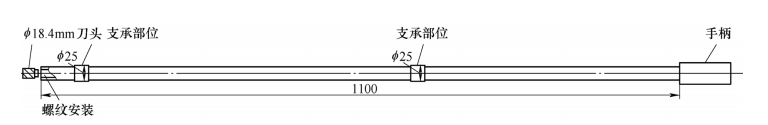

FIG

Figure 6 Special inspection tool

5 Implementation of the plan

Innovate with the processing process method, design and manufacture new process equipment and use special tools and inspections to complete the processing and detection of the product.

(1) The fibrotation positioning product is installed on the process device via the lighting device.

Figure 7 The product is installed on the process device

1) Install the lighting device via the positioning keys to the label of the bed on the bed or a CNC horizontal machine to complete the positioning of the luminaire.

2) Install the piston rod on the process device, adjust the positioning device to locate the piston rod and tighten the piston rod by tightening the ring to complete the positioning of the product on the luminaire.

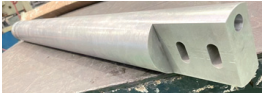

3) Install the dedicated support (see Figure 8) in the piston rod φ99 mm the internal hole and tighten it through the screw and the lighting device.

4) Find the position of the positive hole φ25 mm in the center of the device to locate the main axis.

(2) The specific implementation plan for the implementation of the surface treatment of the R9mm arc is as follows[4]。

1) Install the special tool on the main axis and the starting bed of the knife machine to determine the depth position of the tool to be processed.

2) Thanks to the dedicated support of the pores φ25 mm, the special mouth and the millingr, rotate the pin, control the power settings and implement the treatment of the surface of the R9mm arc.

3) Once the treatment is completed, the tool comes out of dedicated management and cleans dandruff.

(3) The specific implementation plan for the surface treatment of the R9mm arc is used as follows.

1) Use a special inspection tool manually, test the size of the surface of the R9mm arc with φ 25 mm hole wall and determine the post-standard size interval of product treatment via the Separate regulations (φ18.2 mm) and the end of stop (φ18.6 mm).

2) When the segregation is not available, the stages of the treatment of the surface of the R9MM arc continue until the end of it.

Figure 8 Physical object of dedicated support

6 implementation effect

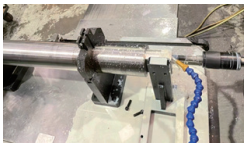

1) Use the bed to provide motivation, use a dedicated lighting device to install clip and positioning products. is simple. The product processing site is illustrated in Figure 9.

Figure 9 Product processing site

2) The treated arc surface treated is illustrated in Figure 10. This process method converts the eccentric curved surface to the surface of the non-effect, and the treatment of the rotation of the knife also realizes insertion insertion and grinding. quality.

Figure 10 The surface of the R9mm arc after treatment

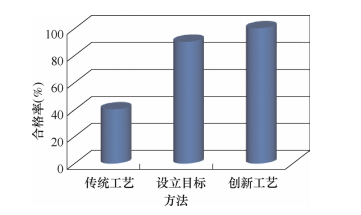

3) The qualification rate of traditional crafts and the innovation process is illustrated in Figure 11. The qualification rate of the innovative process is> 97%. which cannot be guaranteed.

Figure 11 Comparison of the qualification rate

7 final words

The process plan described in this article compensates for the processing space in the treatment of the surface of deep holes with high length of length on the surface of the arc on the attachment of the aircraft, resolving The use of the crushing of the angle, the grinding of the deep holes, and the internal hole relationships. The design of the Institute design has tended to adopt such structures, which have a lot of prospects for application and promotion value.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.