Ion beam machining technology is atomic level processing means. For a long time, the basic technology of ion beam treatment has been monopolized by the United States, Great Britain, Germany and other countries.

Bundle Ion’s equipment was once a product blocked by Western countries. . Liu Jinsheng was appointed by Qian Xue as the head of the R&D team of the Pusher Ion Beam, who threw the development system for ion sources theory in China. The ions spraying machine has managed to break the technical blocking of Western countries in this technological area.

After that, due to certain special needs and requirements, the department has always served military domains such as national aerospace, weapons and the supply of technical equipment and support for major national tasks, including infrared detectors Satellite multi-track digitization, soldiers, soldiers of multi-track resolution, soldiers, soldiers, multi-tracks. Infrared imaging systems, gyroscope gyroscope precision inertia guide, fiber fiber and satellite crystal gyroscope system for special ion beam systems. The Department also provides equipment to a large number of national institutions such as the Chinese Academy of Sciences, Aerospace Sciences and Technology, China Science and Technology, Tsinghua University and L ‘University of Shanghai Jiaotong.

With the growing demand for ion beam equipment on the civilian market, Liu Jinsheng founded Beijing Edvans and produces ion beam equipment in the civil field.

The flexible basic coating is a key technology for the manufacture of flexible portable equipment. Abroad offers a technical guarantee for the manufacture of the new generation of electronic products in China.

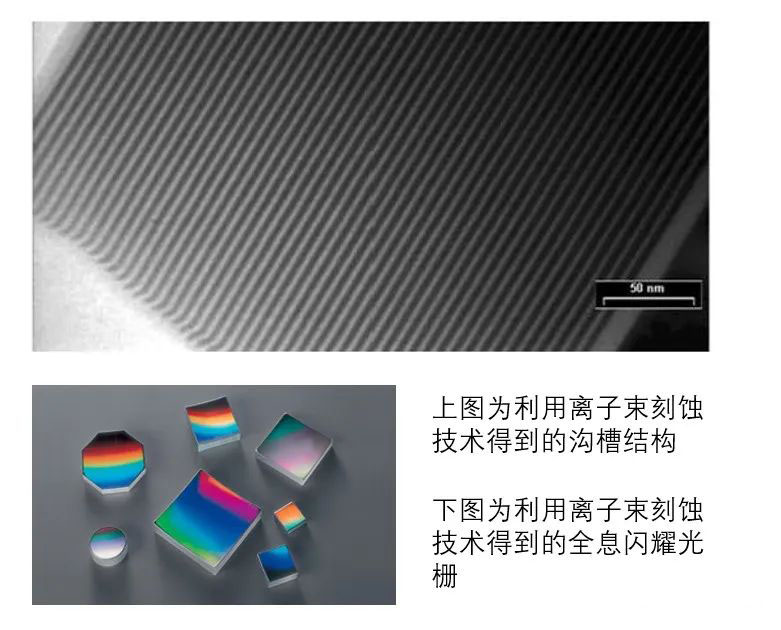

Currently, giants such as Bosch, Texas Instruments and semiconductor semiconductor have focused on the development and application of non-Silicon micro-electrical system fleas. The engraving machines cannot most of the raw materials can be carved, such as metal materials, alloys, metal oxides, carbides, polymers, semiconductor materials, ceramic, conductors and isolates, etc. ., which can be used for graphic sculpture of small graphics.

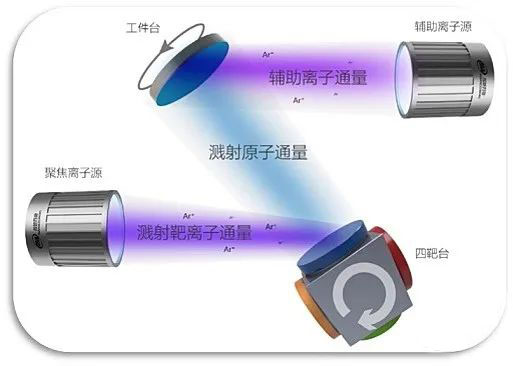

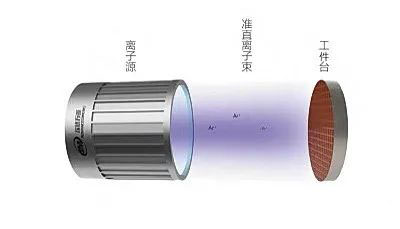

The engraving of the beam of ions consists in filling the inert gas in the discharge chamber of the ion source and making it ionize to form a plasma, then the grille is drawn and accelerated by the grid on the surface of the surface surface solid. of engraving.

Today, the treatment capacity of the EDWANS ions engraving machine is at the forefront of the world, but the price is less than half of foreign products.

Currently, Edwans has developed the fourth generation ion beam engraving system, the CAIBE system, the bipolar beam manufacturing system, the three -ion beam synthetic film system and the system fast engraving of the first international microcomputer.

In addition to the production of ion beam machining equipment, Edwans has also developed various manufacturing processes, including alloy alloy pressure sensors, cinema resistance, an inductance of the film, a thin superconductive film , an aluminum nitride film, etc.

The thin pressure sensor in thin alloy can be used for aerospace, high pressure co-rail technology, control of industrial automation, transport of oil and gas, etc.; The film can be used for quantum communication; The aluminum nitride film can be used for piezoelectric and dielectric components, high frequency high speed communication, etc. This is the basic material of the next generation of wireless communication technologies. Prepare aluminum nitride films. Edwes used bivileys to bomb aluminum atoms in a beam.

In terms of optical devices, Edwans has developed the first large -sized optical device of China for Changchun optical machines and provided it with equipment and process software.

Conclusion

CHIP is an essential key component of smart equipment and high equipment, and Ion bundle treatment technology is the basic technology of the future manufacturing of fleas.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.