The tool-tool, known as the Mother Industrial Machine, is one of the most important tools for industrial production.

The machine tool industry is production equipment for the equipment manufacturing industry.

By taking the CNC Liaison technology with the highest five axes as an example, the CNC connection machine for five axes is the only way to resolve the processing of key industrial products such as the wheel of the aerodynamic engine , the leaf plate, the blade and the propeller ship. From the “Badong list” passed to the current “Valianson Agreement”, Western developed countries have always taken the CNC system in five axes and liaison machines in five axes as strategic materials to implement a system of export license. . In recent years, with the rapid rise in the complete national force of China and the reconstruction of the value of the global industrial chain, competition between China and the Western developed countries has beyond the category of commercial protectionism, and has gradually evolved into a new series of technologies and competition from industry. In this context, the aviation of my country, aerospace, weapons, ships, nuclear and electronics, etc., require a complete blockage of Western countries which require treatment of machine-to-link to liaison to Five axes.

The development of the machine tool industry in my country has twists and turns.

1. The stage of high -speed growth (2000-2011) – high -speed growth, large but not strong

High growth

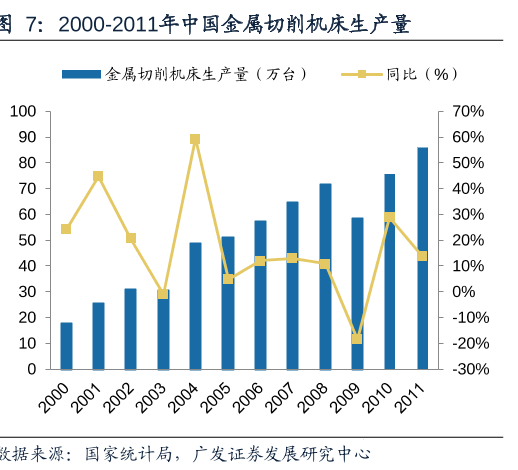

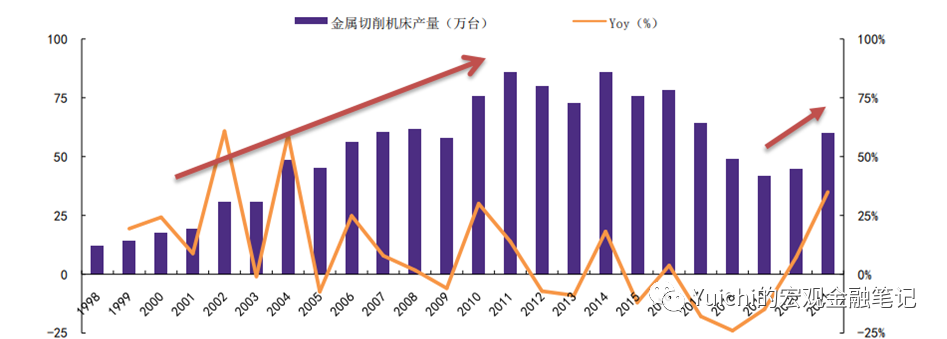

In 2001, China joined the World Trade Organization, the economy entered the scene. In 2000, the production of Chinese metal cutting machines was 180,000 units, an increase of 860,000 units in 2011, an increase of 4 times in 11 years and a composed growth rate composed of more than 15%.

In 2002, the consumption of Chinese machine tools became the world’s leading market and the largest consumption market for machine tools in the world.

In 2009, the production of Chinese machine tools became the world’s leading place.

After that, the production and sales of Chinese machine tools have always maintained the first world.

Jack of Machine Tool Industry-Shenyang Machine Tool

Shenyang Machine Tool was the representative of the Chinese machine industry at that time. Heath, Germany.

In 2011, Shenyang Machine Tool ranked first in the world machine tool industry for 18 billion yuan sales. But such scenes have become a flames flame.

At the same time, as a high -speed development, large but not strong is also the characteristic of this step.

My country’s airport industry is mainly low -end machines. In addition, foreign countries have also made a technical blockade in China. According to the Valianson agreement, the export of machine tools and machine tools above the agreed country is prohibited to export to China.

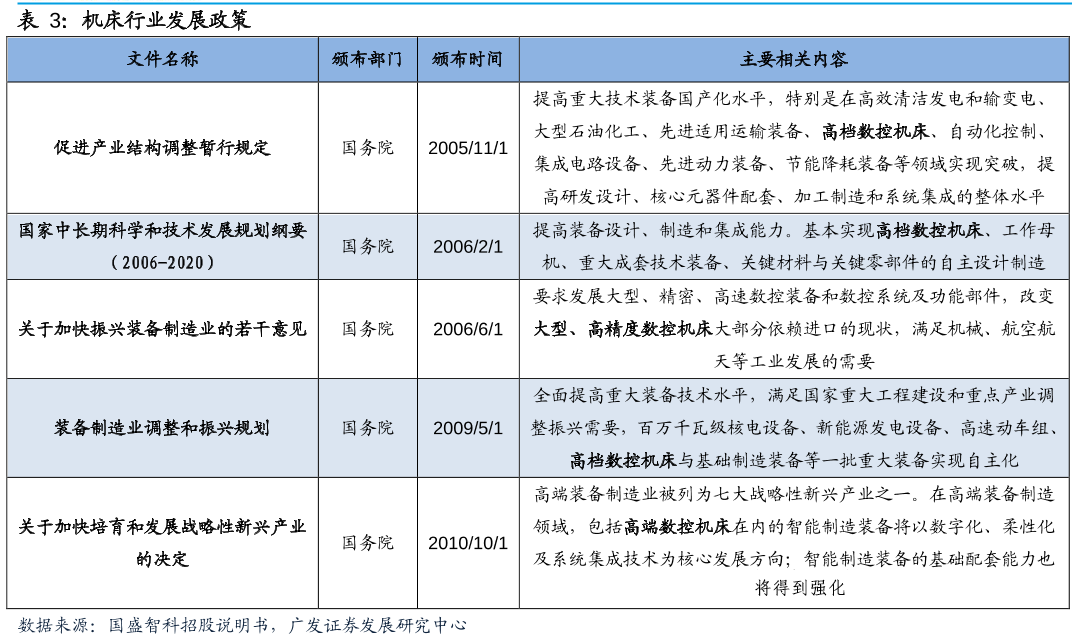

In order to improve the technical level of the machine tool industry, the State has introduced a series of policies and has formulated the objective of the machine tool industry towards high development. In 2006, national and long-term contours of scientific and technological development planning (2006-2020) published by the Council of State proposed that by 2020, it is necessary for independent design technology of high-end CNC machine tools.

In order to reach large and strong, companies have embarked on the path of mergers and acquisitions

The machine tool industry is an industry that requires long-term accumulation. Some of the companies with a foreign head are all stores of the century. High field?

Overcoming the curve is a beautiful vision, and sometimes it is also a poison.

In the context of the rapid development of national machine tools, in order to reach the development of departures, national companies have chosen to use mergers and acquisitions as shortcuts.

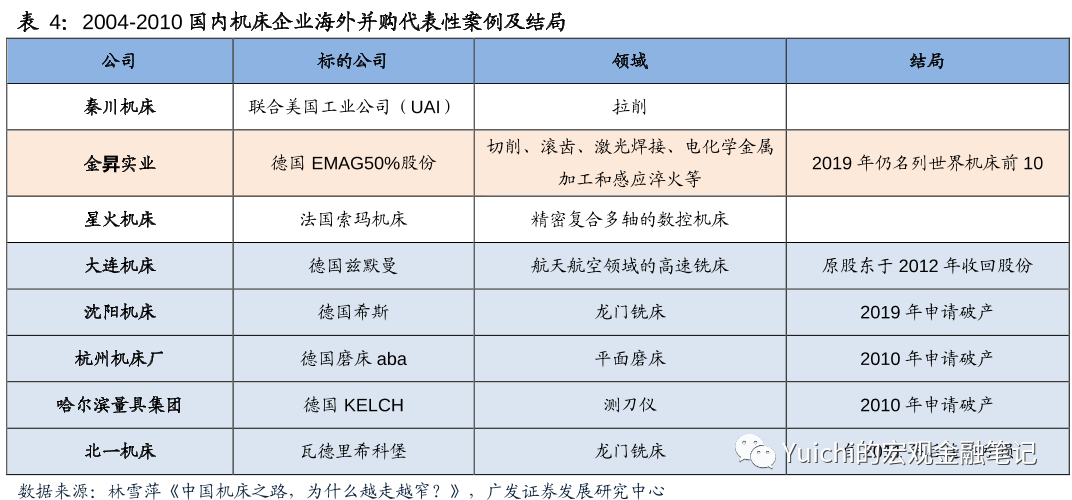

From 2004 to 2010, a large number of national airport companies merged and acquired foreign companies, but most of them ended with a failure.

The high-end escape route at Shenyang airports and acquisitions, the self-research, all end in check

In 2004, Shenyang Machine Tool Mergers and Acquisitions in German Machine Tool Corporation, Hiriz, Masterring CNC Machine Tool Technology. However, German law stipulates that local intellectual property rights must not be moved and it is prohibited to transport advanced technical representatives of industry at the time, the machine tools superior to the five to the China. It turns out that the acquisition has not only brought the company’s substantial improvement to the company this time, but has become the burden of the company. In 2012, the Germany of Germany EIS was on the verge of bankruptcy, and Shenyang Machine Tool had a blood transfusion of 20 million euros (around 160 million yuan) – the 105 million yuan in net profit from net profit Annual of the Shenyang machine in tools in the Shenyang machine in 105 2011. At that time, more than 10 billion yuan.

The acquisition has not resolved the technical problem and has only been able to take independent research and development. At that time, the domestic CNC machines necessary to import CNC systems in Japan and Germany.

The i5 project has been developed for 5 years and Shenyang sub-tool machines have burned more than a billion yuan. In 2015, the I5 machine-tool was listed, but it was not born. On the one hand, from 2012, the global machine tool industry entered a downward cycle and, on the other hand, customers have a low acceptance of new products. Therefore, sales of new products are difficult.

In order to quickly capture the market, the i5 CNC machine-tool is iterated every few months. In addition, Shenyang Machine Tool adopts the “bicycle sharing” model, rented to customers by deposit and burns money to fight for the market over time and treatment of treatment. In 2018, there were 18,000 machine tools equipped with the i5 system, establishing a recording. But profitable, the money was burned and the debt crisis of Shenyang Machine Tool exploded. In 2018, the debt was 20.2 billion yuan, the debt ratio was 99% and in 2019, it lost 5 billion yuan.

2. Downstream industry phase (2011-2019)

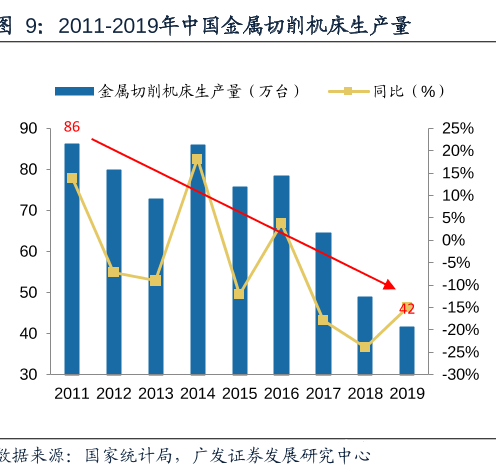

In 2011, the production and sales of the Chinese machine tool industry entered its peak. However, since then, the manufacturing development scheme has changed and the manufacturing industry in mid-term has started to transfer to Southeast Asia. , the demand for the machine tool industry was affected and the industry continued to shrink. In 2019, the production of metal cutting machines in the machine tool industry fell to 420,000 units, a decrease of more than 50% against 860,000 units in 2011.

Machine-tool sales telephone: 15910974236

From the point of view of the industrial structure, the Chinese machine tool industry has entered a weak trap. Small and medium-tools are fiercely competitive in the field of low-end machine tools, forming two clustering zones, the capital of Tengzhou, Shandong, the capital of the economic machine tool of Zhejiang Yuhuan-China. On the other hand, in the high breakthrough process, large companies cannot generate profits after having invested in huge research and development in capital. And development, the more difficult it is to operate.

In the past, the four celestial kings of the Chinese machine tool industry (Shenji, Kunji, Dalian, Qinchuan), Shenyang Machine Tool, Dalian Machine Tool have gone bankrupt and reorganized, Qinchuan Machine Tools has become a St Qinchuan. At that time, the “eighteenth Luohan” machine-tool also left Jinan’s second machine tools.

In the latest ranking of the world airport industry, Yamazaki Mazaki, Japan first ranked with a turnover of US $ 5.2 billion.

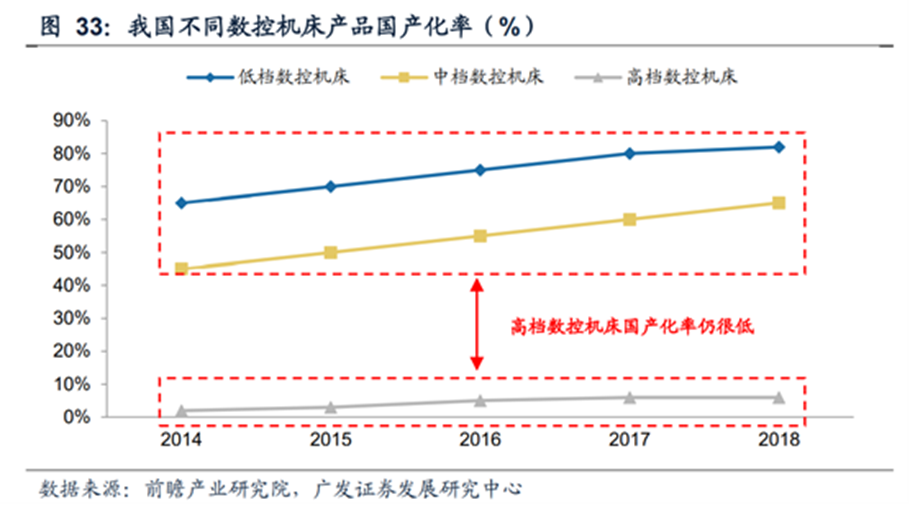

From the point of view of the technical level, according to the “pailaulages and prospects for the development of the 2019 CNC machine tools” published by the industry research potential, the location rate of CNC machine tools at low End in my country in 2018 was 82%, which underwent a location;

From the point of view of profitability, in 2019, there were 15.1% losses in machine tools designated by Chinese, 29.3% of losses in 2020. Period last year.

Look at the default reasons for Shenyang Machine Tool-Summary

Looking at the Shenyang Machine Tool, thanks to bankruptcy and reorganization, the Shenyang machines have maintained the operations, but now they are in crisis. In 2021, the income from the Shenyang machine-tool was 1.7 billion yuan, with a loss of 863 million yuan and a net asset of 498 million yuan. Over the past 10 years, its loss has a total of 12.8 billion yuan.

Summate the reasons for the failure of the development of the Shenyang machine:

1. The business model and the development strategy did not correspond to competition in the industry.

Based on market evolution technology, mergers and acquisitions, etc., this type of technology cannot be purchased, and even if it is purchased, after 5 to 10 years of absorption, digestion And out of the market, it will immediately be delayed.

This is the right way to follow the Route d’Auto-Recherche, but the development of the high airport industry must have a deep understanding of the downstream industries. .

Even if you develop a good product, it is unrealistic to open the market in a short time, because the machine tool is an industrial treatment tool, which determines the precision of the product. The release of new products.

In addition, in terms of cash flow, most machine tools are mainly low-end products. At the same time, companies strive to develop high -end products, and the company’s cash flows will be nervous. Since the research and development of airports are long-term work, if the shortage and the long-term nature of the process are underestimated, serious consequences will occur.

Finally, in terms of personnel, R&D is the foundation of the high machine tool industry, and it is important to maintain the stability of the technical backbone. How to link and motivate staff is an important factor in business management.

3.2019 to date, recovery

From 2019, the machine tool industry entered a recovery period. Increase of 35% of years over one year and an increase of 40 against 420,000 units in 2019 exceeding 40%.

On the other hand, the machine tool industry has a 10-year cycle, because the life of the tool-tool is generally about 10 years. Over the next 5 years.

From the point of view of politics and the environment, in April 2021, foreign media reported that the United States threatened national security by the use by China of high provision machine tools for the manufacture of J -20 and asked that Switzerland was not allowed to export high provision machine tools to China. From the flea to lithographic machines to high precision machines, my country has developed in the field of technological blocking. With the continuous progression of the transformation of manufacturing and upgrading, emerging industries such as new energy, rail transport, aerospace, precision molds and 3D printing increased quickly.

From the technical field, Chinese machine tools have pierced in high fields.

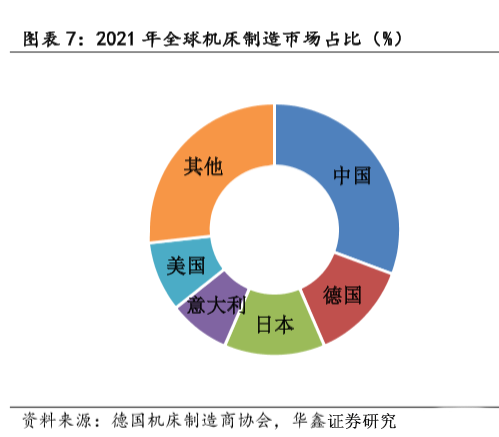

From the point of view of the size of the market, the total value of the production of the global machine industry in 2021 was 70.9 billion euros, including 21.8 billion euros in the production value of my countries, representing 31%, ranking first; Germany and Japan on the world market, respectively. The first five countries occupy 74% of the world, reflecting the high concentration of the global market for machine tool manufacturing, and market opportunities and competition in the future will always be launched in TOP5.

Pending the development of the future machine tool industry:

1. From the point of view of the implementation of the national strategy and the industrial provision, it is necessary to vote

2. The low-end machine-tool enters the peak of replacement, and the side of the offer has undergone 10 years of compensation.

3. The national alternative rate in the field of high machine tools will increase and become an important factor in the supply industry.

4. The industry enters the cycle of prosperity.

5. The advanced company will not increase the level of short -term profit. on a large scale.

6. Focus on: Concept of company team, strategic stability, business management, cash management, team’s technical stability.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.