1. Planning context

Since industrial robots generally have 6 degrees of freedom, it can easily reach X, Y, Z, A, B, C, a rigid six -dimensional movement in the Descartes space, so if the industrial robots are transformed into a machine With CNC tool, it can develop the treatment range for treatment.

The reality is that the precision of the trajectory of industrial robots is not high enough. ). Consequently, there are still many difficulties and painful points to use industrial robots for the treatment of machines.

Pre-procedure treatment such as polishing, polishing and eliminating terrifying in certain precision requirements, as well as the treatment of certain non-metallic materials such as wood, plastic parts, 3D printers, etc. , and use industrial robots to replace machine tool data to complete the processing of machines.

2. German mode

There is a company in Germany called Siemens, Siemens PLC and CNC Systems are well known in the world; After the acquisition of the United States).

The permanent magnet synchronous servomotor adopted by Kuka Robot is a dedicated model provided by Siemens in Germany.

Before the entirely made up of Kuka Robot, regulators of the German government sought to acquire Kuka robots to prevent German technology from being mastered by Chinese technology, but Siemens was not entirely entirely. Robots is easy to do with its technical strength.

In 2015, the author participated in the training of the headquarters of Kuka. Robotics.

3. Solution

(1) Software:

Who.cnc Sinumerik:

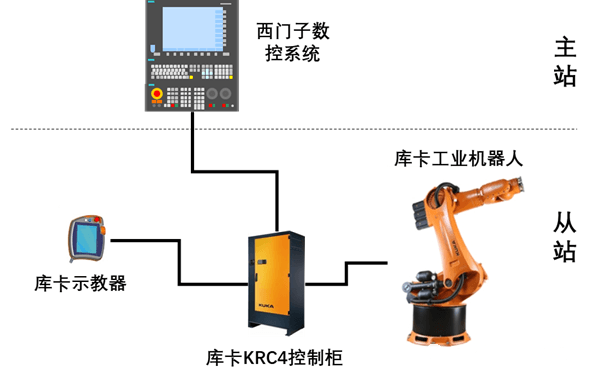

The process software provided by the Kuka robot is used to connect the Siemens 840D SL CNC system and the Kuka KRC4 robot control firm.

Kuka.cnc work principle

As a main station by the CNC system, the robot is the station;

Movement instructions in code G are executed by the robot;

Planning the path is executed in Sinumerik;

Industrial robots are only used as tools for the treatment of machines.

(2) Material:

Siemens 840D sinumerik

As a superior machine controller, he is responsible for the planning and instructions of the paths.

Kuka KRC4 control cabinet:

As a station controller, responsible for the reception and execution of the instructions for the main station.

Siemens and 200S module:

High speed communication version, for the exchange of bus data.

(3) Communication:

Kuka.Profinet / Profiafe’s software package must be installed to support profinet communication (Profisafe).

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.