The characteristics and performance benefits of the aluminum alloy make it one of the favorite materials for the light of the car today. The molding characteristics of aluminum alloy plates and technical applications in the stamping process, the welding process and the coating process in the body application are studied and analyzed for the current state of the application of aluminum aluminum plates in my country. Technical problems that have raised certain solutions and suggestions.

With the development of the modern automotive industry and the increasingly strict requirements of China energy, environmental protection and safety, because the lightness of vehicles can effectively save fuel consumption and Reducing travel, the scope of the application of aluminum alloy plates in the field of automotive manufacturing can be used. Aluminum has the advantages of small density, quality of light, good molding procedure, recycling and use, energy reduction and environmental protection, and Can improve driving performance and safety and car comfort of the car, reduce fuel consumption, reduce emissions and reduce environmental pollution.

Aluminum alloy application on bodywork

Currently, more than 12% to 15% of aluminum consumption worldwide is used in the automotive industry, and some developed countries have exceeded 25%. In 2002, the whole European automotive industry consumed an aluminum alloy of more than 1.5 million T in one year, of which around 250,000 t was used for body manufacturing, 800,000 T was used for the system automotive transmission and 42.80,000 T were used for manufacturing cars to make driving cars of mechanisms and suspension agencies. We can see that the automotive manufacturing industry has become the most important consumer of aluminum materials. The application of the aluminum plaque of punching on the body of the car is illustrated in Figure 1.

Figure 1 The application of the aluminum plate on the bodywork

The requirements of the aluminum alloy stamping plates on the stamping

Aluminum alloy and molding plaque formation requirements

After investigation, the aluminum alloy molding process is consistent with the general cold plate. requirements.

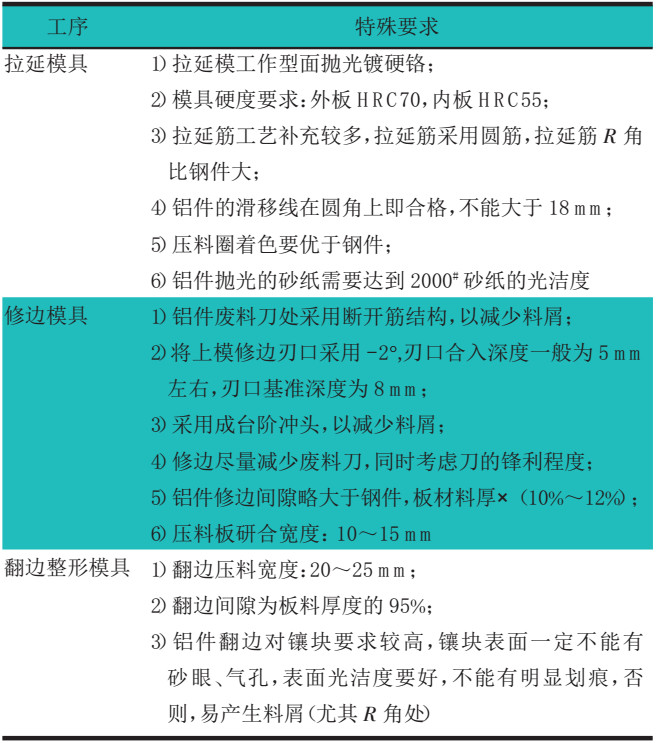

Table 1 Aluminum plate mold requirements

Precautions for long -term custody of aluminum alloy plates

1) Once the aluminum plate does not harden, the intensity of the yield increases.

2) The paralysis oil / anti-class oil used for production is easy to volatilize.

3) The surface is easy to oxidize and it should not be placed outdoors.

The requirements of the aluminum alloy stamping panels on welding

The main processes in the aluminum alloy welding process are resistive welding, CMT cold transition welding, archery welding with tungsten poles, riveting, precipitation and polishing, etc.

Aluminum alloy plate without riveted connection process

The aluminum plate without riveted connection consists in tightening 2 or multi-layer metal plates through the pressure equipment and the special molds, then form an internal connection point encrusted with certain resistance to traction and shear. The thickness of the connection plate can be identical or different, there may be a layer of glue or other intermediate layer, and the material can be identical or different. The connection effect is good and does not require auxiliary connectors.

Aluminum alloy alloy connection process

The aluminum plate is connected.

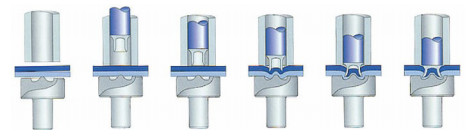

Figure 2 Rivet connection process to drink

The characteristics of the Rivettante connection process

1) Resistance to dynamic anti-temperature fatigue high of the connection point of the locking rivet, the resistance of the impact resistance is greater than or equal to the connection point of the punctual welding;

2) You can visually detect the quality of the connection. The rivets are completely set up in the room and at the same time, a salient contact is formed on the other side of the connection piece, which is considered qualified;

3) Connected materials do not need to drill in advance, the process is simple;

4) The connection point is sealed, which will not enter into gas and liquid, causing corrosion of the material;

5) For metals, non-metals, metals of different materials, different thickness and different forces can be connected.

Resistance welding

Currently, the resistance welding of aluminum alloys generally uses an intermediate frequency or high frequency resistance and welding processes. The connection and the possibility of generating aluminum magnesium dust are very small. Most of the welded smoke and dust are particles of metal surface oxide and surface impurities. During the welding process, it is equipped with a local excretion of the site.

CMT COLD TRANSITION WELDING AND CYCLIÉ ARC WELL

These two welding processes, due to the protection of non -derived gas, at high temperature, contact with fusion metal and oxygen is insufficient. In the working environment, aluminum and magnesium dust is formed, and there is a risk of explosion in aluminum-magnetic dust.

The requirements of the aluminum alloy stamping card process on the side of the roller

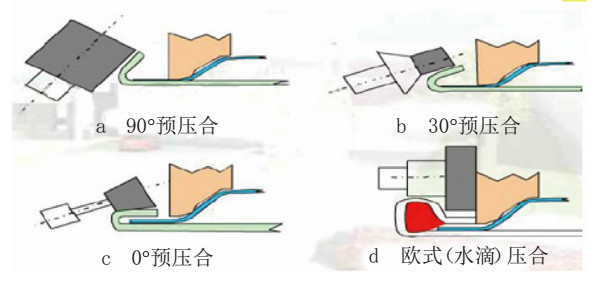

1) The aluminum alloy edges are very different from the binding of the roller pressure to the cold plate. 30 °, and compression in the form of V cannot be carried out;

2) ALUMINUM Alloy Alloy Alloy Pressure Mixing requirements: at 20 ambient temperatures, parts that have just recovered cold storage should not be carried out immediately.

Shape and characteristics of the aluminum alloy stamping board roller

Form edge of the aluminum alloy stamping board roller

1) Ordinary compression is divided into 3 steps for the first premises, secondary pre-contribution and final pressure. Usually it is used in the event that there are no specific resistance requirements and the edge of the external flange is normal;

2) The European style pressure combination, as shown in Figure 3, is divided into the first pressure and secondary pressure of pressure, which is generally used in long pressure connections. All the grooves are paired, such as the front cover and the rear cover. In order to reduce or eliminate surface defects, the European style is also used.

Figure 3 Process for European style pressure border

Characteristics of the aluminum alloy stamping board roller

The lower mold and the inscription of aluminum parts are used to use 800 to 1200 # in glass paper to regularly polish the lower and encrusted mold to ensure that there will be no aluminum dormules on the surface .

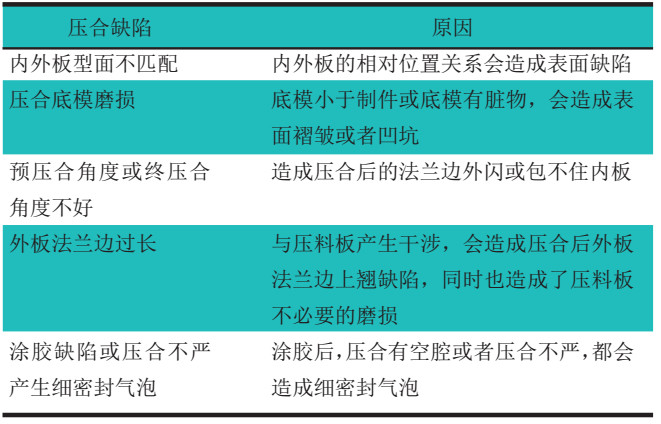

Various reasons caused by aluminum rolls

Various reasons caused by aluminum rolls, as shown in Table 2.

Table 2 different reasons for defects caused by aluminum rolls

The processing requirements of the aluminum alloy stamping card on paint

The principle and function of the aluminum stamping plate washing plate passivation and passivation

Passivation washing refers to the oxidation film and the pollution of the oil which is naturally formed on the surface of the aluminum part, and wrap a dense oxide film on the surface of the room through the Chemical reactions between aluminum alloy and acid solution. After the stamping, the oxide film, the welding of oil colors and glue on the surface of the aluminum parts will have an impact in order to increase the fixing of the glue and the welding, it is necessary to Maintain the connection connection and long -term resistance surface using chemical technology to obtain a better welding essence of the welding, consequently, welding parts such as laser welding and transitional metal welding (CMT) must be washed and passed.

Aluminum Alliam Arque of admissions alley of the lava of the water and detached

Washing and passivation equipment consists of an abandoned area, an industrial water washing area, a passivation zone, a clean water cleaning area, a zone drying and exhaust system. The aluminum parts that must be treated are loaded in the cleaning basket, and after fixing, it is lowered in the sink. All grooves are equipped with pumps and traffic nozzles. The water washing process is: the skin 1 → Skin Skin 2 → Washing 2 → Washing 3 → Passivation → Washing 4 → Washing 5 → Washing 6 → Drying, aluminum flow can omit water washing 2.

Aluminum Alloy Embordement Plate Low and Passivation and Dry Process

1) The room temperature of the ambient temperature at 140 is about 7 min, and the shortest time of the glue is 20 min.

2) The aluminum parts have gone from room temperature to approximately 10 min, the aluminum isolation time is around 20 min and the aluminum recharging time is about 7 min from temperature D ‘100 -part insulation.

Conclusion

Modern cars develop towards the direction of light emissions, at high speed, safe and comfortable, at low cost, low cost and energy saving. With the improvement of awareness of environmental protection, aluminum alloy plates have an unequaled superiority in terms of cost, manufacturing technology, mechanical performance and sustainable development.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.