Preface

Gas insulated switchgear for cabinet (gas insulated switchgear for cabinet, called C-GIS, commonly called inflatable cabinet in my country) is a new high-tech series product developed in the past ten years and has gradually become an important variety of metal products. closed equipment.

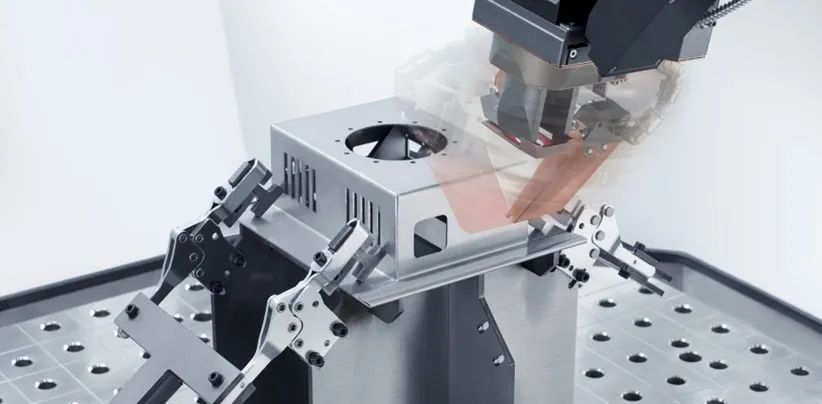

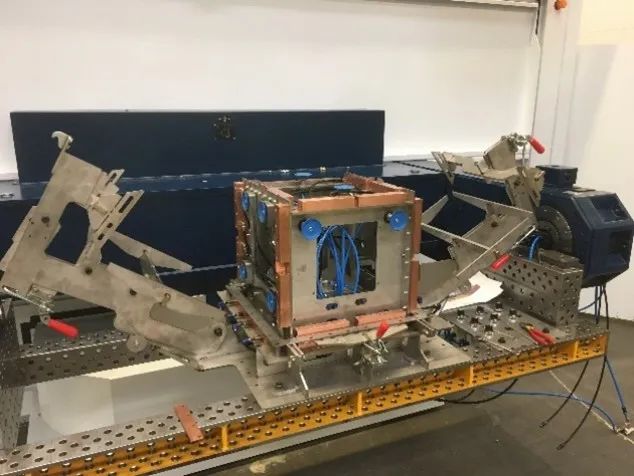

In the field of inflatable cabinet production, TRUMPF offers equipment, plants and application technologies for laser cutting and welding applications. From a variety of welding equipment (TruLaser Cell 7000 series five-axis machine tools/TruLaser Weld 5000 intelligent laser welding system), to optional customized solutions (rich loading and unloading methods), to various welding methods. cabinet assembly (bent parts assembly/flat panel assembly), TRUMPF offers comprehensive and flexible laser welding inflatable cabinet solutions to customers around the world.

The TRUMPF Trulaser Weld 5000 intelligent laser welding system (hereinafter referred to as TLW5000) is an efficient and high-quality solution offered by TRUMPF to customers in the sheet metal industry to apply laser welding technology. It also meets MTO (multi-variety) requirements. , small batch) and MTS (large batch production requirements). Different from the traditional way of processing inflatable cabinets using Trulaser Cell series machine tools, 5000 equipment brings new possibilities for laser processing of inflatable cabinets with good cost performance and excellent flexibility .

Inflatable Cabinet Processing Process Using TLW5000 Equipment

01

Laser cutting

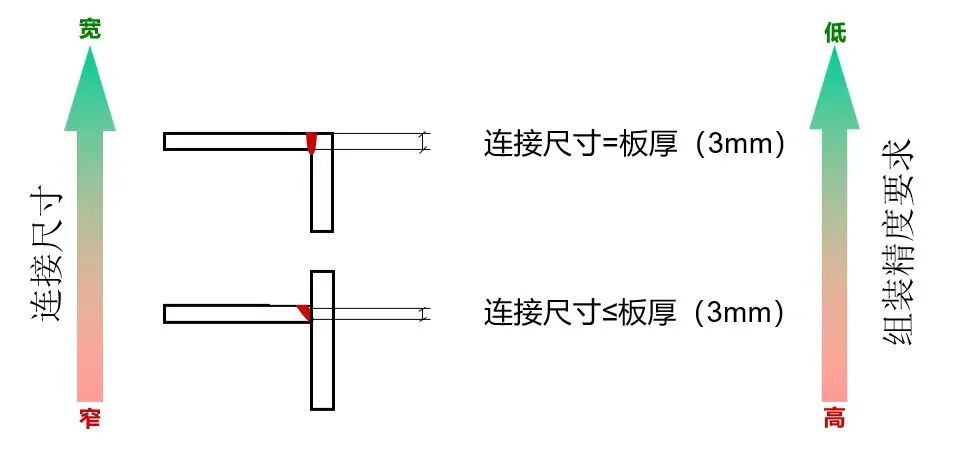

The material of the inflatable cabinet is generally stainless steel plate with a thickness of 3mm. In order to meet the requirement of laser welding that the welding gap should be less than 0.1mm, the edges of the plate should be smooth, without chamfers and without burrs. Therefore, laser cutting and cutting should be used, which is a prerequisite for laser welding of inflatable cabinets.

02

Welding of reinforcing ribs

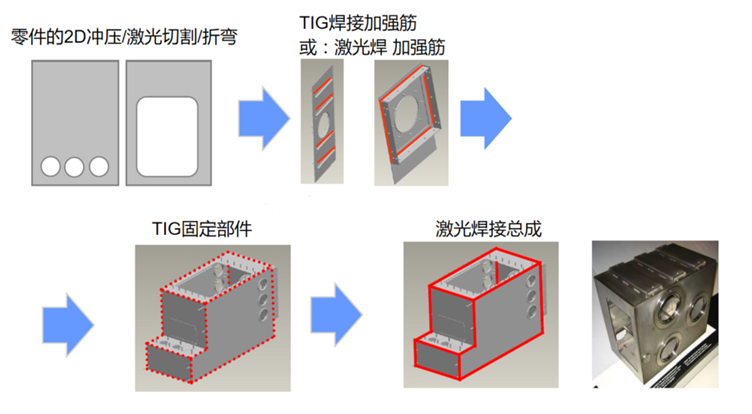

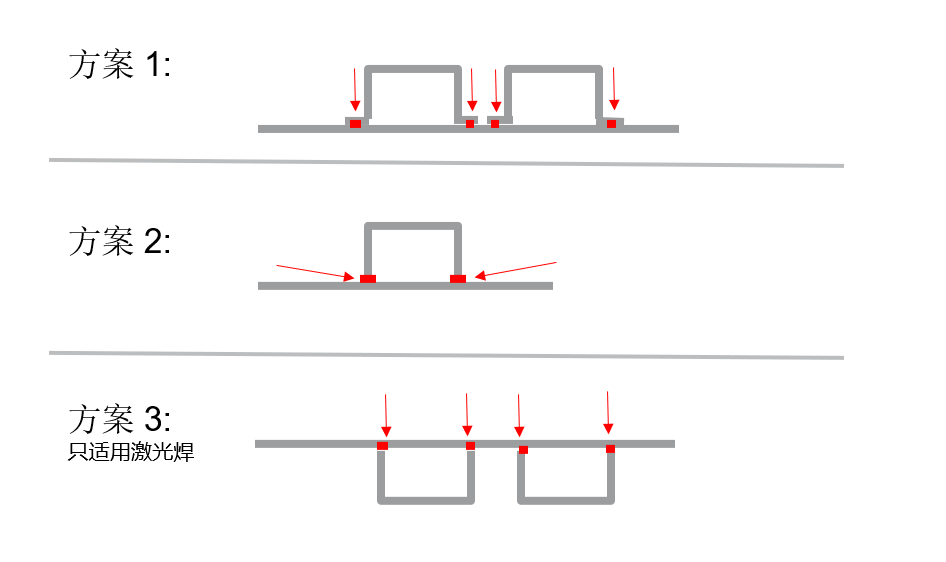

To ensure that the inflatable box will not deform when placed outdoors for a long time, reinforcement ribs should be placed inside the board to increase the strength of the box. According to customer needs, TIG spot welding or intermittent laser welding can be selected. TRUMPF offers three solutions for intermittent laser welding:

03

TIG spot welding cabinet

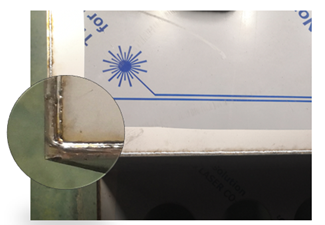

Before the inflatable cabinet is laser welded, the stainless steel side panels must be assembled by argon arc spot welding and then laser welded to ensure airtightness and welding strength .

For the overlapping method between boards, it is recommended to use the type “I” splicing method at the outside corner. Using this splicing method, the welding section between the plates is the largest and the welding strength is the highest. It should be noted that we should try to ensure that the solder gap is less than 0.1mm. This is because the diameter of the laser spot at the focus is about 0.4mm and there is no welding wire in self-fluid welding. The space between the plates is too large, it will cause welding defects resulting in poor airtightness.

04

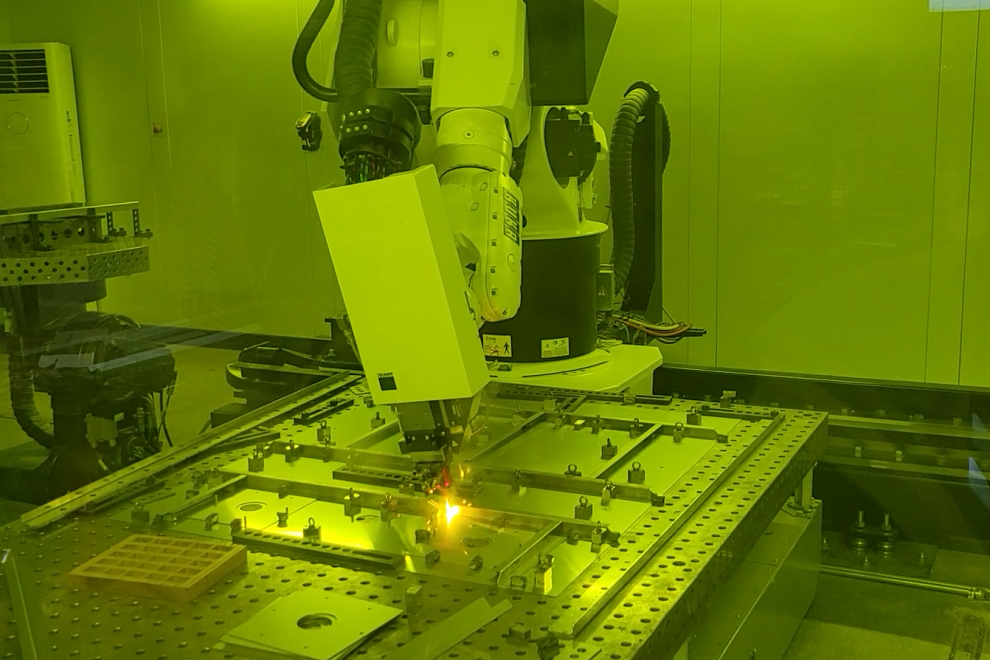

Laser welding inflatable cabinet body

At present, the average welding power of inflatable cabinets is 4 kW, and the welding depth is 3-4 mm. Using TLW5000 can guarantee welding speed from 2.5m/min to 4m/min. Using higher power lasers allows for greater weld depth and faster weld speeds with less thermal distortion. The TruLaser Cell 1005 from the Siemens factory is equipped with a laser with a power of 6 kW.

Advantages of the TLW 5000 device

01

Electric focus system

The main quality issues related to laser welding of inflatable cabinets include: penetration stability, spatter and pores, and corner overheating.

Corner Overfire Box (non-TLW5000)

TLW5000 welding

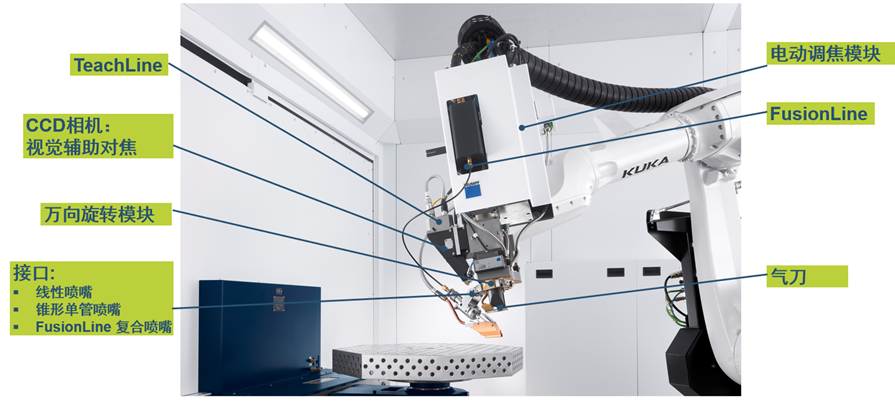

Using TLW5000 intelligent welding system can improve the welding quality of inflatable cabinets. This is mainly due to the set of advanced functional modules integrated into the system, such as visual auxiliary focusing system on the welding head, electrical focusing module, etc. As well as the system’s integrated welding parameter library, production plan management functions, etc.

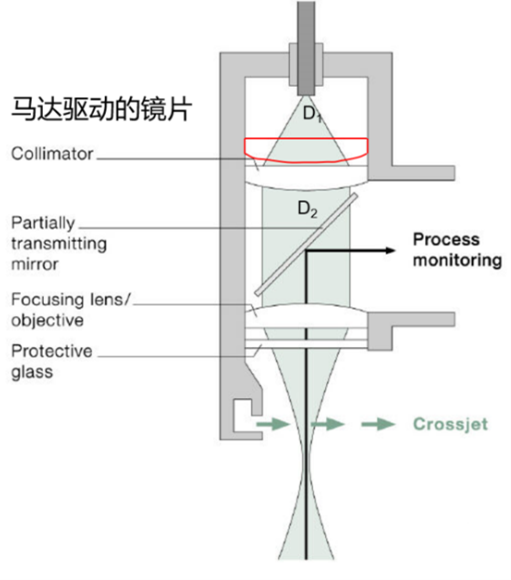

Among them, the electric focusing system can easily realize process switching and ensure stable welding quality.

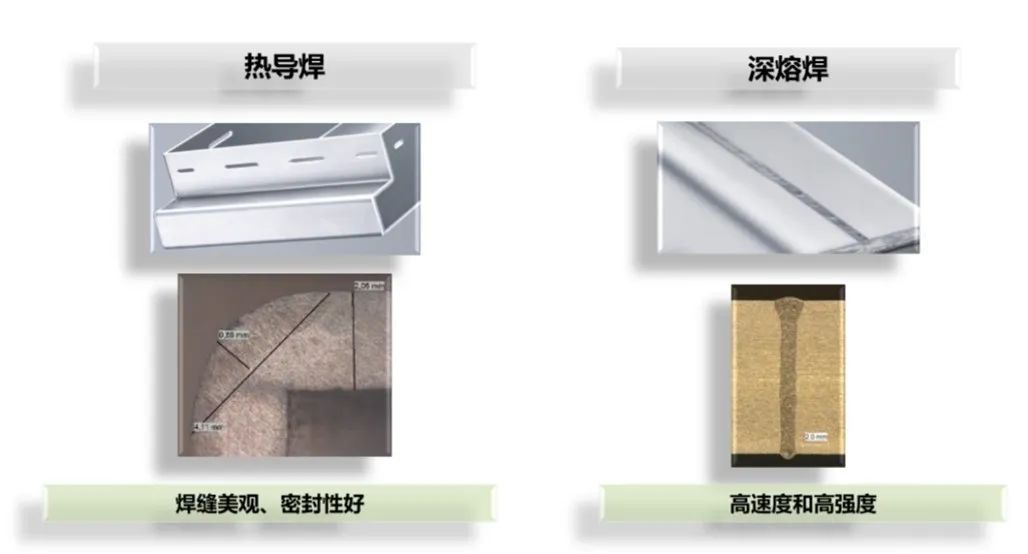

Heat conduction welding and deep penetration welding are two common laser welding processes. Thermal conductive solders are smooth and round, with good sealing properties; deep penetration welds are strong and fast. The focal position is the key to changing the welding process. Each millimeter deviation can cause a sudden change in the quality of the weld.

Some integrated equipment uses simple linear light focusing and adjusts the degree of defocus by adjusting the robot arm. The coarse solution brings coarse welding quality – welding defects such as spatter, pores, cracks, etc. are removed. greatly affect the rate of return.

In order to achieve ultimate precision and stability, the 5000 has abandoned the traditional method of adjusting the focus position by adjusting the mechanical arm. Instead, a high-precision electric focusing lens has been integrated into the welding head. is accurate to 0.1mm, combined with a high-magnification CCD camera to quickly and accurately complete focus positioning, which basically guarantees stable output, greatly reduces programming time and reduces the risk of splashing and cracks during the welding process.

02

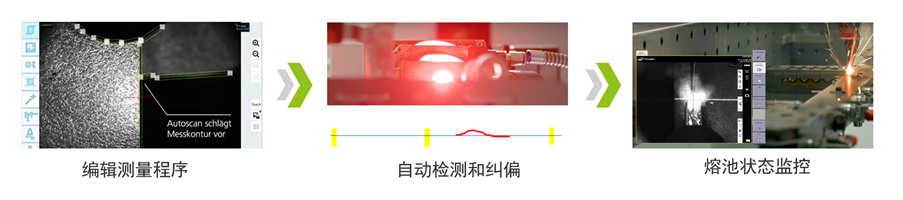

TeachLine Weld Inspection

In order to compensate for the positioning error, sensors are generally used to detect and reposition the position of the product. Common weld inspection methods include on-line inspection and off-line inspection. In the technical path of weld inspection, TLC five-axis three-dimensional machine tools and TLW5000 equipment adopt offline inspection. Compared with online detection, offline detection is not affected by high-intensity arc light during the welding process, has better detection stability, does not increase the computing power burden during the welding process and the welding speed is faster. The difference lies in the physical means to achieve offline detection. The TLC five-axis three-dimensional machine tool uses probe measurement, while the TLW5000 uses the TeachLine visual measurement system.

The TeachLine visual measurement system is a patented feature on the TLW5000 equipment. This feature makes it easy and quick to configure the weld inspection program. Combined with TruTops Weld offline programming software (TLW500 patented function), the weld inspection program can even be set during. offline programming.

03

TruTops Weld Offline Programming Software

In flexible laser welding production, the introduction of new products is often the most burdensome. We have to suspend production for hours or even days to change welding procedures for new products. But when you introduce TruTops Weld offline programming software into TLW5000 device, this problem is solved.

Using the TruTops Weld offline programming software, the welding program can be generated directly on the computer (note that this is the welding program, not just the robot’s movement path). After importing it into the TLW5000, manual teaching or position correction via TeachLine can be performed. quickly put into production.

04

Universal gas nozzle

When laser welding, good nozzle design can prevent oxidation, suppress plasma to ensure stable penetration, reduce spatter and accelerate cooling.

Some integrated equipment uses simple side blow or coaxial nozzles. Compared with coaxial nozzles, side-blowing nozzles can better prevent oxidation of the weld bead and accelerate cooling, but the disadvantage is that it greatly reduces the accessibility of the robot posture and is easily disturbed.

Common household coaxial nozzles

Common Household Side Blow Nozzles

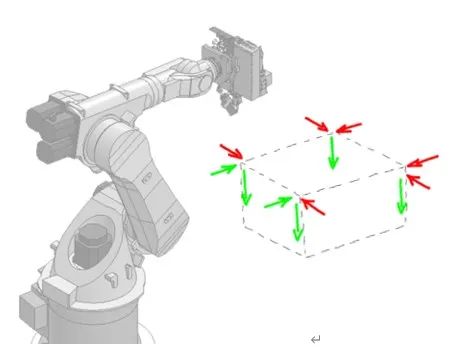

The red arrow represents the place that the side blow nozzle cannot cover

In this regard, TRUMPF has designed a unique universal gas nozzle, which can guarantee the best welding effect while providing the same good accessibility as the coaxial nozzle: thanks to its automatic rotation, it can easily cover the weld in all directions and significantly improve posture accessibility. save programming time.

05

TRUMPF in laser welding

“know how”

The successful application of laser welding technology in the sheet metal industry benefits not only from the powerful TLW5000 equipment, but also from TRUMPF’s comprehensive laser welding design theory system.

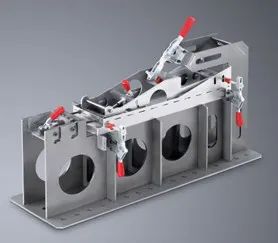

Sheet metal and tooling design courses, which embody TRUMPF’s decades of experience in the sheet metal industry, can support the efficient transition of laser welding technology from single-product prototyping to profitable production .

Automatic clamping tooling for inflatable cabinets (no manual spot welding required)

Exquisite sheet metal tooling improves efficiency several times

Conclusion

The laser is a beast. Releasing the laser is just the beginning of the welding process. Only precise control can evolve the laser from a beast into a controllable tool.

For this reason, the charm of TLW5000 equipment lies not only in producing extremely beautiful weld bead morphology, but also in stability far beyond conventional standards and in process consistency as precise as replicas.

TLW5000, the artist of sheet metal transformation.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.