01

Analysis of CNC machine tool life cycle management system requirements

CNC machine tools, as the country’s most important equipment and main industrial machine, are the most basic and important manufacturing equipment for manufacturing enterprises and represent the core of the country’s competitiveness. Internet core nodes are basic industrial control information facilities and important physical resources for manufacturing companies.

In recent years, the market demand for high-performance CNC machine tools has increased significantly. The factors that limit the development of my country’s machine tool industry toward high-end and intelligence are: ① The machine tool industry has a wide variety of parts and accessories, different structures, heterogeneous multi-source data and uneven data quality, presenting “information islands”, It is difficult to achieve effective information management and data sharing within the company; ② Standards machine tool industry identification analysis is not unified and closed data cannot be interconnected within the industry, nor with higher nodes and interoperability is poor; multi-source heterogeneous equipment at the CNC machine tool processing site, resulting in inconsistent and incompatible protocol standards, making it difficult to implement protocol adaptation, protocol analysis and the vertical integration of the interconnection of CNC machine tools; open and inclusive public service platform, making it difficult for enterprises in the machine tool industry to complement their strengths and integrate their resources, making it difficult to establish good cooperative relationships between enterprises and the regions.

Wuhan Huazhong CNC Co., Ltd. established a secondary node for Internet industrial identification and resolution (machine tool industry) to provide standardized identification coding registration and identification resolution services for enterprises and users in the field of machine tools, and to carry out construction, operation and application work as a secondary node for the machine tool industry and promotion to promote the reasonable circulation and application of industrial big data.

Based on the above demand analysis, this article is based on the high-quality development requirements of intelligent CNC machine tool manufacturing, faced by the machine tool industry, using technologies such as Internet of Things, big data and artificial intelligence, with “machine tool big data” as the core, to establish a health guarantee system for the full life cycle of machine tools. Through the integration of ID analysis system with industrial Internet platform iNC-Cloud and NC-Link, multi-level data centers such as CNC system factories, CNC machine tool factories and end-user factories are established to realize the supply and production of machine tools. , machine tool assembly, defect management, routine maintenance, complete life cycle management, such as regular physical examinations and remote operation and maintenance, promote digital transformation and implementation at the level of companies in the machine tool industry.

02

Architecture of CNC machine tool life cycle management system based on ID analysis technology

2.1 Overall architecture

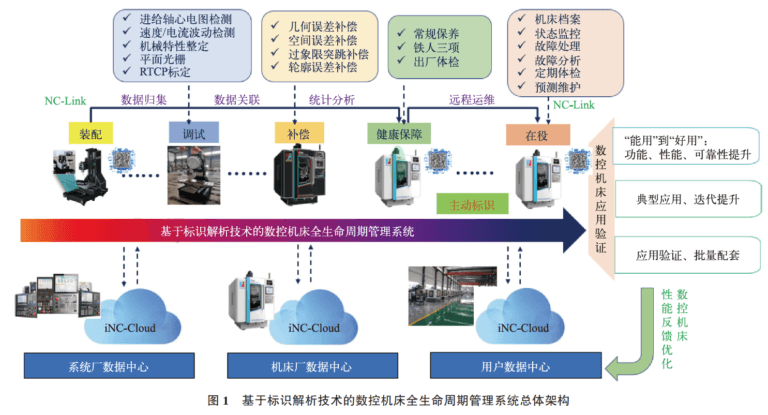

The overall architecture of CNC machine tool life cycle management system based on ID analysis technology is shown in Figure 1. Focusing on issues such as difficulties in traceability of product quality products, paper-based product processes and data integration difficulties in production, manufacturing and machine tool operation, we rely on the iNC-Cloud industrial Internet platform and communication protocol of intelligent workshop interconnection independently developed by Huazhong CNC for NC-Link equipment manufacturing field. and other information technologies, carry out massive data collection and analysis of machine tool storage applications and active identification based on the identification system to complete the vertical integration of machine tool data ; establish three-level data centers such as CNC system, machine tool factory; and the user factory, through machine tool assembly, debugging, compensation, health protection, remote operation and maintenance and other technical research, and realize machine tool development. Integrated product and testing of the full life cycle management system improves the enterprise’s data collection and control analysis capabilities in the production and manufacturing process of machine tools, and helps to open up the links between companies in the research, development and design of machine tools. functional components, production and manufacturing of machine tools, as well as operation and use of the user enterprise. Collaboratively innovate on bottlenecks to achieve horizontal information integration across businesses. Through horizontal and vertical benchmarking of CNC machine tool lifecycle data, optimization of performance feedback, and continuous iterative improvement, CNC machine tools are promoted from “usable” to “easy to use.” use” and help improve the operation, performance and reliability of CNC machine tools. .

2.2 Solutions

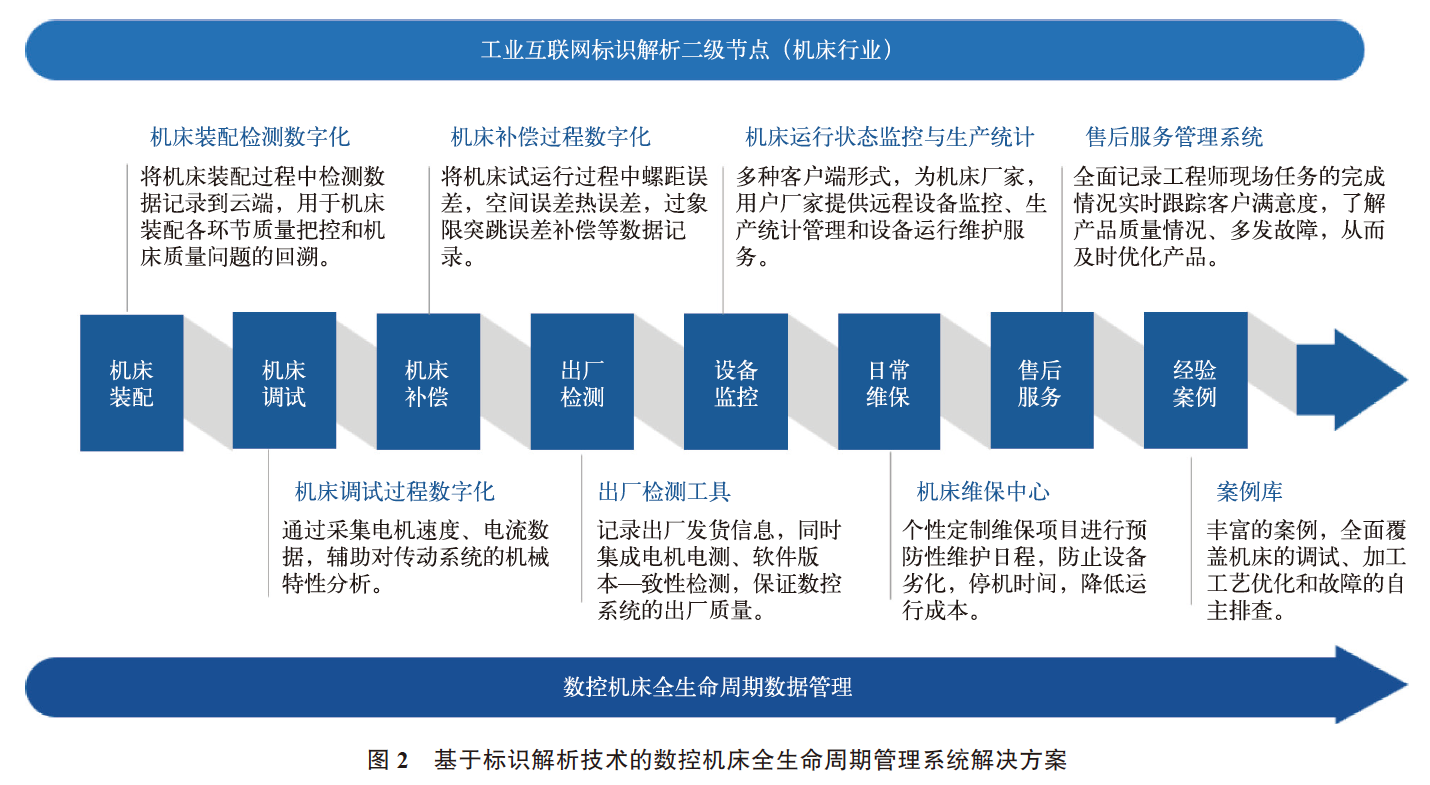

The complete life cycle management system solution of CNC machine tools based on identification analysis technology is shown in Figure 2. With “machine tool life cycle data” as the basis for the system data source management, accurate and reliable data sources are obtained from CNC machine tools and their components as the basis for data analysis for operation and maintenance. They are closely driven by sensory data. the life cycle of machine tools to focus on the entire life cycle of machine tools. The manufacturing life cycle process, with “digital twin of CNC machine tools” as the basic guiding ideology, forms the data collection at each stage of machine tools such as “assembly”. , debugging, compensation, health insurance, operation and maintenance” to improve the performance optimization and product quality feedback of enterprise production machine tools. Among them, the four-in-one ” assembly, debugging, compensation and health protection” refers to the management of the design and manufacturing stages of machine tools. Remote operation and maintenance refers to the management of the use and commissioning stages. scrapping of machines. Integration. Horizontal four-in-one and remote operation and maintenance is carried out on the basis of identification analysis, thereby realizing the management of the entire life cycle of machine tools.

03

System functional module

3.1 Construction of the Tier 3 data center

The third-level data center includes the user enterprise level, the machine tool enterprise level, and the functional component enterprise level data center. At the same time, each data center is also an industrial Internet logo analysis enterprise node and is horizontally integrated with the second-level node. (machine tool industry).

For CNC system companies, establish data centers for machine tool factories and user factories. Through the industrial Internet, CNC system companies can help machine tool factories complete machine tool after-sales services, and can go to user factories to provide targeted and in-depth services, such as optimization of tool life, optimization of spindle operation and intelligence of the CNC system. functions, etc.

For machine tool manufacturers, establish an equipment management data center for machine tool factories. Through the Industrial Internet, machine tool manufacturers can integrate and manage the machine tools they produce, from four-in-one data during the manufacturing process to operation and maintenance data at distance to the customer after leaving the factory. Monitor and manage equipment in a timely manner, meet user maintenance needs, improve equipment quality and manage traceability before machine tools leave the factory, and transform services from passive response to active care after leaving the factory.

For machine tool user enterprises, establish an application verification data center for machine tool full life cycle management system. User companies regard the workshop as a logical unit and can establish an edge computing platform and a private enterprise data warehouse based on the workshop as the standard. When a machine tool fails or before a predictive failure occurs, the edge computing platform is used to perform closed-loop processing within shop floor management, operation and maintenance, as well as production and manufacturing, to improve digital transformation and upgrade capabilities. At the same time, if the user cannot solve the fault of the closed-loop machine tool on site, the operation and maintenance management center can be used to outsource the data dedicated to equipment requiring maintenance. operation and maintenance, which not only protects the company. data information, but also improves the interconnection and interoperability of remote operation and maintenance.

3.2 Construction of the logo analysis system

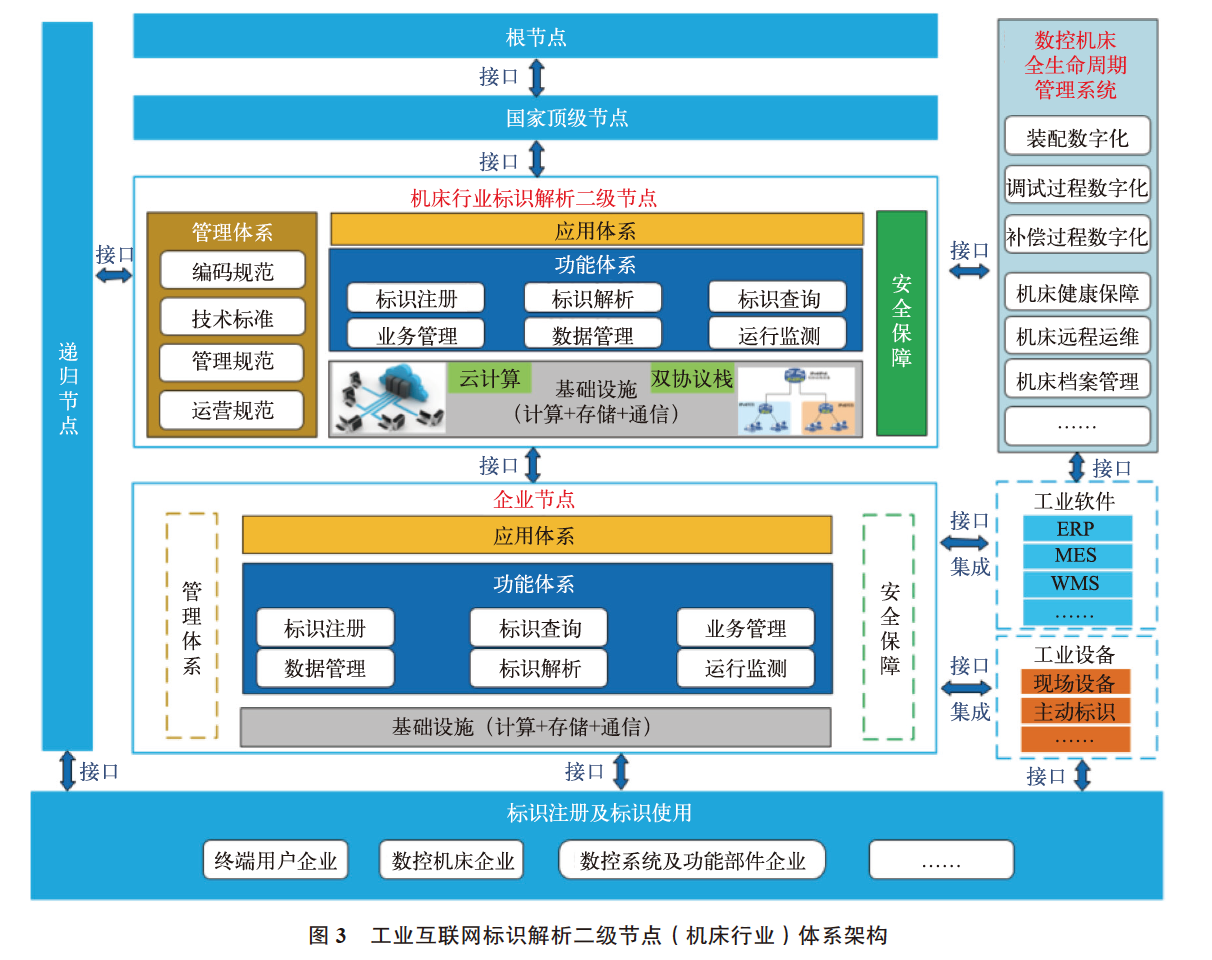

In 2020, Huazhong CNC established a secondary node for industrial Internet identification resolution (machine tool industry), which connects upward to the main national nodes and downward to the enterprise nodes of the machine tool industry. machine tools, providing flexible identification code registration and identification resolution services for businesses. and users in the field of machine tools. Through the collaboration of secondary nodes, data resources, core technologies and open application service platforms, interconnection and interoperability between enterprise nodes, application service platforms Machine tool applications of secondary identification resolution nodes and national top nodes are favored. The platform includes basic facilities, management systems, functional systems and security guarantees, etc. Machine tool industry logo analysis subnode creates a typical and demonstrative industrial internet logo analysis integrated innovative application model, including supply chain management, full machine traceability and components of machine tool equipment and other innovative integrated applications, to realize equipment status, processing conditions and defects. Samples and other data are disseminated and applied throughout the industry under desensitized conditions. The system architecture of the second-level node (machine tool industry) of Internet industrial identification analysis is shown in Figure 3.

3.3 CNC machine tool active marking technology based on NC-Link standard

The NC-Link protocol independently developed by Huazhong CNC is a unified standard protocol for IoT equipment and formed an intelligent factory CNC machine tool interconnection interface specification (GB/T 41970-2022) to realize the interconnection of heterogeneous equipment/modules/systems. /platforms, covering machine tool manufacturing links, functional components and peripheral sensors, and unified analysis and conversion of heterogeneous multi-source data from machine tool equipment and sensor terminals to ‘to the collection of data gateways. The NC-Link protocol achieves the purpose of unifying the interface form, simplifying device access and simplifying application development, and can well meet the interface compatibility requirements for CNC equipment multi-source heterogeneous.

On this basis, an interconnected communication active identification product, an iNC-Box data collection gateway series product, compatible with mainstream CNC machine tools at home and abroad, has been developed, as shown in Figure 4. It is mainly used for communication protocol conversion during the data collection process of industrial CNC machine tools on site and transmits the data to designated data gateways, providing customers with collection capabilities large-scale, high-frequency and low latency, as well as some downstream interaction capabilities. Active identification iNC-Box is divided into three versions: WLAN version, 4G version and WiFi version according to different northbound networking methods. The whole system supports three southbound collection methods: Ethernet, IO and RS485, which can meet the network collection needs of various. industrial sites. At present, it supports many mainstream brands in the market, such as Fanuc, Siemens, Xindai, Mitsubishi, Guangzhou CNC and Kaindi, etc. In addition to internal machine tool data, supported data also includes external devices such as vibration sensors, sound sensors and temperature sensors. The collected data is uniformly translated into the NC-Link protocol and then transmitted to the edge computing system. iNC-Edge for data fusion. The edge computer can be considered the basic node of the enterprise-level data center.

3.4 Horizontal integration of machine tool life cycle management data based on identification

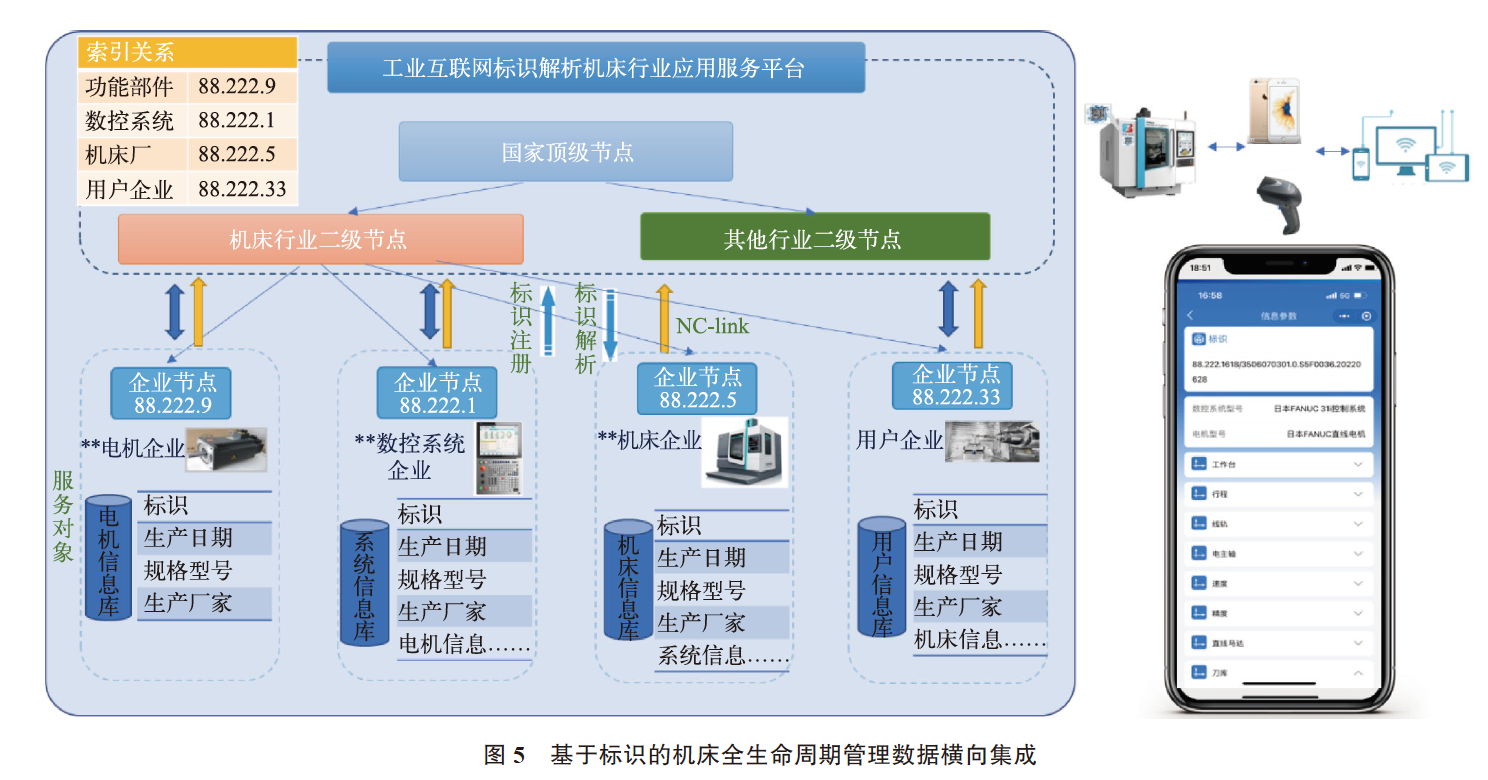

Industrial Internet logo analysis system helps machine tool industry enterprises register and solve the logos of functional components, machine tool products and end-user objects, solve the key problem inconsistent coding and logos of functional components/accessories of the same type of machine tools. between enterprises and realize industrial chain integration. The interconnection of product information between downstream enterprises and the horizontal integration of upstream and downstream data in the industrial chain in the field of machine tool equipment. As shown in Figure 5, around the identification system, the discrete data scattered on the industrial Internet is integrated, and the machine tool data from production, testing, assembly, debugging and l use are integrated and open, targeting the link of use, maintenance. link and remanufacturing link and waste recycling links, and develop new integrated application models for product life cycle management such as quality traceability management and operation and maintenance at machine tool distance to improve the intelligent upgrading of machine tool manufacturing process.

04

Implementation of a complete lifecycle management system for CNC machine tools based on ID analysis technology

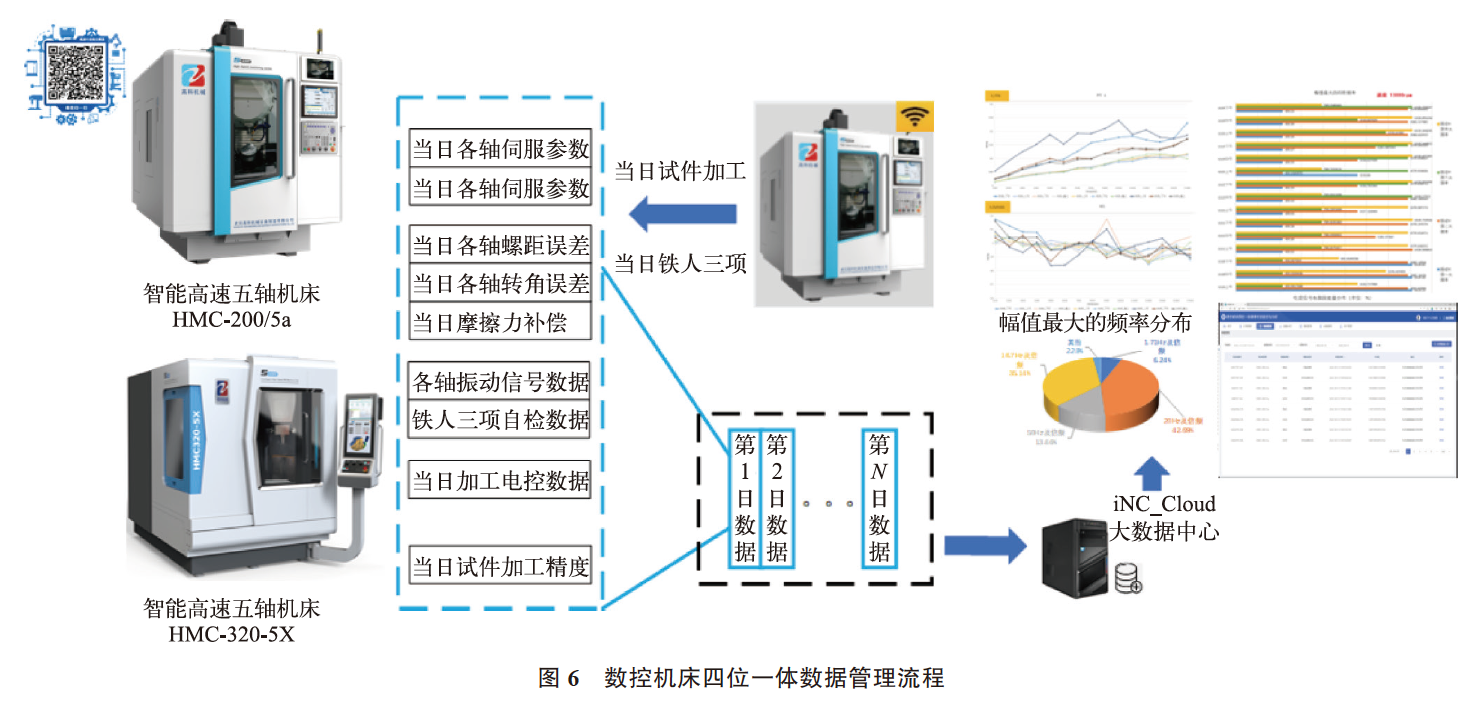

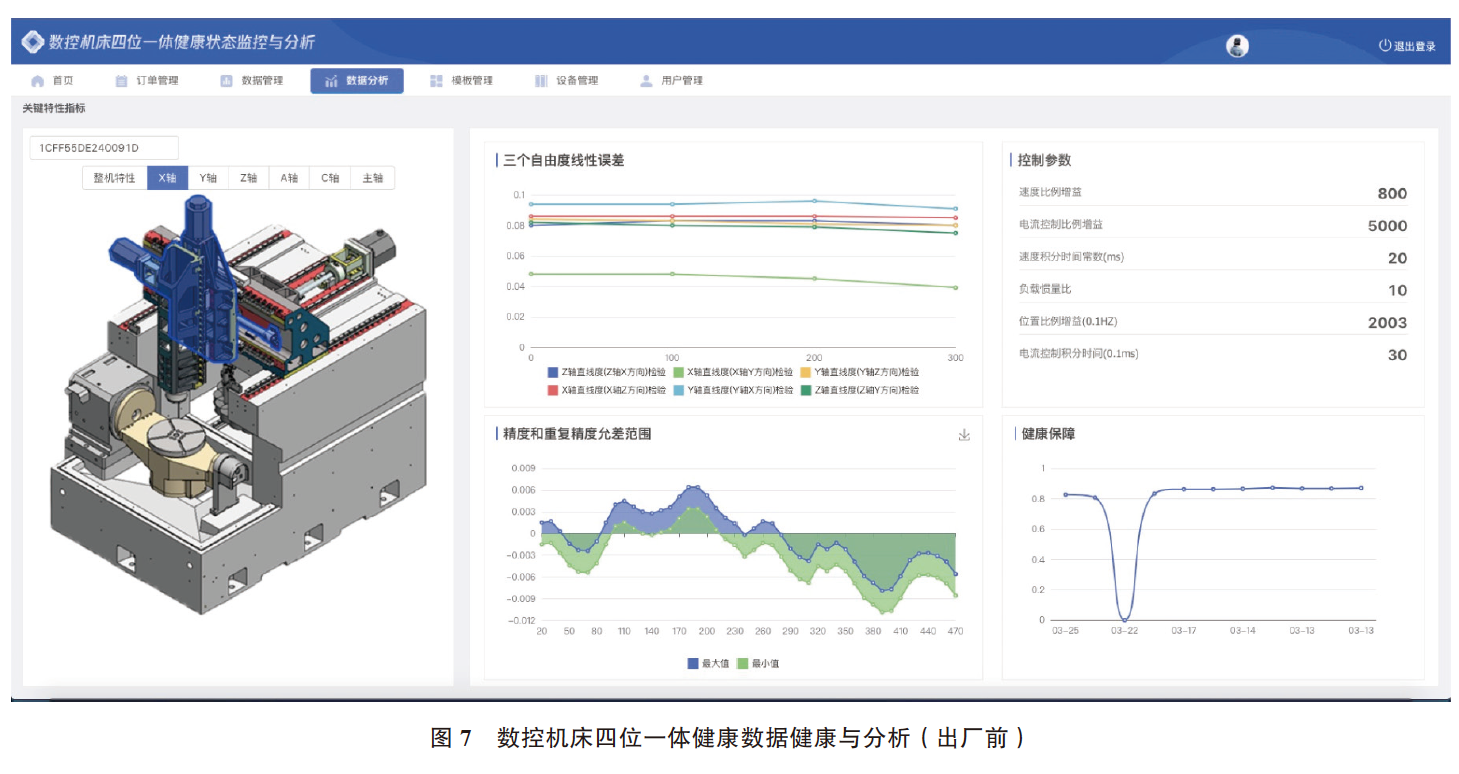

The four-in-one data of CNC machine tools based on identification analysis technology integrates “assembly, debugging, compensation and health protection” surrounding the machine tool manufacturing process. Form a quality evaluation system of CNC machine tool assembly to realize the rapid and efficient collection and analysis of machine tool life cycle data, accelerate problem discovery – analyze problems – solve problems, improve the cycle speed of machine tool performance, thereby obtaining accelerated feedback and optimization of enterprise production machine tool performance Overall improvement. As shown in Figures 6 and 7.

Remote operation and maintenance system of CNC machine tool (after leaving the factory), as shown in Figure 8. It mainly provides data support for remote maintenance applications for manufacturers of CNC machine tool systems, machine tool manufacturers and user factories. Carry out intelligent maintenance of machine tools, such as machine tool file construction, fault monitoring, fault analysis, fault management, regular physical examination and predictive maintenance of CNC machine tools , providing data support and application environment to improve the operation, performance and reliability of high-quality machine tools. end of CNC systems.

The traceability of the entire life cycle of CNC machine tool products, as shown in Figure 9, records the process data of the entire life cycle of the equipment (factory delivery, use, maintenance and repair), forming a knowledge base on the product life cycle. , and optimize the performance of the system or equipment. Provide support for functional improvements, operations and maintenance.

05

Conclusion

High-quality development of CNC machine tools is inseparable from data-driven development. The CNC machine tool life cycle management system based on ID analysis technology realizes the vertical integration of industrial data through the independently controllable NC-Link interconnection communication protocol. At the same time, it integrates with the industrial Internet identification analysis subnode (machine tool industry). ) to realize industrial enterprises, the nodes are horizontally integrated into the data center.

Focusing on the different stages of CNC machine tools before and after leaving the factory, we will realize model innovation and transformation of the full life cycle management of equipment such as four-in-one machine tools and remote operation and maintenance. According to user statistics in 2022, the troubleshooting efficiency of machine tools increased by 13%, equipment maintenance efficiency and costs improved by 8%, the user’s independent processing rate improved by 8%. reached 6%, and the composite utilization of expert resources increased by 15%, etc., greatly improving the quality and efficiency of machine tools.

This article is based on the demand for intelligent manufacturing of machine tool equipment to improve the safety performance of industrial mother machines and ensure national information security. It has been successfully applied in many industries such as mechanical processing, electronic products, household appliances and energy equipment. , and is very important to promote the automation and intelligence of the entire discrete industry level, with significant technical value and demonstration effect.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.