The English word for screw is Screw. The meaning of this word has changed considerably over the last few hundred years, at least in 1725 it meant “mating”.

The application of the thread principle dates back to the spiral water-lifting tool created by the Greek scholar Archimedes in 220 BC.

In the 4th century AD, countries around the Mediterranean began to apply the nuts and bolts principle in presses used for winemaking. At this time, the outer wires were wrapped with rope around a cylindrical bar and then carved according to the mark, while the inner wires were often wrapped in softer materials and hammered into shape.

Around 1500, in the sketch of a thread processing apparatus drawn by the Italian Leonardo da Vinci, there was the idea of using a female screw and an interchange gear to process threads with different pitches. Since then, the mechanical tapping method has developed in the European watch industry.

In 1760, the English brothers J. Wyatt and W. Wyatt obtained a patent for cutting wood screws with a special device. In 1778, the Englishman J. Lumsden constructed a thread cutting device driven by a pair of worm gears, capable of processing long threads with high precision. In 1797, Englishman H. Maudsley turned metal threads with different pitches using a female screw and interchange gear on a lathe he improved, thus laying the basic method for turning the threads.

In the 1820s Maudsley manufactured the first taps and dies for processing threads.

At the beginning of the 20th century, the development of the automobile industry promoted the standardization of threads and the development of various precise and efficient thread processing methods. Various automatic opening die heads and automatic retracting taps were successively invented, and thread milling began to develop. be applied.

At the beginning of the 1930s, thread grinding appeared.

Although thread rolling technology was patented in the early 19th century, its development was slow due to the difficulties of mold making. It was not until after World War II (1942-1945) that the need for weapons production and the development of thread grinding technology were resolved. The problem. The issue of precision in mold making has developed rapidly.

Wires are mainly divided into connection wires and transmission wires

To connect wires, the main processing methods are: tapping, threading, turning, thread rolling, thread rolling, etc.

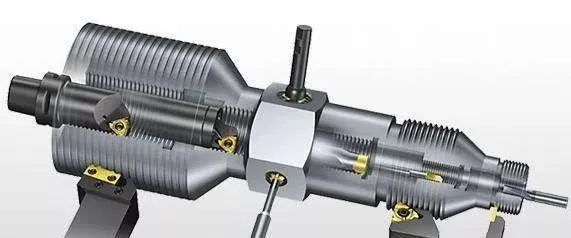

For transmission threads, the main processing methods are: rough and fine turning – grinding, cyclone milling – rough and fine turning, etc.

The first category: threading

Generally refers to the method of processing threads on the workpiece using forming tools or grinding tools, mainly including turning, milling, thread tapping and grinding, grinding and cyclonic cutting. When turning, milling and grinding threads, every time the workpiece rotates, the transmission chain of the machine tool ensures that the turning tool, milling cutter or grinding wheel moves one step accurately and evenly along of the axial direction of the part. When tapping or threading, the tool (tap or die) and the workpiece perform relative rotational movement, and the formed threaded groove first guides the tool (or workpiece) to move axially.

1. Thread turning

The threads can be turned on a lathe using a forming tool or a thread comb. Turning threads with a forming turning tool is a common method for producing threaded parts in one piece and small batches due to its simple tool structure; Turning threads with a thread comb tool has high production efficiency, but the tool structure is complex and is only suitable for medium and large series production. Turning fine-threaded parts with short threads. The pitch accuracy of trapezoidal thread turning with ordinary lathes generally can only reach level 8 to 9 (JB2886-81, the same below); When threads are processed on a specialized thread lathe, productivity or accuracy can be significantly improved.

2. Thread milling

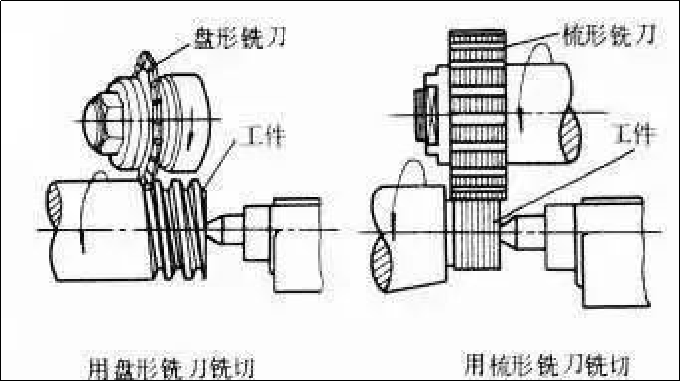

Milling is carried out on a thread milling machine with a disc cutter or comb.

Disc cutters are mainly used for milling trapezoidal external threads on threaded rods, worm screws and other parts. Comb cutters are used for milling internal and external ordinary threads and taper threads. Since they are milled with a multi-edged cutter and the length of the working part is greater than the length of the thread to be processed, the workpiece only needs to be machined. be turned 1.25 to 1.5 turns to process complete and very productive. The pitch accuracy of thread milling can generally reach level 8 to 9, and the surface roughness is R5 to 0.63 microns. This method is suitable for batch production of threaded parts with general precision or rough machining before grinding.

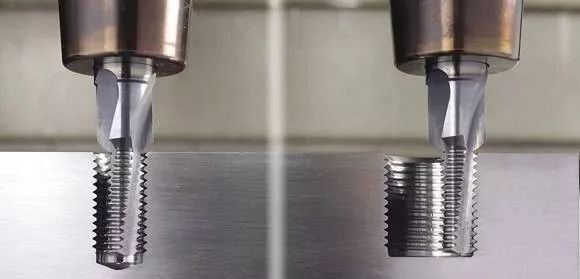

Thread milling cutter dealing with internal threads

3. Wire grinding

It is mainly used for processing precision threads of hardened parts on thread grinders. According to the different cross-section shapes of grinding wheels, it can be divided into two types: single-line grinding wheel and multi-line grinding wheel. The pitch accuracy that can be achieved by grinding a single-line grinding wheel is 5-6 levels, and the surface roughness is R1.25-0.08 microns. Dressing the wheel is more practical. This method is suitable for grinding precision screws, thread gauges, lead screws, small batches of threaded parts and relief grinding of precision hobs. Multi-line grinding wheel grinding is divided into two types: longitudinal grinding and plunge grinding. The width of the grinding wheel in the longitudinal grinding method is less than the length of the wire to be ground. The grinding wheel can be moved longitudinally one or more times to grind the wire to the final size. The width of the grinding wheel of the plunge grinding method is greater than the length of the wire to be ground. The grinding wheel cuts the surface of the workpiece radially. The workpiece can be ground in approximately 1.25 revolutions. but the precision is slightly lower and the dressing of the grinding wheel is more complicated. The plunge grinding method is suitable for relief and grinding of large series of taps and grinding of some threads for fastening.

4. Wire grinding

Nut or screw type thread grinding tools are made from soft materials such as cast iron. The parts of the processed threads on the workpiece that have pitch errors are ground in forward and reverse rotation to improve the pitch accuracy. Hardened internal threads are usually ground to eliminate distortion and improve accuracy.

5. Tapping and threading

Tapping

It uses a certain torque to screw the tap into the pre-drilled bottom hole on the workpiece to process the internal thread. Threading

The die is used to cut external threads on the bar (or pipe) workpiece. The processing accuracy of tapping or threading depends on the accuracy of the tap or die.

Although there are many methods for processing internal and external threads, small diameter internal threads can only be processed with taps. Tapping and threading can be done manually, or lathes, drill presses, tapping machines and threading machines can be used.

The second category: thread rolling

A processing method that uses a forming rolling mold to plastically deform the part to produce threads. Wire rolling is usually carried out on a wire rolling machine or automatic lathe equipped with an automatically opening and closing wire rolling head. Suitable for mass production of external threads for standard fasteners and other threaded connections. The outer diameter of rolled wires generally does not exceed 25mm, and the length does not exceed 100mm. The thread accuracy can reach level 2 (GB197-63). The diameter of the blank used is approximately equal to the original diameter of the. thread being processed. Rolling generally cannot process internal threads, but for softer parts, grooveless extrusion taps can be used to cold extrude internal threads (the maximum diameter can reach about 30mm). The principle of operation is similar to tapping. The torque required for cold extrusion of internal threads is about twice that of tapping, and the processing accuracy and surface quality are slightly higher than that of tapping.

Advantages of thread rolling: ① The surface roughness is lower than that of turning, milling and grinding; ② The strength and hardness of the thread surface after rolling can be improved through cold hardening; ③ The material utilization is high; easy to achieve cutting processing and automation ⑤The rolling die has a long service life. However, wire rolling requires that the hardness of the workpiece material does not exceed HRC40; the dimensional accuracy of the blank is high; the precision and hardness requirements of the rolling mold are also high, making the mold manufacturing difficult; suitable for rolling wires with asymmetrical tooth shapes.

According to the different rolling dies, thread rolling can be divided into two types: thread rolling and thread rolling.

6. Rolling yarn

Two thread shaping plates with threaded teeth are arranged relative to each other with an offset pitch of 1/2, the static plate is fixed, and the moving plate performs reciprocating linear movement parallel to the static plate. When the part is advanced between the two plates, the moving plate advances and rubs the part, causing plastic deformation of its surface to form threads (Figure 6).[搓丝])。

7. Thread rolling

There are three types: radial thread rolling, tangential thread rolling and rolling head thread rolling.

① Radial thread rolling: 2 (or 3) thread rollers are installed on parallel shafts, the workpiece is placed on the support between the two rollers, and the two rollers rotate in the same direction and at a constant speed (Figure 7 [径向滚丝]), one of which also performs a radial advance movement. The part rotates, driven by the rolling wheel, and the surface is extruded radially to form threads. For some screws that do not require high precision, similar methods can also be used for profiling.

②Tangential thread rolling: Also known as planetary thread rolling, the rolling tool consists of a rotating central rolling wheel and three fixed arc-shaped thread plates (Figure 8).[切向滚丝]). During thread rolling, the workpiece can be fed continuously, so the productivity is higher than that of thread rolling and radial thread rolling.

③Thread rolling head: It is carried out on an automatic lathe and is generally used to process short threads on the workpiece. There are 3 to 4 rolling wheels in the rolling head distributed evenly around the periphery of the part (Figure 9[滚丝头滚丝]). During thread rolling, the part rotates and the rolling head advances axially to roll the part off the thread.

8. EDM wire processing

Ordinary thread processing generally uses machining centers or tapping equipment and tools, and sometimes manual tapping can also be used. However, in some special cases, the above method is not easy to achieve good treatment results. For example, due to negligence, the thread needs to be processed after heat treatment of the workpiece, or due to material factors, such as necessity. to tap directly on the carbide part. At this point, you need to consider the method of processing EDM.

Compared with the machining method, the order of EDM is the same, the bottom hole should be drilled first, and the diameter of the bottom hole should be determined according to the working conditions. The electrode must be made into a wire shape and must be able to rotate during treatment.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.