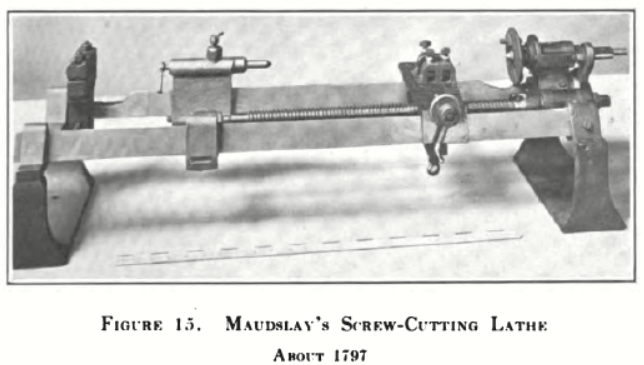

As a type of machine producing machine, machine tools are known as the cornerstone of industrial modernization, but machine tools with true industrial dimension did not appear after the industrial revolution. As early as 2,000 years ago, carpenters used the elasticity of branches and the rotation of ropes to make simple mechanical cutting parts. In the 15th century, threading lathes and gear machining machines for making clocks and weapons appeared in Europe, along with water-powered machines. Driven barrel boring machines. In the Ming Dynasty, the grinder used to cut jade is also recorded in “Tiangong Kaiwu”. But even in the 18th century, when the spinning machine and the steam engine appeared, machines were still made manually using manual workshop methods, which lagged far behind mechanized production in the modern sense. It was not until 1797 that Henry Maudsley manufactured a precision machine tool, which took a breakthrough in the processing of precision parts and officially opened the era of machine production machines.

Henry Maudslay (1771-1831) was born into a military family in Woolwich, England, on August 22, 1771. After his father was discharged due to injury, he became a “technician” at the Royal Arsenal in Woolwich (then in Kent). Maudsley did not receive a formal education as a child. He inherited his father’s business and entered the armory at the age of 12 to be responsible for loading gunpowder. At age 14, he changed careers and apprenticed to a carpenter. Due to his interest and love of machinery, Maudsley eventually persuaded his parents to go to the blacksmith shop and became an apprentice at the age of 15. While working in the blacksmith shop, Maudsley mastered several manual techniques that constitute the basic skills of a machinist. Among them, his ability to use files is the best. Several years of working as a blacksmith allowed him to acquire excellent skills and accumulate a good reputation. . At that time, locksmiths and watchmakers were both popular professions in society. Because with the continuous improvement of people’s living standards, homes and factories had to be locked to prevent theft; At this time, many people used clocks and other items that only the upper classes could own in the past. Thus, just after the 18th century, many locksmiths and watchmakers appeared across Europe. In the UK, security lock manufacturer Joseph Bramah is undoubtedly the industry leader. Because Brahma was an authority on mechanical manufacturing technology, his factory became the place to which anyone who wanted to become a true machinist aspired. This was of course very attractive to Maudsley, who was already mechanically gifted. So at the age of 18, Maudsley submitted his application to Bramah. Bramah asked Maudsley to complete several assessment tasks. Brama found that Mozley had performed perfectly on various technical evaluation projects he had proposed and decided to hire Mozley. At the Bramagh factory, Maudsley showed his talent, and a year later the nineteen-year-old was appointed director of the Bramah studio.

When manufacturing the locks, Maudsley noticed such a problem: in order to meet the demand, if the manual method of making the locks was used, the production would not be able to meet the demand. At the same time, he also thought about the need for machinery to achieve mass production. However, the lathes of the time could not meet the production needs of the lock factory because they lacked an important component such as a power box. So Mozley began to improve existing machine tools. When Maudsley began working for Brahma, the typical lathe was machined using a treadle and the lock shaft was precisely made into a cylindrical shape. The old method relied on the skills of the workers to achieve this. For hundreds of years, the auxiliary tools they used were pedal lathes and turning tools held in their hands. Once the part is tightened, it is pulled by a rope to rotate. One end of the rope is attached to the spring pendulum, the other end is attached to the pedal, and the turning tool is pressed onto the workpiece by hand. This method is suitable for turning, but not at all for metal processing. Since the direction of rotation is constantly changing, it is difficult for manual tools to achieve precise and stable processing. Therefore, Maudsley improved the trick. He replaced the pedal and spring pendulum with a wheel driven by a steam engine via a drive shaft.

Maudsley’s main improvement is the tool holder. The tool is no longer held in the worker’s hand, but is fixed on the tool holder. The tool is brought to the workpiece using two screws and can also move parallel to the axis of rotation of the workpiece. The lathe only needs to operate the handle. The tool holder saves the lathe from the hard physical work of pressing and handling the tool. What is more important is that the tool holder can greatly improve the machining precision and will not cause shaking or impact due to unintentional lathe movements or muscle contractions. Previously, it was rarely possible to machine a mirror-smooth surface without pitting. Today, any turner can do it. The treadle lathe which required skilled operational skills eventually evolved into a turning machine tool. With lathes, it is possible to supply the mechanism manufacturing industry with urgently needed precision parts. At the Bramah factory, Maudsley also helped Bramah solve sealing problems on the hydraulic presses. In 1797, after working for Bramah for eight years, the 26-year-old Maudsley resigned due to salary problems and started his own business, establishing his first factory. Thanks to the excellent quality of its products, the Maudsley factory enjoyed a high reputation among customers and orders poured in one after another. Thanks to his high skills, the small factory prospered quickly. In 1810 Maudsley employed 80 workers. moved to larger premises in Westminster Bridge Road, Lambeth. Maudsley also recruited a promising young draftsman from the Admiralty, Joshua Field. He proved so talented that Maudsley invited him to become a partner and established the Maudsley Field Chamber of Commerce, which suddenly morphed into a machine tool manufacturer. Maudsley paid great attention to the invention. He designed a new engraving machine for boiler steel sheets, etc., so that the manual engraving process of the past would be replaced by machines. In order to improve production efficiency, especially processing quality, Maudsley further improved the machine tool and developed the first industrially practical thread lathe in 1800. Through his own invention of the feed box and the machine installed on the lathe, the screws mesh and advance automatically. Compared with previous thread processing machine tools, very precise threads can be processed. Several gears are used to connect the main shaft and the screw. After the machine starts, the rotation of the gear drives the screw to rotate. By simply changing gears of different sizes, the speed of the screw can be changed, so that. screws with different pitches can be automatically processed. Maudsley’s invention was made and assembled by his disciples Clement and Whitney.

Maudsley married in 1791 and had four sons: Thomas Henry, the eldest, and Joseph, the youngest, who later joined his father in business. The second William became a civil engineer and one of the founders of the Institution of Civil Engineers.

Towards the end of his life, Maudsley became interested in astronomy and began building a telescope. He planned to buy a house in Norwood and build a private observatory there, but he died before his plans could be realized. In January 1831 he caught a cold while crossing the English Channel after visiting a French friend. He remained ill for four weeks and died on 14 February 1831. He is buried in St Mary Magdalen Woolwich Cemetery; he designed the Notre-Dame church memorial. Maudslay laid the foundation for the industrial revolution with his machine tool technology. His most notable invention was the threading lathe. The machine achieved the consistency of screws and enabled the use of interchangeable parts (a prerequisite for mass production), a revolutionary development necessary for the industrial revolution.

His workshop produced many distinguished engineers, including Richard Roberts, David Napier, Joseph Clement, Sir Joseph Whitworth, James Nasmyth (the inventor of the Author steam hammer), Joshua Field. Maudsley played an important role in the development of early mechanical engineering, but he was particularly pioneering in the development of machine tools for use in engineering workshops around the world.

Because Maudsley made a huge contribution to humanity in the development of lathes, not only lathes but other machine tools can also be manufactured with high precision. After entering the 19th century, the machine tool industry developed rapidly, which also promoted the development of machine manufacturing and mass production. Because of Maudsley’s significant contribution, he was called the “Father of the Lathe” or the “Father of the Machine Tool” by later generations.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.