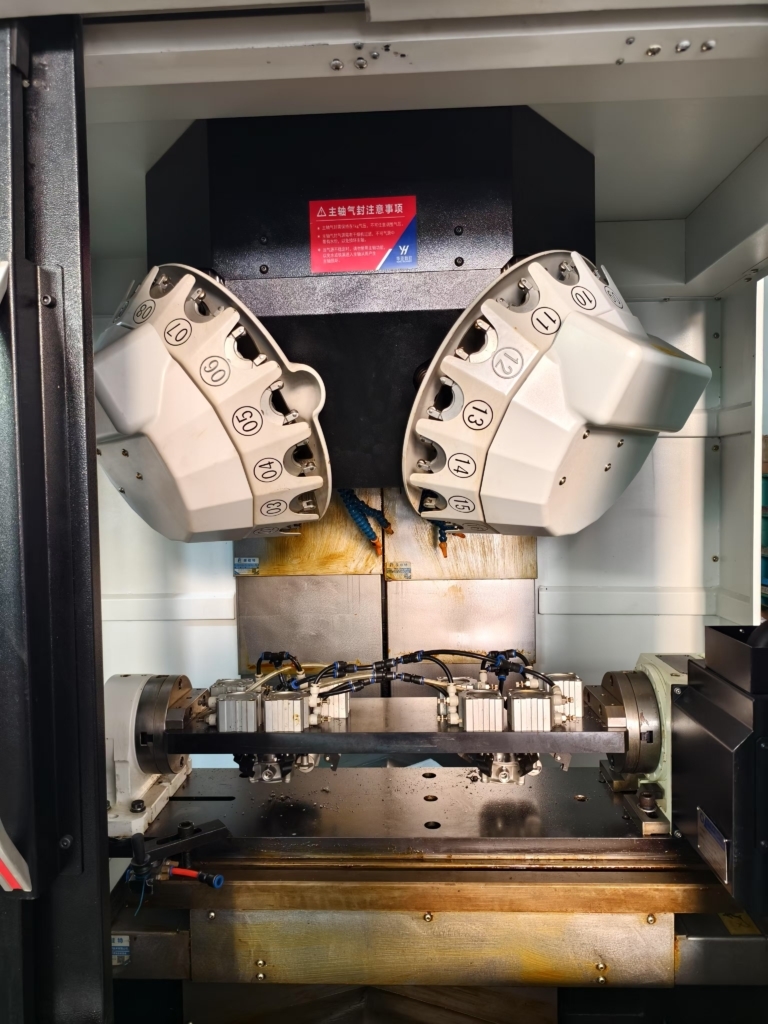

What does the maintenance cost of a twin-spindle machining center generally include? In modern manufacturing, double pinsmachining centerWith its efficient and precise processing capabilities, it has become a key equipment for many enterprises to improve production efficiency and product quality. However, the stable operation of equipment is inseparable from continuous maintenance, and maintenance inevitably involves costs. The maintenance cost of a twin-spindle machining center generally covers the following important parts.

The first is parts replacement costs. The essential components of a dual spindle machining center, such as spindle, screw, guide rail, etc., will inevitably wear out under high-intensity and long-term operation. When the wear of these parts reaches a certain level, they must be replaced. For example, as a key component of a machining center, the precision of the spindle directly affects the processing quality. Once the spindle is severely worn, the replacement cost is usually high. The cost of replacing screws and guide rails cannot be underestimated. High-precision screws and guide rails are expensive, and this cost accounts for a large part of the maintenance cost.

Tracking the cost of consumables such as lubricants and cutting fluids. In order to ensure the normal operation of the equipment, the double spindle machining center should regularly add lubricating oil to reduce the friction between moving parts and extend the life of the equipment. Cutting fluid plays the role of cooling, lubrication and chip removal during the machining process. It consumes a lot and needs to be replenished or replaced frequently. Even if the unit price of these consumables is not high, they nevertheless represent a considerable expense if accumulated over a long period.

Then there is the cost of maintenance labor. When a double spindle machining center breaks down, professional maintenance personnel are needed for inspection and maintenance. The technical level and experience of professional maintenance personnel directly affect the efficiency and quality of maintenance, and their labor costs are relatively high. Especially for some complex faults, troubleshooting and repair may take a lot of time and energy, which will undoubtedly increase the maintenance labor cost.

Additionally, the cost of regular maintenance and testing of equipment cannot be ignored. To ensure that the equipment is always in optimal operating condition, the twin-spindle machining center must be maintained regularly: cleaning, tightening, adjustment, etc. At the same time, professional testing equipment is also necessary to test the accuracy and performance of the equipment. Although these maintenance and inspection tasks are not performed frequently, the cost each time is relatively high.

The maintenance cost of a dual spindle machining center is an overall expense, covering many aspects such as parts replacement, consumables, maintenance labor and maintenance inspections. When companies use dual-spindle machining centers, they must fully consider these maintenance costs and establish budgets and management to ensure stable operation of the equipment and improve production efficiency.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.