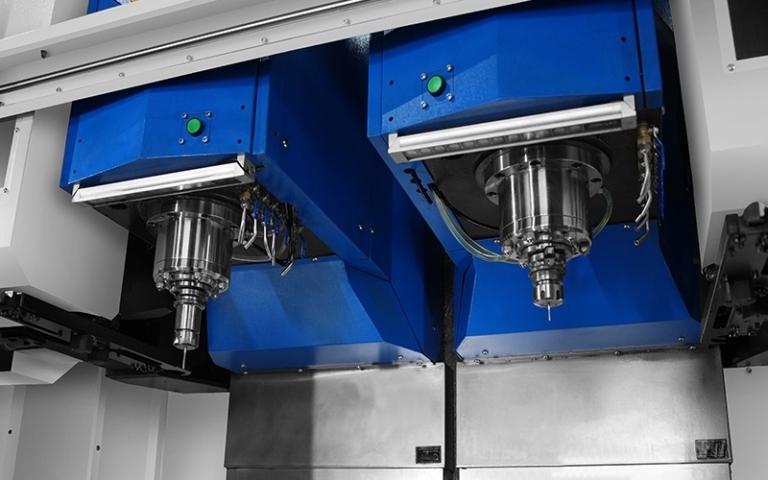

How to clean the cutting tools of a twin-spindle machining center? Cleaning the cutting tools of a twin-spindle machining center is an important step to guarantee machining precision and extend tool life. Here are some specific cleaning steps and considerations:

1. Preparation before cleaning

Turn off the power: Before any cleaning work, be sure to turn off the main power switch of the machine tool and ensure that the machine tool is turned off to avoid electric shock accidents.

Prepare the tools: prepare a clean cotton cloth or special cloth, a vacuum cleaner or air gun (for cleaning hard-to-reach corners), detergent suitable for machine tool materials, lubricating oil and grease, screwdrivers, wrenches and other tools (for removal and installation). protective cover and other parts).

2. Cleaning Steps

To clean the tool surface:

Use a clean cotton cloth or wipe to wipe the surface of the tool to remove dust and oil.

Be careful not to use cleaners containing corrosive substances to avoid damaging the tool surface.

Clean the tool magazine and tool arm:

Open the protective cover of the machine tool and use a vacuum cleaner or pneumatic gun to clean dust and chips from the tool magazine and tool arm.

Pay special attention to cleaning the tool arm, tool magazine and other parts of the tool magazine. These parts are prone to accumulation of dust and chips, affecting the accuracy and life of the machine tool.

Clean the guide rails and lead screw:

Use a brush and detergent to clean chips and dust from the surface of the guide rails and screws.

After cleaning, apply an appropriate amount of oil or grease to reduce friction and wear.

Check the condition of the tool:

During the cleaning process, inspect the knives for wear, damage, or rust.

If necessary, promptly replace worn or damaged tools.

3. Precautions

Safety First: During the cleaning process, be sure to follow the safe operating procedures of the machine tool to ensure personal safety and normal operation of the machine tool equipment.

Regular cleaning: It is recommended to regularly clean and maintain the cutting tools of the twin-spindle machining center to maintain their good working condition and processing precision.

Anti-rust treatment: After cleaning, carry out anti-rust treatment on the cutter, such as applying anti-rust oil, etc. to prevent the cutter from rusting during storage.

Professional maintenance: For complex cleaning and maintenance work, it is recommended to entrust the operation to professional machine tool maintenance personnel or technicians.

In summary, cleaning the tools of a twin-spindle machining center requires following certain steps and precautions to ensure the cleaning effect and normal operation of the machine tool equipment.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.