The broaching gear manufacturing process takes place on the broaching machine equipment. The rack is positioned in the jaws of the clamping body then hydraulically clamped onto the spindle base. Driven by hydraulic cylinder or high-power servo motor. the spindle pulls the sharpening support. During the broaching process, a large amount of cooling oil flushes the broaching area, which not only cools the workpiece and the broaching tool, but also removes a large amount of iron shavings. After the spindle reaches the end of the stroke, a signal is sent, the clamp is released, the bracket is removed, the spindle quickly returns to the starting point, the cooling oil is cut off, and the second bracket is loaded to enter. the next treatment cycle.

Broaching gear processing has many advantages such as high production efficiency, high dimensional accuracy, good dimensional stability and good economy. It is widely used in mass production, such as Shanghai ZF Steering System Co., Ltd., Suzhou Mandu Chassis Components Co., Ltd., FAW Guangyang Steering Equipment Co., Ltd., etc. all use pinout to produce media.

Rack broaching equipment

According to the direction of movement of the pin, the installation method of the pin and the clamping direction of the bracket, it can be divided into the following three broaching methods: First, vertical broaching. The pin moves up and down to process the rack teeth, and the rack is tightened horizontally. The second is Wola. The spindle moves left and right, the rack is clamped horizontally above the spindle, the spindle is installed horizontally on the tool holder, and the broaching edge faces the rack upwards. The third is the side pull. The spindle moves left and right, the bracket is clamped vertically in the bracket, and the spindle is installed sideways on the spindle seat.

Rack and pinion broaching machines generally include the equipment body (including bed, guide rail, tool holder, clamp body and other components), cutting oil tank of the workpiece and circulation system, cooling system to cool the cutting oil, hydraulic drive (or motor drive) system, chips. Removal devices, hydraulic systems, lubrication systems, electrical control systems and auxiliary facilities, etc., occupy a large area and are heavy, and have certain requirements for earthquake resistance and load-bearing capacity of the foundation.

1) Vertical rack traction equipment. The floor space is relatively small, less than 4 m×4 m. There are generally two methods for installing equipment:

(1) The bottom of the equipment should be flush with the workshop floor, and an operating platform for the operator should be constructed. The advantage is that it is easy to install, requires low initial investment in installation costs and is easy to maintain; the disadvantage is that the workpiece must be transported up and down by forklift and other devices to the operating platform. some requirements for the height of the factory building, and it cannot be installed and used in too short a factory.

(2) Dig a pit on the workshop floor and position the control station flush with the workshop floor. The advantage is that it is easy to use and is on the same level as the workshop, which facilitates logistics; the disadvantage is that the initial workload of installing the equipment is significant, including the design and manufacturing of the pit, which must be taken into account. factors such as ground load bearing, equipment maintenance, cleaning and production safety.

Advantages of vertical drawing: It is easy to observe the part when debugging. After removing the protective device in front of the equipment, you can observe the pinout area to prevent the pin from hitting the hard support and being scrapped.

Disadvantages of vertical drawing: After the broaching of the teeth is completed, even if there is a large flow of cutting oil rushing into the broaching area, sometimes there are still iron shavings left in the collet body. When moving to the next cycle, the part is placed in the clamp body. the clamp body and the clamp clamp the workpiece. Imprints are left on the parts, and if you are not careful, the parts will be scrapped in batches.

2) Horizontal rack traction equipment. Usually about 3m × 7m, mainly because the forward and reverse stroke of the spindle is long and requires distance. Advantages of horizontal traction: the equipment is easy to install, the spindle is easy to disassemble, install and adjust, the iron filings are not easy to stay in the clamp body, and the logistics are convenient. Disadvantages of horizontal traction: The equipment takes up a large area. Because the cutting surface is upward, despite the large flow of cutting oil, iron shavings easily remain in the tool’s chip breaker. Excessive residual iron shavings are not conducive to the next one. work cycle.

3) Rack side traction equipment. At present, the main manufacturers of rack broaching equipment are rack broaching machines produced by the Japanese company Nachi Fujikoshi and the German company ArthurKink. Their biggest advantage is that the large flow of cutting oil removes iron filings from the spindle and the clamp body. , and the iron filings flow along the spindle chip breaker and the inner wall of the collet, precipitated from above into the oil tank below, and then discharged.

The connection between wire drawing equipment and automated equipment such as robots or robots with guide rails can realize production automation. The part automatically enters the wire drawing machine from the previous process, and once completed, it automatically enters the next stage (usually removing). burrs at the exit of the teeth). It was used by Shanghai ZF Steering System Co., Ltd. and Shiya Auto Parts (Nantong) Co., Ltd. The initial investment is large, but it can significantly improve equipment utilization efficiency and increase production capacity.

Parts broaching process

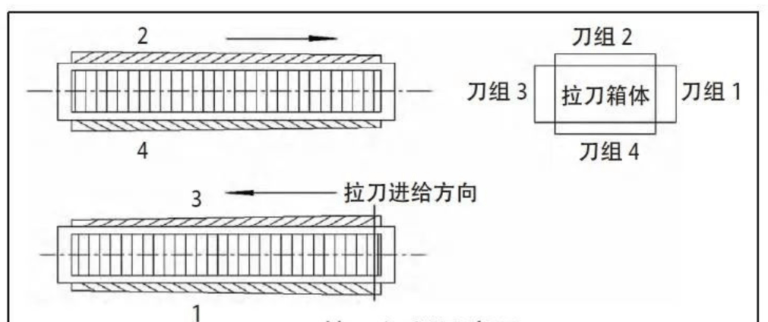

The specific process is as follows: after the workpiece is properly clamped, the pin box first moves to the left, and the first set of pins pulls the teeth. Once the box is in place, the pin box is rotated 90° and secured. and the broach box moves to the right, the second group of broaches on the second side continue broaching the workpiece. Once the box is in place, it is rotated 90° and fixed. The pin box moves to the left for the second time. , and the third set of pins on the third surface The pin group continues to broach the part. Once the box is in place, it is rotated 90° to secure it. The pin box moves a second time to the right. The fourth group of pins on the 4th surface continues to broach the part. Once the box is in place, it is turned again. Fixed at 90°, prepare to broach the next part. The rack in this cycle extracts the complete shape of the tooth. After cutting, the second piece of material is placed. enter the broaching cycle of the next part.

When the pin box moves forward and backward, the pins installed on it all participate in pinout. One broaching stroke is broken down into 4 broaching strokes, making full use of the space and compressing the total length of the equipment to approximately 4 m.

The brooch is a valuable tool. When using the spindle, a tool record and spindle register should be established for each spindle (distinguished according to the part drawing number and the serial number of the tool processed by the spindle) . the person who used the tool each time, the time of use, and the last time the tool was used. The number of cut parts, the cumulative number of broached parts, the number of grinding times, grinding quality, remarks and other conditions of the tool. The spindle and tool card follow the spindle flow, so that relevant personnel can understand the status. of the spindle and ensure the normal use of the spindle and the workpiece. Quality and economic accounting have a certain reference value. Record the spindle inspection report, the report of the first workpiece of the first spindle product, the grinding situation and each spindle accident in detail in the spindle register, and record the contents on the spindle tracking card. tool to prevent tracking from getting stuck on the spindle. Important information lost during the circulation process is specially preserved by the warehouse keeper. The warehouse guard also creates electronic file information for each spindle and records the contents of the tool card and register timely for easy reading and quantity processing. statistics.

Due to the high precision, high price, high hardness and large number of teeth of the spindle, the flat spindle should be placed flat in a wooden box that is easy to carry. There should be no iron filings on the surface of the pin. It must be oiled and rust-proof, and must be stored in a designated location and marked as safe to buff or buff.

Error prevention measures must be taken on the equipment. The pin can only be broached when the rack is correctly positioned and the rack is tightened. The pin can only be returned when the rack is removed from the pinout station.

Spindle grinding is a key process that affects the life of the spindle and the accuracy of subsequent machining of the holder. Before grinding the spindle, make sure the performance of the spindle grinder is intact. If a defect is detected, the relevant personnel must be informed. It’s time to fix it. The operator must be familiar with the various aspects of the crusher. Excellent performance, qualified operation. Before grinding, you should carefully check the wear condition of the grinding spindle (if there is a slight tooth breakage or significant wear, mark it with a marker, and after grinding, focus on checking whether it has been ground cleanly), and check the reference plane of the tool and the magnetic plane of the machine tool. Check for dents on the side reference. If you find any, remove them with a sharpening stone. The spindle can be ground without leaving any space between the spindle side and the grinder positioning reference. Usually the spindle is only allowed to grind the cutting angle. The side grinding speed and feed amount should be as low as possible. cooling should be sufficient to reduce the roughness of the grinding degree and does not change the original physical properties of the tool.

Production companies such as Zhejiang Change, consultation hotline: 15910974236

When grinding the clearance angle, since the tooth lift of each knife is different, be sure to read the diagram carefully and grind according to the original lift. When grinding, measure with a dial indicator first to confirm the difference between the replacement teeth to be used. Grinding can only be continued after meeting the requirements of the drawing. After grinding, clean the spindle, inspect it, apply oil to prevent rust, complete the spindle tracking card if necessary, and return the spindle to the warehouse.

Proper management and sharpening of flat pins can significantly extend the life of pins, ensure stable quality of processed products, and fully realize the advantages of broaching. This management mode can also be used for the daily management of other spindles or hobs.

In order to improve the working efficiency of the broaching machine, it is recommended to replace the spindle and the spindle holder at the same time when replacing the spindle. Install the ground spindle and spindle holder onto the equipment as a whole. positioned quickly using pins or positioning blocks. The tool holder is quickly hydraulically tightened, and the quick changeover time is about 1 hour. The spindle is ground on the spindle seat on the grinding machine as a whole, which eliminates the tooth shape error caused by secondary clamping of each spindle blade and each section of the spindle. After grinding, the spindle and spindle seat marks are retained as they are. a whole. The above model was used by Shanghai ZF Steering System Co., Ltd., which greatly improved the effective working time of the gear traction machine.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.