Ability to produce more complex shapes

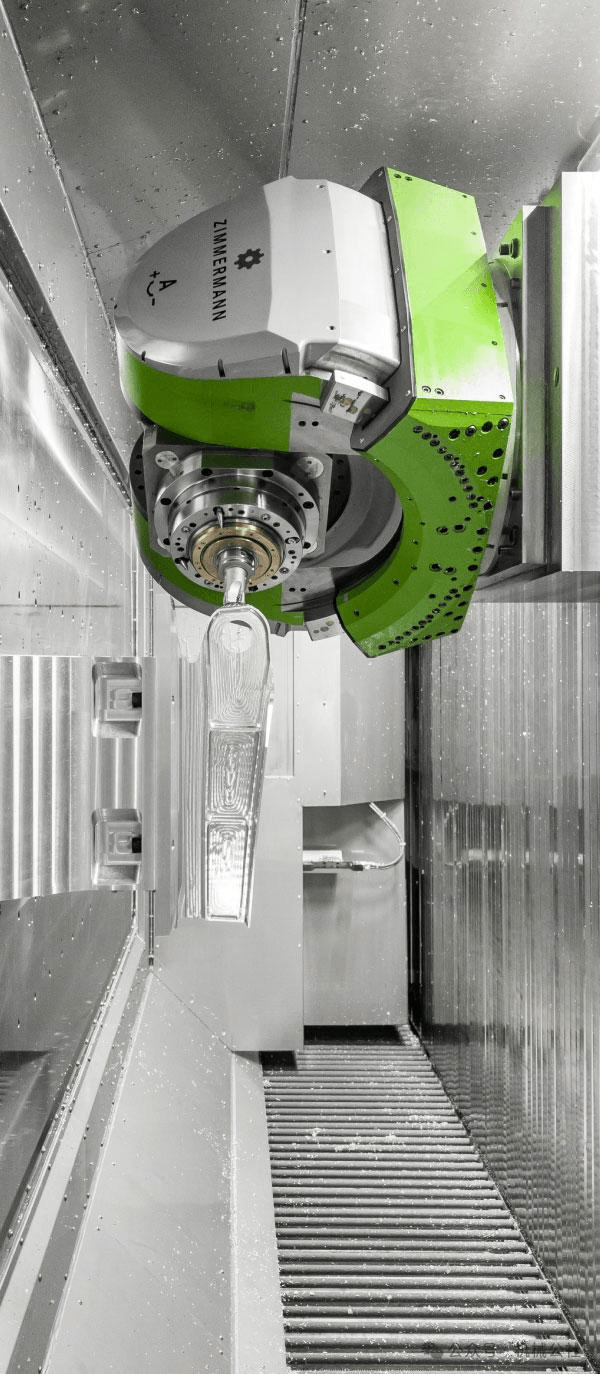

The greatest advantage of 5-axis machining is the ability to machine complex shapes and parts from solid bodies that would otherwise have to be cast. This additional movement creates machining angles and arcs that were previously only possible with a multitude of special fixtures or additional configurations. It can offer turnaround times of one to two weeks instead of the two months or more required for castings.

Reduce rearrangements

5-axis machines can machine almost any visible surface, reducing the need for multiple setups or special features. Thanks to the range of motion of their cutting heads and the additional axis of rotation, these machines can reach 5 sides of the workpiece, which means less readjustments and adjustments. This not only saves time, but also costs and operator errors. Additionally, in many configurations, there is always the possibility of incorrect alignment every time a part is moved.

Reduce labor costs per part

Every time a machine operator touches a part, additional costs are incurred. By choosing a 5-axis machine, this wasted time and associated costs can be eliminated. This also reduces labor costs by reducing the time required to reattach parts. The shorter the time an operator needs to be in contact with a part, the lower the cost.

3+2 axis machining

Some parts can only be machined with 5-axis motion, however, other parts can be machined more efficiently with 3+2 motion. Here the 4th and 5th axes are used to hold the part in a fixed position, so there is no need to move all 5 axes at the same time. 3+2 machining is ideal for parts with multiple faces or angular features.

Better surface finish

Using 5-axis capabilities on contour geometry directly results in better overall surface finish in less time compared to 3-axis machining, where good surface finish requires longer lead times. Using shorter tools in 5-axis machining reduces tool vibration, resulting in a higher quality surface finish. This reduces, if not completely eliminates, the need for tedious manual finishing.

Accuracy between features

Once the part is removed from the machine, inaccuracies may occur with each setting change and precise alignment may be lost. Using the same “zero” or “home” position means maintaining accuracy from one feature to the next.

Faster cutting speed

With shorter tools, 5-axis machines are able to get closer to the material, allowing higher cutting speeds without imposing excessive loads on the tool. This not only extends tool life, but also reduces tool vibration and breakage. The machine also has an additional axis of rotation: drilling compound holes at odd angles is much faster than with traditional CNC machines because the head can automatically orient itself along the correct axis for each hole .

Increase opportunities in key markets

5-axis CNC machines maximize productivity by reducing cycle times when manufacturing complex parts such as turbine blades, wheels and aerospace aircraft airframes. As a result, this efficiency allows manufacturers to successfully compete in aerospace, automotive, medical and other major industries.

Improve floor space utilization

By adding a 5-axis machine, many other machine tools can be eliminated or reused, increasing the space available in the workshop. These reused lathes, VMCs or HMCs can then be used to produce less complex parts, making them more cost effective.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.