1. Methods to prevent and reduce welding distortion should consider the design of the welding process and overcome the changes of hot and cold cycles during welding. Shrinkage cannot be eliminated, but it can be controlled. Ways to reduce shrinkage deformation are as follows.

1. Don’t oversolder

The more metal there is at the welding point, the greater the deformation force will be. Correct sizing of the weld bead not only achieves lower welding deformation, but also saves welding time and materials. The amount of molten metal filling the weld should be minimal, the weld should be flat or slightly convex, and excess molten metal will not increase strength. On the contrary, it will increase the shrinkage force and increase the welding deformation.

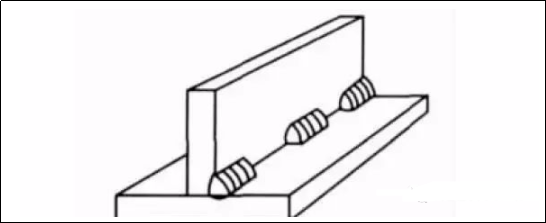

2. Intermittent welds

Another way to reduce the amount of weld filler is to use more interrupted welding. For example, when welding reinforcement plates, intermittent welding can reduce the amount of weld filler by 75% while ensuring the required strength.

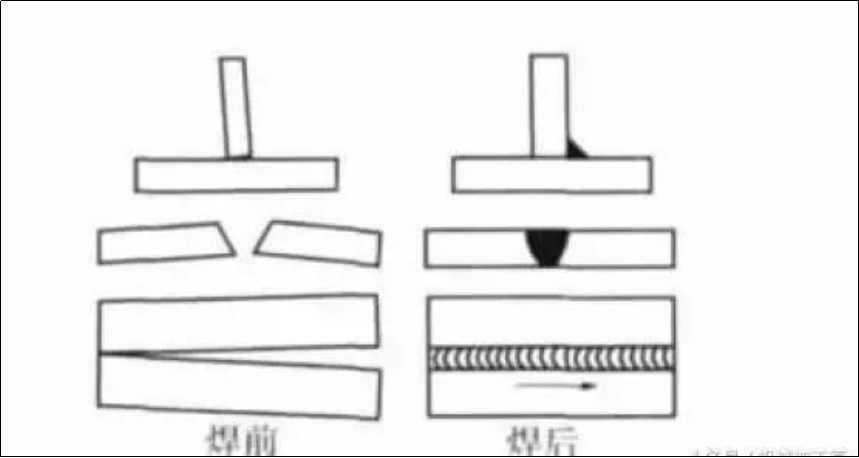

3. Reduce weld seams

Welding with thick welding wire and few welding passes will have less deformation than welding with thin welding wire and many welding passes. When there are multiple weld passes, the shrinkage caused by each weld pass cumulatively increases the total weld shrinkage. It can be seen from the figure that the welding process with few welding passes and thick electrodes gives better results than the welding process with many welding passes and thin electrodes.

Note: The welding process of thick welding wire, few welding passes or thin welding wire, multiple welding passes depends on the material. Generally, low carbon steel, 16Mn and other materials are suitable for thick welding wire and few welding passes, while stainless steel. , high carbon steel and other materials are suitable for fine welding, multi-pass welding.

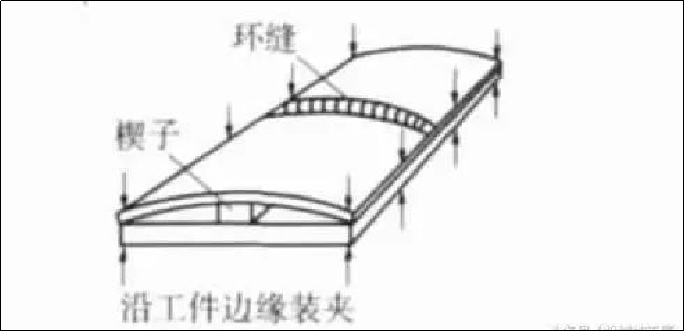

4. Anti-deformation technology

Before welding, parts should be bent or tilted in the direction opposite to the welding deformation (except for overhead welding or vertical welding). The preset amount of anti-deformation should be determined by testing. Pre-bending, pre-adjusting or pre-bending welded parts is a simple way to counteract welding stresses by neutralizing mechanical forces. When the part is preset, deformation occurs that causes the part to resist the shrinkage stress of the weld. The deformation before welding and the deformation after welding cancel each other out, making the part to be welded an ideal plane.

Another common method for balancing shrinkage forces is to place identical weldments opposite each other and clamp them. This method can also be used for pre-bending, where the shim is placed in the appropriate position on the part before clamping.

High-strength special welding parts can generate the required balancing force due to their own rigidity or the mutual position of the parts. If these balancing forces are not generated, other methods must be used to balance the shrinkage force of the weld material to be compensated. each other. The balancing force may consist of other shrinkage forces, mechanical stresses formed by tooling devices, stresses formed by the sequence of assembly and welding of components, and stresses formed by gravity.

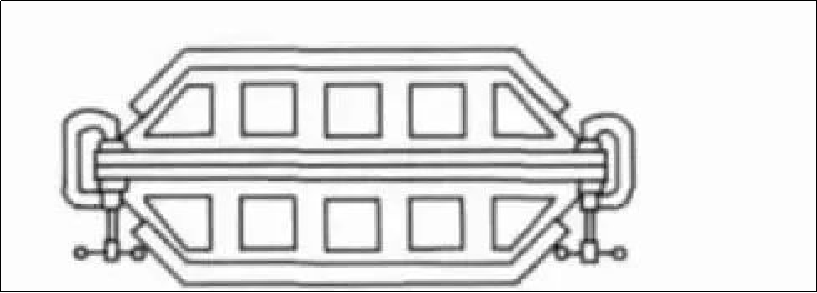

5. Welding sequence

Determine a reasonable assembly sequence according to the structural shape of the part so that the structure of the part retracts to the same position. Make double-sided grooves in the center and axis of the workpiece, use multi-layer welding, and determine the double-sided welding sequence. Intermittent welding is used in fillet welds, and the shrinkage of the first pass is balanced by the shrinkage of the second pass. Tooling fixture can fix the workpiece in the required position, increase rigidity and reduce welding deformation. This method is widely used for soldering small parts or components. Due to the increased welding stress, it is only suitable for steel structures with low carbon content and good plasticity.

6. Remove shrinkage force after welding

Tapping is a method of counteracting solder shrinkage forces as the solder cools. Tapping will cause the weld to expand and thin, thereby relieving stress (elastic deformation). However, when using this method, care must be taken not to tap the root of the weld, as cracking may occur during tapping. In general, tapping cannot be used on cap welds either.

Because the cover layer may have weld cracks, which will affect the weld detection and produce a hardening effect. Therefore, the use of the technology is limited, and there are even cases where it is necessary to tap only inside the multi-layer weld bead (except bottom welding and cover welding) when tapping the weld bead to solve the problem of deformation or cracks. Heat treatment is also one of the methods to eliminate the shrinkage force by controlling the high temperature and cooling of the workpiece; Sometimes the same part is clamped and welded back to back, and this alignment condition is used to eliminate stress and minimize residual stress of the workpiece.

6. Reduce welding time

Heating and cooling occur during welding, and heat transfer also takes time. Therefore, the time factor also affects the deformation. Usually you want the welding to be completed as quickly as possible before the large part expands from the heat. The welding process, such as the type and size of the welding rod, welding current, welding speed, etc., affect the degree of shrinkage and deformation of the welded workpiece. The use of mechanized welding equipment reduces welding time and the amount of heat distortion.

2. Other methods to reduce welding distortion

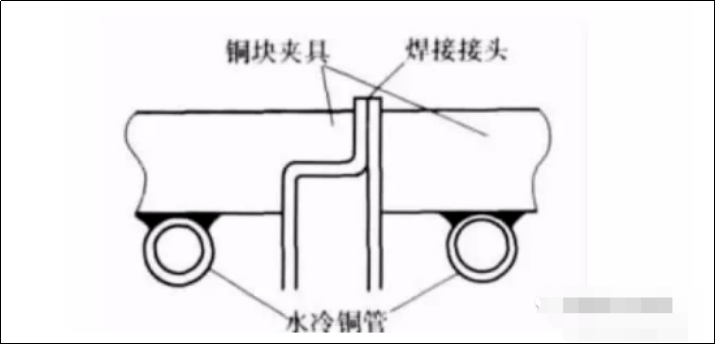

1. Water cooling block

Many techniques are available to control welding deformation of special welding parts. For example, in thin plate welding, a water cooling block can be used to remove heat from the workpiece. The copper pipe is soldered to the copper fixture by brazing or brazing, then circulated and cooled in the water pipes to reduce distortion due to soldering.

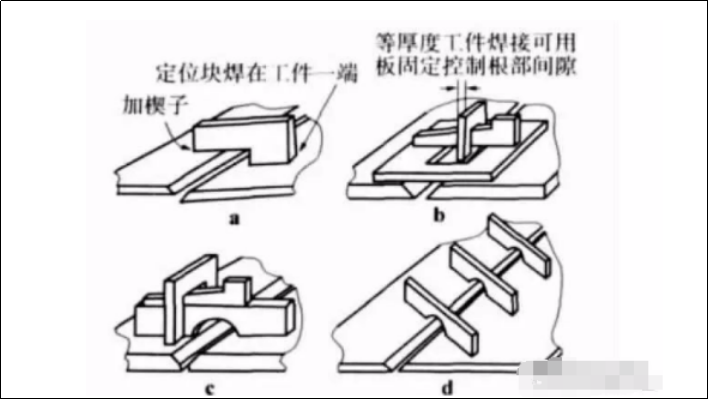

2. Corner block positioning plate

“Positioning plate” is an effective technology to control welding deformation during butt welding of steel plates, as shown in the figure. One end of the locating plate is welded to a plate of the workpiece and the other end wedges the corner block into the pressure plate. Multiple positioning plates can even be arranged to maintain the positioning and fixation of the welded steel plate during welding.

3. Eliminate heat stress

Unless there are special circumstances, using heating to relieve stress is not the right method. Weld deformation should be avoided or reduced before welding the part.

3. Conclusion

To reduce the effects of welding deformation and residual stress, the following points should be considered when designing and welding parts:

(1) Do not carry out excessive welding; (2) Check the positioning of the workpiece; (3) Use intermittent welding as much as possible, but it must meet the design requirements; (4) Use as small a welding leg size as possible; (5) For sloped openings For welding, the amount of joint welding should be minimized, and double-sided grooves should be considered to replace single-sided groove joints. (6) Multi-layer multi-pass welding shall be used as; as much as possible instead of single-layer double-sided alternating welding. Perform double-sided groove welding in the workpiece and on the axis, use multi-layer welding, and determine the double-sided welding sequence; (7) Use multi-layer welding with fewer weld passes (8) Use low heat input welding; technology, which means higher deposition rate and faster welding speed; (9) Use a positioner to place the workpiece in the boat welding position; Large diameter welding wires and high deposition rate welding processes can be used for boat welding position; (10) Set the weld to the neutral axis of the workpiece as much as possible and weld symmetrically; (11) Try using the welding sequence; and welding positioning as much as possible Ensure that the welding heat spreads evenly; (12) Weld in the unconstrained direction of the workpiece; (13) Use fasteners, tools and positioning plates for adjustment and positioning. (14) Pre-bend the part or predefined weld joint in the opposite direction of shrinkage. (15) Partial welding and full welding in sequence can keep the welding balanced around the neutral axis.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.