Tool vibration is a common problem during machining. They not only have a negative impact on machining accuracy and surface quality, but also shorten tool life. Let me explain in detail what causes tool vibration and how to fix it:

1. Reasons

1. Incorrect setting of cutting parameters

cutting speed

Too high: Too high a cutting speed will result in unstable cutting force and cause tool vibration.

Too low: Too low a cutting speed will increase friction between the tool and workpiece, resulting in vibration.

Amount of food

Excessive: Excessive feed will increase cutting force and cause tool and workpiece vibration.

Too low: The feed quantity is too low, which will make the cutting process unstable and produce vibration.

cutting depth

Too Deep: Excessive cutting depth will increase the load on the tool and cause vibration.

2.Tool geometric parameters

front and back corners

The cutting angle is too small or too large: an incorrect cutting angle will make chip evacuation difficult and cause vibration.

The clearance angle is too small: A clearance angle that is too small will increase friction between the tool and the workpiece surface, resulting in vibration.

Edge radius

Too large or too small: Improper cutting radius will affect the cutting force distribution and cause vibration.

3. Insufficient tool rigidity

Tool materials and construction

Material Strength: Insufficient strength and rigidity of the tool material can cause vibration.

Tool overhang: Too long an overhang will reduce rigidity and increase the risk of vibration.

Tool clamping

Not properly tightened: Tools that are not properly tightened can cause vibration.

Clamping position: Improper tool clamping position can reduce stability and cause vibration.

4. Clamping and supporting the workpiece

clamping force

Too big or too small: Improper clamping force of the part will cause the part to deform or loosen, causing vibration.

fulcrum

Unstable: Unstable or poorly positioned part supports increase the risk of vibration.

5. Rigidity and precision of machine tools

Machine tool structure

Rigidity of the machine tool: Insufficient rigidity of the machine tool itself can cause vibrations.

Guide rail accuracy: The accuracy and lubrication condition of the guide rails of the machine tool will affect the vibration.

Maintenance of machine tools

Looseness and wear: Looseness or wear of machine tool components will reduce processing stability and generate vibration.

6. Cutting fluid and lubrication

Cutting fluid supply

Insufficient: Insufficient supply of cutting fluid will cause an increase in cutting temperature and increased vibration.

Unsuitable: Improper type of cutting fluid will affect the lubrication effect and cause vibration.

7. Environmental factors

temperature change

Thermal expansion: Temperature changes will cause thermal expansion of the tool and workpiece, affecting the cutting process and causing vibration.

mechanical vibrations

External interference: Vibrations caused by external equipment or mechanical operations will be transmitted to the machine tool, affecting the processing stability.

2. Solutions

1. Optimize cutting parameters

cutting speed

Adjust speed: Adjust the cutting speed to the optimal range depending on the material and processing conditions. The optimal cutting speed can usually be found through experiments.

Amount of food

Optimize the amount of food: In order to ensure the effectiveness of the treatment, adjust the amount of food appropriately to avoid too much or too little amount of food.

Gradual adjustment: Gradually adjust the feeding amount to find the most stable treatment state.

cutting depth

Step-by-step cutting: For greater cutting depths, use step-by-step cutting to gradually remove material and reduce tool load.

2. Optimize cutting parameters

front and back corners

Adjust the angle: According to the processing materials and requirements, appropriately adjust the front and rear angles to improve chip evacuation and reduce friction.

Use custom tools: For special materials or machining conditions, consider using custom tools to optimize cutting performance.

Edge radius

Optimize edge radius: Choose an appropriate edge radius to ensure even distribution of cutting forces and reduce vibration.

3. Improve workpiece clamping and support

clamping force

Proper Tightening: Make sure the workpiece is securely clamped, but do not overtighten to avoid distortion of the workpiece.

Even clamping: Use multiple clamps or evenly distributed clamping force to ensure workpiece stability.

fulcrum

Increase support: For long or thin parts, add support points to prevent the part from vibrating during processing.

Use a heel block: Use a heel block if necessary to provide additional support and stability.

4. Improve the rigidity and precision of machine tools

Machine tool structure

Choose high-rigidity machine tools: Use machine tools with higher structural rigidity to reduce vibration caused by insufficient machine tool rigidity.

Optimize machine tool layout: Ensure machine tools are installed on a stable, level foundation to reduce the impact of external vibrations.

Maintenance of machine tools

Regular inspection: Regularly inspect all parts of the machine tool, especially key parts such as guide rails and screws, to ensure that there is no play or wear.

Lubrication maintenance: keep the lubrication system of the machine tool in good condition, reduce friction and wear, and improve processing stability.

5. Optimize cutting fluid supply

Type of cutting fluid

Choose the appropriate cutting fluid: According to the processing materials and process requirements, select the appropriate cutting fluid type to improve the lubrication and cooling effects.

Cutting fluid supply

Ensure Adequate Supply: Ensure adequate supply of cutting fluid, especially when cutting at high speeds and machining deep holes. High pressure coolant facilitates chip removal and cooling.

Adjust the cutting fluid flow: Depending on the cutting conditions, appropriately adjust the cutting fluid flow to ensure that the cutting area is fully cooled and lubricated.

6. Control environmental factors

temperature control

Stable ambient temperature: Keeps the processing environment temperature stable and reduces dimensional changes and vibration caused by thermal expansion.

Use cooling devices: Use air conditioning or cooling devices when necessary to control the temperature of the workshop.

Reduce external interference

Isolate vibration sources: Isolate the machine tool from other sources of vibration, for example by using shock absorber pads or basic vibration absorption installations.

Reduce operational interference: During the processing process, avoid direct operator interference on the machine tool.

By comprehensively considering and optimizing all the above aspects, tool vibration can be effectively reduced, machining accuracy and workpiece surface quality can be improved, and the service life of the tool can be extended.

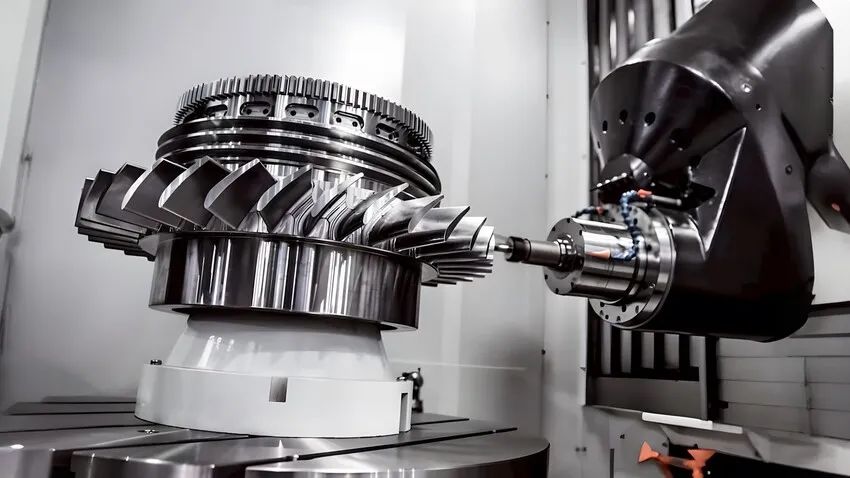

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.