As market requirements for imaging quality and device miniaturization continue to increase, high-precision aspherical optical mirrors have gradually found important applications in optical instruments, space laser communications, aerospace and other areas. As a new generation of optical processing technology, magnetorheological polishing technology has the characteristics of stable removal function, high material removal efficiency, controllable processing process, high surface precision after polishing and is suitable for complex surface processing. It is of great importance in aspherical surfaces. treatment. However, due to the strict confidentiality of key technologies of magnetorheological polishing abroad, especially the development of magnetorheological polishing fluids, the application of our country’s magnetorheological polishing technology in practical projects has been limited.

Source: Zhongke Qingbang Technology Co., Ltd.

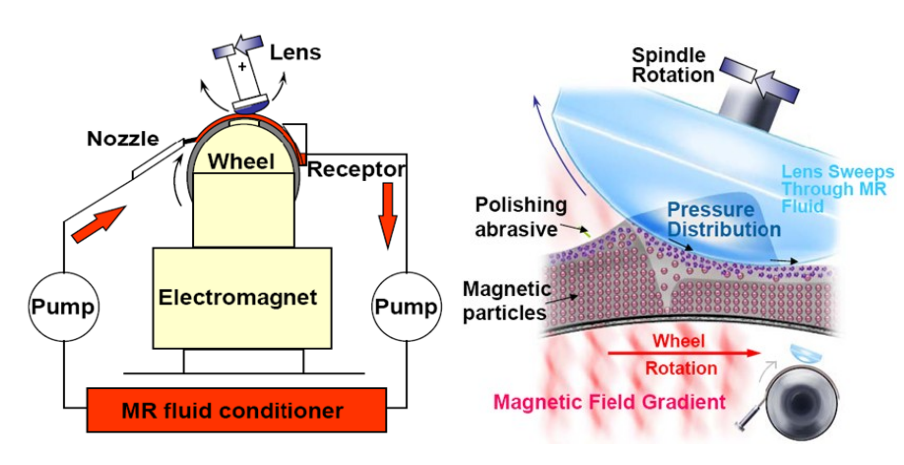

Principles of magnetic fluid polishing technology

The key to precision machining in magnetorheological polishing lies in the magnetorheological fluid. When there is no external magnetic field, the magnetorheological fluid is in a fluid state and the ferromagnetic particles are randomly dispersed in the system. However, when an external magnetic field is applied, the magnetic particles flow rheologically in the direction of the magnetic field. field under the action of the magnetic field to form a viscous structure. During polishing, the “flexible polishing mold” formed by the magnetorheological fluid forms a shear force in the area contacting the workpiece by adjusting the rotation angle and speed of the. Workpiece, the surface material of the workpiece can be oriented in all directions. Remove evenly and obtain a smooth surface.

Principle of magnetorheological polishing (Source: Reference 1)

Performance requirements of magnetorheological polishing fluid

As a key consumable for magnetorheological polishing, magnetorheological polishing fluid must not only have the basic properties of traditional magnetorheological fluids, but also meet certain performance requirements that can meet precision polishing, such as low viscosity zero magnetic field, good anti-sedimentation stability and ease of use. Redispersion, high shear yield strength, fast dynamic response, wide working range, environmental protection, etc. In the preparation process of magnetorheological polishing fluid, the selected added ingredients should fully take into account these indicators to achieve excellent polishing effects.

In addition to the components contained in typical magnetorheological fluids such as continuous phase base carrier fluid, dispersed phase ferromagnetic particles and stabilizers, magnetorheological polishing fluids also add polishing powder to improve polishing efficiency .

01

carrier fluid

The basic carrier fluid of magnetorheological polishing fluid is mainly divided into two categories: water-based and oil-based.

Water-based magnetorheological polishing fluid generally uses deionized water as the base carrier fluid. Optical glass is polished using it, which is beneficial to the polishing process and increases the polishing rate. It also has a low zero magnetic field. viscosity and is easy to clean after polishing. However, the water-based carrier fluid is easily evaporated during the polishing process, which has a great impact on the composition of the magnetorheological fluid. It is necessary to regularly add a base carrier fluid to ensure the stability of the composition. At the same time, water-based magnetorheological polishing fluid also has poor dispersion stability and corrosion resistance. The failure of improper oxidation can easily lead to a significant decrease or even failure in the operating efficiency of magnetorheological devices.

Oil-based magnetorheological fluid is a type of polishing fluid developed for water-soluble materials such as KDP crystals, mineral oil, synthetic hydrocarbons, glycerin, etc., which are generally used as the basic carrier fluid. Crystals, compared with water-based magnetorheological polishing fluid, also have the advantages of good dispersion stability and good anti-corrosion properties. However, due to the high viscosity of zero magnetic field, it will be difficult to clean the polished workpiece and cause contamination of the workpiece. surface of the polished part.

02

magnetic particles

The rheological effect of magnetorheological fluid is due to the magnetic particles forming magnetic dipoles under the action of the magnetic field, which interact to form a chain or column structure, thus becoming a quasi-solid state. is one of the main factors affecting the yield strength before magnetorheology. At present, carbonyl iron powder has become one of the most commonly used magnetic particle materials in magnetorheological polishing fluids due to its series of unique properties:

(1) The saturation magnetic induction intensity of carbonyl iron powder can reach 2.2T, which can ensure that the magnetorheological fluid has high shear yield strength.

(2) The minimum magnetic coercivity can reach 0.05 Oersted, which ensures that the viscosity of the magnetorheological fluid can quickly return to the zero magnetic field viscosity state after the magnetic field is removed, thereby ensuring that the liquid can be recycled stably during the polishing process. .

(3) It has moderate hardness and a unique onion ball layered structure, which will not cause damage to the surface of optical parts during polishing.

(4) The magnetization properties of carbonyl iron powder are less affected by temperature, and the magnetorheological fluid can maintain stable performance under different temperature conditions.

(5) Carbonyl iron powder has high magnetic permeability, allowing the magnetorheological fluid to show good response performance under weaker magnetic fields.

(6) The hysteresis loop is narrow and the cohesion is weak, which can reduce the energy loss of magnetorheological fluid rheology;

Carbonyl iron powder (source: Internet)

03

polishing powder

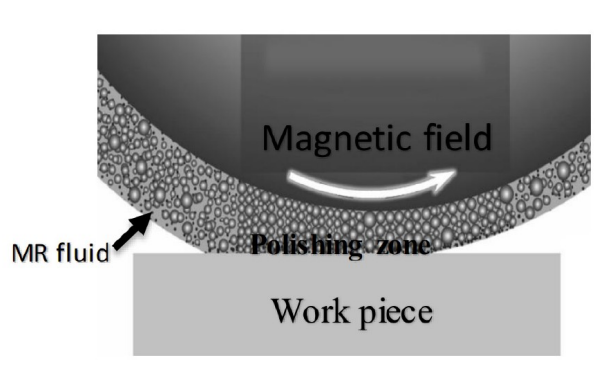

During the magnetorheological polishing process, the magnetorheological polishing fluid passes through the polishing zone. Under the action of the magnetic field, the magnetorheological fluid forms a flexible polishing head, and the polishing powder exudes polishing fluid and directly acts on the optical glass. On the surface, under the action of the shear force caused by the rotation of the flexible polishing head, the material on the surface of the workpiece is removed. The choice of polishing powder has a significant impact on the shearing effect during processing.

The higher the hardness of the polishing powder, the higher the polishing efficiency. Currently, commonly used polishing powders in descending order of hardness include: diamond powder, alumina, cerium oxide, etc. Diamond powder is often used to polish materials with higher hardness. Like silicon carbide, the cost of alumina is relatively low, and it is often used in the fields of large sapphire single crystals, laser crystals, optical fiber interfaces and other optical crystals, while the Cerium oxide can undergo condensation reaction with silicon dioxide surface to increase the polishing rate and is the most suitable polishing glass material.

Schematic diagram of the magnetorheological polishing zone (Source: Reference 1)

In addition, the particle size of the polishing powder also has a certain impact on the polishing effect. Under the influence of a magnetic field, abrasive grains are mixed between carbonyl iron powder (CIP) arranged in a chain structure. When the size of abrasive grains mixed in the CIP magnetic chain is larger, the deformation of the CIP magnetic chain will be. the more serious, and the bonding force will be reduced the weaker it is, the weaker the magnetic interaction. When the particle size difference between CIP and abrasive is small, the force interaction is greater and the polishing efficiency is higher.

04

dispersion stabilizer

Since the density of ferromagnetic particles in the magnetorheological fluid is much higher than that of the base carrier fluid, the magnetorheological fluid is prone to sedimentation over time. Usually, these particles condense to form agglomerates that are difficult to redisperse. the performance of the magnetorheological fluid and even causes the failure of the magnetorheological fluid, finally affecting the magnetorheological polishing effect. In order to maintain the stability of the magnetorheological polishing fluid, it is often necessary to add a dispersion stabilizer.

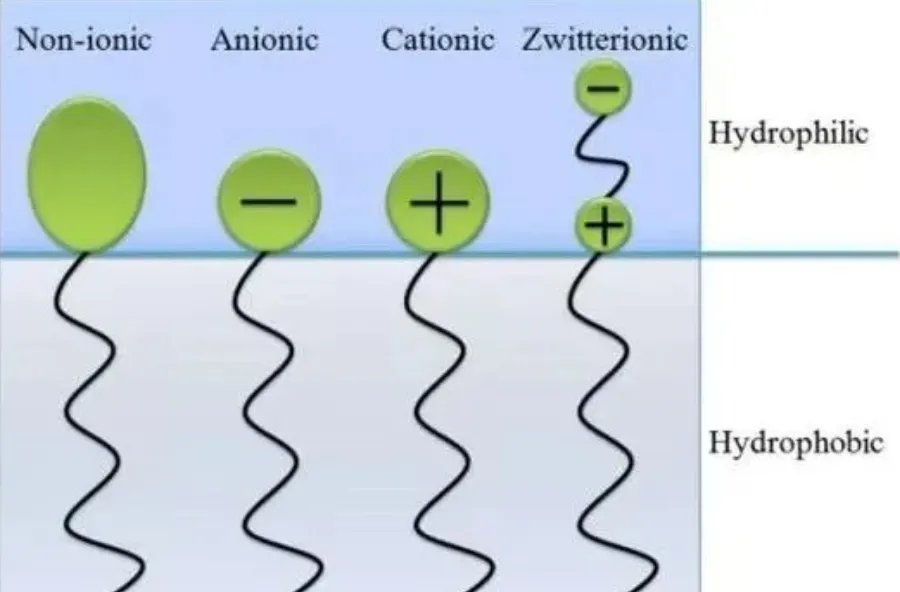

Dispersion stabilizers can be roughly divided into four types: anionic, cationic, zwitterionic and nonionic. The selection depends on many factors such as the characteristics of the material to be dispersed and the properties of the dispersion medium. For example, magnetorheological fluids containing carbonyl iron powder often use anionic dispersants containing -COOH groups. -COOH groups can interact in solids through ionic bonds, covalent bonds, hydrogen bonds, and Van der Waals forces. particles, which gives rise to a stable dispersion system.

Four dispersion stabilizing structures

Additionally, the molecular weight of the dispersant will also have a greater impact on the viscosity and dispersion characteristics of the dispersion system. If the molecular weight is too small, it will not be able to provide sufficient spatial repulsion for the iron powder particles. which is detrimental to the stability of the magnetorheological fluid system. The assembly will cause flocculation through the entanglement between the hydrophobic chains, which will make the initial viscosity of the magnetorheological fluid too large, prone to flocculation, and affect the rheology of the magnetorheological fluid. fluid.

05

Other additives

In addition to the dispersion stabilizer, a wetting agent is often added to the magnetorheological polishing fluid depending on the situation to improve the wettability of magnetic particles in the polishing fluid; a PH regulator is added to ensure that the dispersion stabilizer exerts the best effect; , and ensure the anti-rust capacity of the magnetorheological fluid…..

summary

Magnetorheological polishing fluid is one of the key technologies of magnetorheological polishing. The performance of magnetorheological polishing fluid determines the efficiency of magnetorheological polishing and the surface quality of the polished workpiece. At present, the preparation technology of magnetorheological polishing fluid in my country is still limited by others. It is necessary to further study the dispersion mechanism of magnetorheological polishing fluid and combine the actual processing needs with a reasonable combination of various components to optimize the dispersion. stability of magnetorheological polishing fluid, magnetic properties, rheological properties, etc.

References:

1. Bai Yang. Development of a magnetorheological polishing fluid and study of the stability of the elimination function.[D].Graduate School of Chinese Academy of Sciences (Changchun Institute of Optics, Precision Mechanics and Physics).

2.Dong Huiwen. Research on waterless magnetorheological polishing fluid and polishing process.[D].Xi’an University of Technology.

3. Dai Lida, Zhang Zhengyan, Qiao Guochao Research progress of magnetorheological polishing technology.[J].Mechanical design and manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.