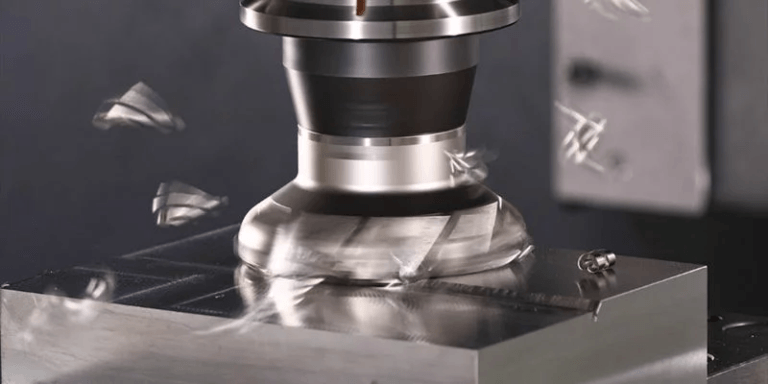

Milling is a machining process in which the blank is clamped and the high-speed rotary cutter moves along the blank to cut out the required shapes and features. Traditional milling is primarily used to machine simple shapes/features such as contours and slots. It removes material from the workpiece through the rotational motion of the cutter and the feed motion of the workpiece to form the required geometry and surface quality. Milling can process a variety of complex shapes such as planes, grooves, gears, threads and curved surfaces.

Every step and consideration in milling helps ensure machining quality, tool life and overall efficiency. This issue summarizes 17 detailed milling processing points for you:

1.Power

Check the power and rigidity of the machine: It is important to ensure that the machine tool has sufficient power and structural rigidity to mill with the required cutter diameter.

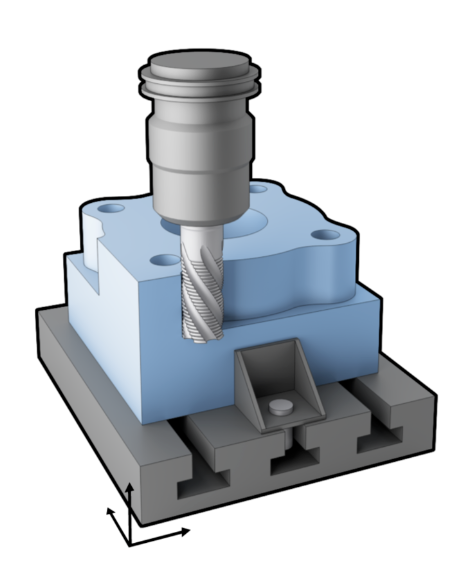

2. Stability of the part

Part Clamping Conditions and Considerations: It is important to ensure that the part is securely clamped to prevent it from moving or vibrating during machining to maintain machining accuracy.

3. Mitsunobu

Reduce tool overhang: During milling, the length of the tool overhang on the spindle should be shortened as much as possible to improve tool rigidity and reduce the probability of vibration and tool offset.

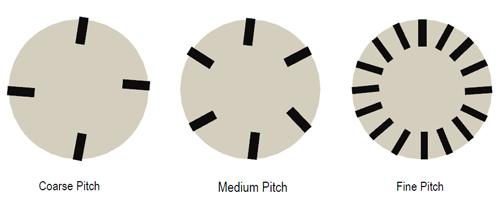

4. Choose the right cutter pitch

Cutter pitch selection: During the processing process, it is necessary to select an appropriate milling cutter pitch according to the specific process requirements to ensure an appropriate number of blades participating in cutting and avoid vibration caused by too many of blades.

5. Carving knife

Make sure the blade has sufficient engagement: When milling narrow workpieces or spaces, it is necessary to ensure that the blade has sufficient engagement to ensure a stable cutting process.

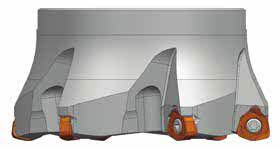

6. Insert a geometry selection

Use inserts with positive rake angle geometry: In actual machining, indexable inserts with positive rake angle geometry should be preferred, which can ensure smooth cutting results and lower power consumption the weakest.

7. Use the right food

Choose the correct feed: In milling, it is necessary to choose the appropriate recommended maximum chip thickness according to the type of insert used to ensure the correct feed and achieve the best cutting effect.

8. Cutting direction

Prioritize down milling: During the milling process, give priority to down milling, which can reduce cutting force, improve surface quality and extend tool life.

9. Parts Considerations

Workpiece material and configuration: Before milling, it is necessary to reasonably select the processing parameters and tool configuration according to the material properties and surface quality requirements of the workpiece.

10. Selection of blade material

Select the appropriate blade material: When selecting the blade, you should select the appropriate geometry and blade material according to the material type and specific application of the workpiece to improve processing efficiency and tool life.

11. Vibration-absorbing cutter

Use anti-vibration tools: In milling operations with long overhangs (more than 4 times the tool diameter), the use of anti-vibration tools can significantly improve the productivity and stability of the process.

12. Main declination angle

Select the appropriate attack angle: When milling processing, according to the specific processing needs, select the most appropriate attack angle to optimize the cutting force and surface quality.

13. Cutter diameter

Choose the right cutter diameter: In order to ensure the best cutting effect and processing efficiency, it is necessary to select the appropriate cutter diameter according to the width of the workpiece.

14. Cutter position

Position the cutter correctly: When machining with a cutter, it is important to ensure that the cutter is correctly positioned relative to the workpiece to avoid unnecessary tool wear and damage to the workpiece.

15. Milling cutter cutting in and out

Optimized entry and exit paths: The arc entry method can keep the chip thickness at zero when retracting the tool, thereby increasing the feed speed and extending the tool life. tool.

16. Coolant

Use coolant timely: The usage of coolant should be determined based on the specific situation. Normally, milling operations are best performed without using coolant, but under high temperature and pressure conditions, using a coolant can help protect the tool and workpiece.

17.Maintenance

Follow tool maintenance recommendations: To ensure optimal performance and machining quality of your tools, check tools regularly for wear, maintain them and replace them as recommended.

To summarize

By strictly following the above milling processing points, the efficiency and stability of the entire processing process can be ensured, thereby improving the surface quality and dimensional accuracy of the workpiece and greatly extending the service life. tool life. In the actual treatment process, these points should be applied flexibly according to the specific situation, and the treatment parameters should be adjusted accordingly to achieve the best treatment effect.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.