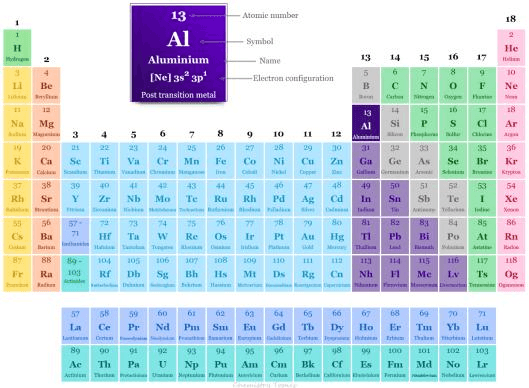

Modern industry requires that parts processing be carried out efficiently. Customers want orders fulfilled faster and demand consistent quality parts. Aluminum is one of the most commonly used alloys in modern production and appears to be the best material. It is light, strong, durable and corrosion resistant. This is why new aluminum crushing strategies are rapidly developing.

One of the modern and successful methods of CNC aluminum milling is called high-speed machining. The main difference from traditional milling is that high-speed milling operates at much higher speeds, allowing operators to increase cutting feeds. Therefore, milling aluminum with HSM is very advantageous in many unexpected ways. Here are the benefits you’ll get by choosing an HSM strategy for aluminum instead of using traditional milling.

1. More efficient

By increasing the cutting speed up to 3 times that of traditional aluminum milling, the feed rate can be increased up to 2 times (for softer aluminum alloys). To our knowledge, machining feed rate is the parameter that defines the productivity of the entire milling process. That said, the efficiency of high-speed machining is comparable to that of traditional milling. The machinability of aluminum allows spindle speeds to be increased to 18,000 rpm or more, resulting in horrendous material removal rates.

Such material removal rates make aluminum machining services using HSM strategies a very cost-effective option for the automotive and aerospace industries. In the first case, automotive prototypes require significant material removal and it is preferable to have as few milling setups as possible. In the second case, there are many long and large parts, they have deep recesses (they have to be light, so they are mainly machined as a set of intersecting ribs) and thin walls, in addition the planes and The rockets are made from 80% aluminum alloy.

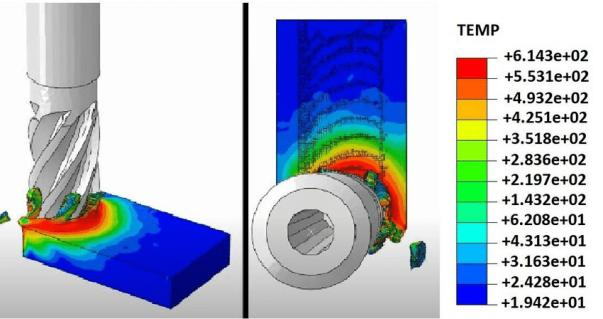

2. Cutting temperature

It turns out that the cutting temperature changes with increasing speed. Initially, as the speed increases, the temperature also increases. However, as speed increases, the temperature begins to drop significantly, until at a certain point, temperature no longer matters. Increasing the cutting speed will only slightly reduce the temperature. This transformation is the hallmark of HSM. For example, when milling aluminum at a speed of 300-500 m/min, the temperature can reach 600-800 degrees. However, if we increase the speed to 1200°C, the temperature drops to less than 200 degrees, while when milling at 1800 m/min, the temperature is only 150°C. From this point on, faster cutting speeds no longer make sense.

Think about it, at only 150-200 degrees due to localized heat treatment, there is no change in material properties in the cutting zone, no increase in metal particles and the need for cooling is much more weak. I think it’s a good advantage.

3. Longer tool life

This may seem strange, since the cutting speed is faster, the tool wear must also be greater, but if we compare the amount of material removed by the aluminum cutting tool in HSM and in conventional milling, rather than tool life (in minutes), we You will find that the difference is obvious and that high-speed milling of aluminum is superior. What is the reason for the extended tool life? First, cutting temperatures are lower, which means the tool material is stronger. Then the chip width during high-speed milling is much smaller (the tool rotates faster, cutting thinner chips even at higher feed rates).

Additionally, one of the main problems when machining aluminum is that it is too soft and sticks to the tool edge during machining. This reduces tool sharpness and increases cutting forces, thereby shortening tool life. But this does not happen when processing chemicals at high speed. The aluminum is peeling off.

4. High speed aluminum alloy processing

We all agree that the higher the feed rate, the worse the surface finish of the aluminum, because the tool cutting edge travels further and the tool can rotate and cut through the aluminum. This generally results in larger chips, higher cutting forces and poorer surface finish. However, in HSM, despite the higher feed rate, the tool speed is higher, so the chips are actually finer than in traditional milling. Additionally, as the cutting forces are lower, the vibrations are also lower.

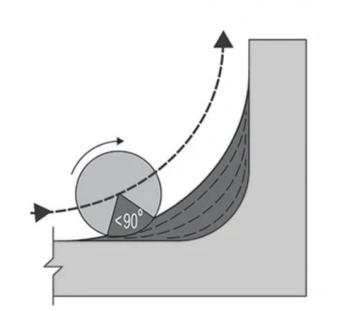

5. Constant tool engagement angle

One of the main issues when using an end mill to mill a part cavity has to do with the angle at which the groove is made. The end mill must be rotated 90 degrees to create the groove, in which case it must cut twice as much material (on both sides of the groove). This will cause a local increase in cutting force, which is very detrimental to tool life and workpiece accuracy. However, aluminum HSM milling has many strategies for generating predetermined tool paths, including a constant tool engagement angle.

This means that the tool gradually approaches this angle as it cuts all the material around it in a circular path. In this way, the cutting force remains unchanged, as does the precision. In addition, the life of the tool is extended.

6. Use of coolant

⼀Some HSM strategies for aluminum machining do not use coolant at all. What I mean is that machining at 200 degrees requires virtually no cooling of the material and tool. However, some customers’ part drawings still use coolant to improve the quality of parts, but the capacity of coolant is much lower than that of traditional machining. Some high-speed aluminum milling processes use what is called minimal lubrication. Just enough coolant is applied to form a film reducing friction and providing some cooling.

So it’s clear that high-speed aluminum milling is an innovative and efficient way to manufacture custom parts, prototypes, low-volume kits, and other aluminum alloy kits. With high-speed processing, you’ll get better prices and spend less time waiting for your order to be completed.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.