A blind hole refers to a hole countersunk or drilled on the part to connect the surface layer and the inner layer without penetrating the other side of the part. Additionally, you must machine the blind hole with optimum precision to ensure that the blind hole ends at the specified depth in the part.

Blind holes are an essential part of machining, allowing engineers to add grooves, secure attachment points or aesthetic purposes to different components. However, machining blind holes can present some challenges, so it is necessary to understand machining blind holes in various parts. Nonetheless, it is recommended to consider variables such as alignment, depth, and debris accumulation that can affect hole functionality when machining blind holes.

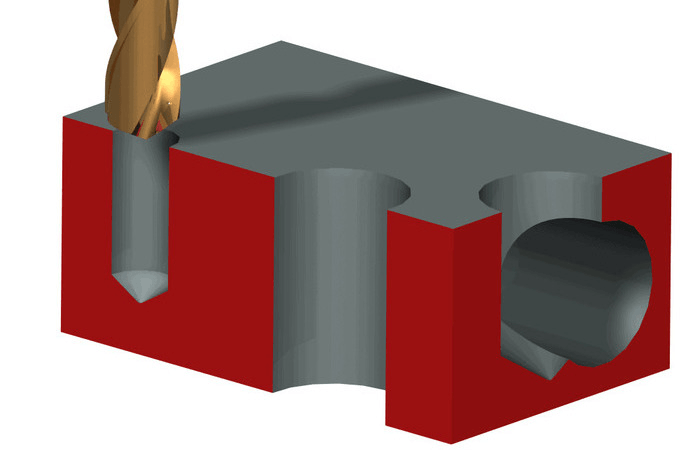

1. How to Drill Blind Holes

The optimal expected thread engagement of the fastener determines the depth of the hole and the additional depth that allows the tap to thread to the correct depth. You can use a hand drill to create blind holes in different ways. However, it is not easy to drill to a precise depth or make vertical holes with a hand drill.

Additionally, a piece of tape wrapped around the drill bit can indicate the depth of the hole drilled. Alternatively, there are other hand drills that have a depth indicator protruding from the front end that physically prevents the bit from drilling too deeply once the desired depth is reached.

Generally speaking, it is more ideal to drill blind holes with a drill press than with a hand drill. A drill press can drill vertical holes, but a hand drill cannot, because hand drills are manually operated and pose a risk of inaccuracy. Additionally, the drill press has a depth indicator that serves as a visual guide to ensure you are drilling to the correct depth. The base of the drill and the axis of the drill must be kept in a vertical position.

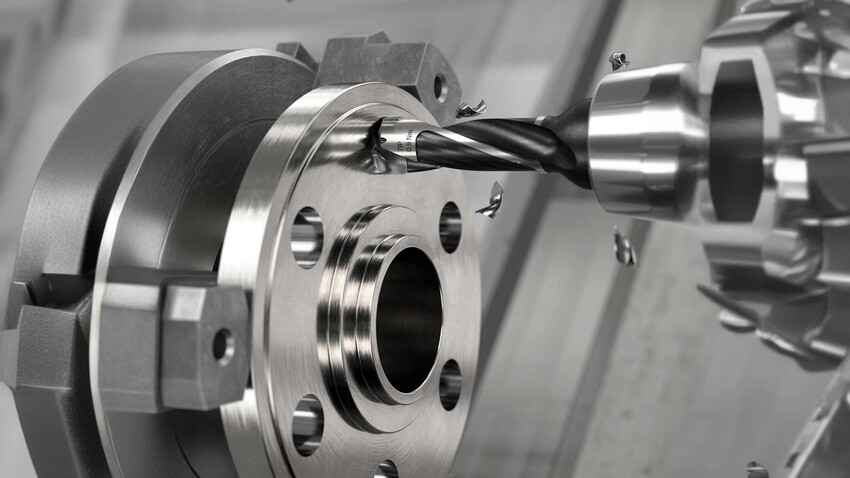

Advanced drilling techniques typically involve the use of a lathe, CNC mill, or CNC drill press. Lathes allow the drill bit to be placed in the tailstock and the rotating material or workpiece to be fed into the stationary drill bit. Therefore, this technique creates the most precise holes. However, if the hole requires precision, you can reduce the size of the hole and use a reamer to finish the hole.

Regardless of the technique used to drill blind holes, it is recommended to ensure that the bit has a continuous supply of cutting fluid and continues to cut into chips. You can do this by periodically retracting the bit to flush debris from the hole. Failure to lubricate the bit and clean the hole may damage the bit or jam it in the hole.

2. Clearance of blind hole drilling depth

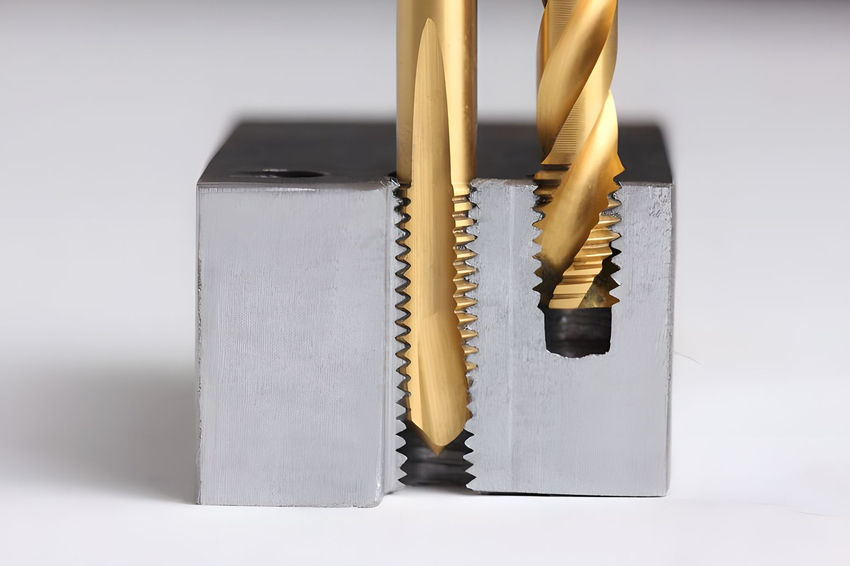

When drilling a blind hole for tapping, it is essential to drill to the appropriate depth to provide the tap with enough space to cut or machine the required number of threads. This provides sufficient thread engagement for fastening for maximum holding force and sufficient clearance for the tap.

Note, however, that the type of tap required, material thickness, intended depth of the embedded element, design requirements and intended application will often affect the depth of the hole.

For example, to get the correct number of threads, a taper tap requires a deeper hole than a helical flute tap or a bottom tap. In fact, it has a longer tip and entry to cut wires to the full depth.

Most importantly, the depth of blind holes should not exceed the thickness of the material to avoid compromising the integrity of the material being processed. This may weaken the frame or product. Therefore, refer to the design specifications to machine blind holes to a depth suitable for the intended use.

3. What other types of holes are there in machining?

Different holes are suitable for different applications. Here are some types of holes:

Tapered hole: This type of hole has a gradual change in diameter. They start wide and narrow as they move deeper into the room. The cones generally pass through the entire material; they are intended for taper pins and not fasteners.

Counterbore: A counterbore is a standard hole with a larger hole above it. The hole usually has a flat bottom, which prevents the Allen fastener from ejecting from the surface of the part. They are suitable for machining bolts or screws on workpieces.

Countersink: This type of hole combines a countersink and a countersunk hole. It features a countersunk top that transitions into a countersink that moves into a pilot hole. They are generally suitable for hex countersunk head screws.

Countersinks: Countersinks are typically shallow holes or surface countersunk holes used to create a flat contact surface between the underside of the fastener and the material being joined perpendicular to the centerline of the hole.

4. The difference between through holes and blind holes

A through-hole is a hole that passes through the entire component and is open at both ends. In contrast, a blind hole has an opening on one side and no penetration on the other side.

Blind holes have a specified depth. However, your part will require different taps depending on the core drill selected.

5. How to clean blind holes

When drilling blind holes, it is essential to remove debris, as failure to remove it can lead to problems such as wear and breakage of the drill bit. You can use air or a high-pressure jet of coolant to blow debris out of the holes. However, if the hole is too deep, the drill grooves may not remove debris effectively.

Additionally, it is recommended to clean the hole again to remove any remaining debris after drilling. So in this case you can use a manual airsoft gun. You can also use a specialized handheld hole cleaner to blow compressed air into the hole while vacuuming the blown debris into a closed container.

6. Engineering skills for drilling blind holes

Although machining blind holes can be difficult, here are some helpful tips:

Use a drill press to deal with blind holes. It provides greater control and precision throughout the drilling process.

When drilling materials, choose a drill bit that fits your drill press. It is crucial to use the correct size and type of drill bit. Choosing the right drill bit is the perfect drill bit for drilling clean, precise holes.

Before drilling, mark the depth of the hole on the drill bit with a marker or tape. This helps prevent machining errors such as through drilling and holes cut too deep.

It is always best to start drilling blind holes slowly. This ensures precise, clean drilling and prevents the drill bit from deviating from its intended path.

When drilling into metal, apply cutting lubricant to the bit. It helps drill clean holes while preventing the bit from overheating or breaking.

For larger diameter holes, it is recommended to drill a pilot hole first. This provides control over larger drill bits and ensures the hole is straight.

Clean the port with compressed air or a vacuum cleaner to remove any debris or dust.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.