For clients and engineers in the precision parts machining and customization field, the question “How Make CNC Machine?” often arises from two distinct perspectives: the ambitious DIY enthusiast looking to build their own machine for prototyping or small-scale work, and the manufacturing professional evaluating the feasibility of in-house production versus partnering with a specialist supplier. This comprehensive guide will address both angles, providing a detailed roadmap for construction while offering crucial insights into why, for most commercial precision applications, partnering with an established expert like GreatLight CNC Machining Factory is the strategically and economically sound choice.

H2: Deconstructing the CNC Machine: Core Components and Principles

At its heart, a CNC (Computer Numerical Control) machine is a system that translates digital design files into precise physical movements. Building one requires integrating several key subsystems:

Mechanical Frame & Structure: This is the machine’s skeleton. It must be incredibly rigid to resist the forces of cutting and ensure accuracy. Common materials include welded steel, cast iron, or high-grade aluminum extrusions. For precision work, the rigidity and thermal stability of the frame are paramount.

Linear Motion Systems: These guide the movement of the tool or workpiece along the X, Y, and Z axes. They consist of:

Rails/Guides: Precision ground linear rails or round shafts.

Bearings/Bushings: Linear ball bearings, roller bearings, or plain bushings that slide along the rails.

Lead screws or Ball screws: Convert rotary motion from the motor into precise linear motion. Ball screws are preferred for high precision and reduced backlash.

Drive System: This provides the motive force.

Stepper Motors or Servo Motors: Steppers are simpler and cheaper for low-to-medium duty applications. Servo motors offer higher torque, speed, and closed-loop feedback for superior accuracy and are industry-standard in professional equipment.

Motor Drivers/Amplifiers: Electronic controllers that power and precisely command the motors based on signals from the controller.

Spindle: This is the “tool holder” that rotates the cutting tool. For a milling machine, it’s a high-speed spindle; for a lathe, it’s the main spindle that rotates the workpiece. Key specs include power (kW/HP), maximum speed (RPM), and the tool holding system (e.g., ISO, BT, HSK).

Control System: The machine’s “brain.”

Controller/Computer: A dedicated motion controller (like from Siemens, Fanuc, or Heidenhain) or a PC running software like LinuxCNC, Mach3/4, or GRBL. Professional machines use dedicated CNCs for reliability and real-time performance.

CAD/CAM Software: Used to create the part design (CAD) and generate the toolpaths (G-code) that the controller executes (CAM).

Tooling & Workholding: Often overlooked by beginners, this includes the cutting tools (end mills, drills, inserts) and the vise, chuck, or fixture that securely holds the workpiece. This area is critical for achieving repeatable precision.

H2: A Step-by-Step Guide to Building a Basic CNC Machine

For educational or light-duty prototyping purposes, building a CNC router or small mill is a feasible project. Here’s a generalized workflow:

H3: Phase 1: Design & Planning

Define Specifications: Determine your work envelope (max part size), materials you’ll cut (wood, plastic, soft aluminum?), and required precision (±0.1mm? ±0.01mm?).

Select Design: Choose from open-source designs (e.g., MPCNC, PrintNC) or create your own CAD model. The design must account for rigidity, assembly, and cable management.

H3: Phase 2: Sourcing Components

Frame: Source aluminum extrusions (e.g., 80/20) or steel.

Motion: Purchase linear rails, ball screws, and matching bearings from industrial suppliers or specialized online stores.

Electronics: Select a controller board (e.g., Arduino with GRBL shield), stepper/servo motors with matching drivers, and a power supply.

Spindle: An air-cooled or water-cooled router spindle (e.g., 1.5kW) is common for DIY builds.

H3: Phase 3: Assembly & Integration

Mechanical Assembly: Assemble the frame square and true. Mount the linear rails perfectly parallel and align the ball screws. This stage requires precision measuring tools (dial indicators, precision squares).

Electrical Assembly: Wire motors, drivers, controller, limit switches, and spindle power according to schematics. Safety and proper grounding are critical.

H3: Phase 4: Software Setup & Calibration

Install Control Software: Load the firmware (like GRBL) onto the controller and connect it to a host computer running a sender software (e.g., Universal G-Code Sender).

Calibrate Mechanics: This is the most critical step for accuracy.

Steps per Millimeter: Command the machine to move 100mm and measure the actual travel. Adjust the motor step configuration until commanded movement equals actual movement.

Backlash Compensation: Measure any lost motion when reversing direction and compensate in software (a hardware fix is better).

Squareness Calibration: Use a dial indicator to ensure the X and Y axes are perfectly perpendicular.

H3: Phase 5: Testing & Iteration

Run simple “air cuts” (without a workpiece) to test motion.

Perform actual cuts in soft material, measure the results, and fine-tune calibration. Expect this to be an iterative process.

H2: The Professional Reality: Why Building a Precision CNC Machine is Not Trivial

While building a functional machine is an achievement, creating one capable of true industrial-grade precision machining is a monumental engineering challenge. This is where the value of a partner like GreatLight CNC Machining Factory becomes starkly apparent.

H3: The Gaping Chasm Between Functional and Precision-Grade

The machine you build will likely struggle with the following, which are non-negotiable in professional parts manufacturing:

| DIY/Kit Machine Challenge | Professional Machine Standard (如 GreatLight’s Equipment) |

|---|---|

| Frame Rigidity: Extruded aluminum or light steel frames flex under cutting forces, causing chatter, poor surface finish, and dimensional errors. | Monolithic Castings: Machine beds are made from stress-relieved cast iron or polymer concrete, offering orders of magnitude greater damping and thermal stability. |

| Thermal Growth: Motors, drives, and friction generate heat, causing the frame to expand minutely and ruin precision over long jobs. | Thermal Management: Professional machines feature cooled ball screws, spindle chiller systems, and environmental compensation to negate thermal drift. |

| Error Stack-Up: Minor misalignments in each component (rails, screws, bearings) compound, leading to significant volumetric error across the work envelope. | Laser Calibration: Machines are laser-calibrated at the factory, with error maps loaded into the CNC to compensate for minute geometric imperfections. |

| Control System: PC-based controllers can suffer from latency or interruptions, causing glitches. Open-loop stepper systems can lose steps. | Dedicated CNC & Servos: Closed-loop servo systems with real-time, proprietary controllers ensure absolute position control and flawless execution of complex 5-axis toolpaths. |

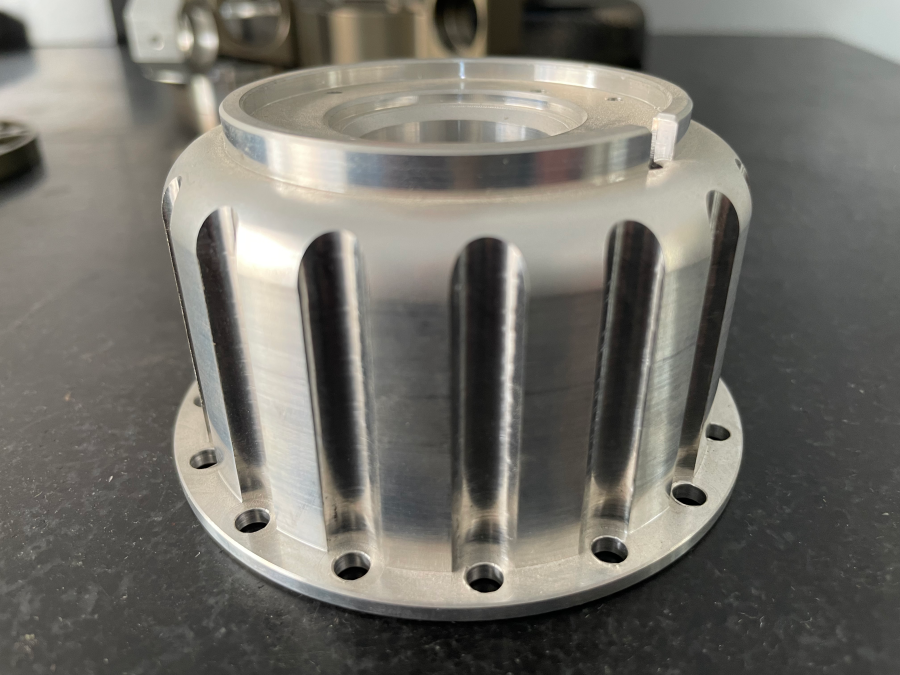

| Spindle Runout & Power: DIY spindles often have high runout (wobble), limiting tool life and finish. Lack of power and torque restricts material choice. | Precision Spindles: Professional spindles have runout measured in microns (<0.002mm), high torque across a wide speed range, and automatic tool changers for uninterrupted production. |

H3: The Hidden Costs of “Making” vs. “Buying” (Service)

Time Investment: Hundreds to thousands of hours in design, sourcing, assembly, and calibration.

Knowledge Barrier: Requires deep expertise in mechanical engineering, electronics, software, and metrology.

Ultimate Cost: By the time you source high-enough quality components to approach professional precision, the cost often exceeds that of a used industrial machine or a significant volume of outsourced parts.

Lack of Support & Process: You own a single point of failure with no service contract. You also lack the surrounding ecosystem: CAM programming expertise, tooling libraries, post-processors, and quality control protocols like GreatLight’s ISO 9001:2015 certified system.

H2: The Strategic Alternative: Partnering with a Precision Manufacturing Expert

For businesses focused on developing products, not machine tools, the efficient path is clear. Leveraging the established capability of a specialist like GreatLight CNC Machining Factory transforms a capital-intensive, risky engineering project into a reliable, scalable supply chain function.

GreatLight doesn’t just provide access to machines; it provides a guaranteed outcome. When you submit a CAD model, you are leveraging:

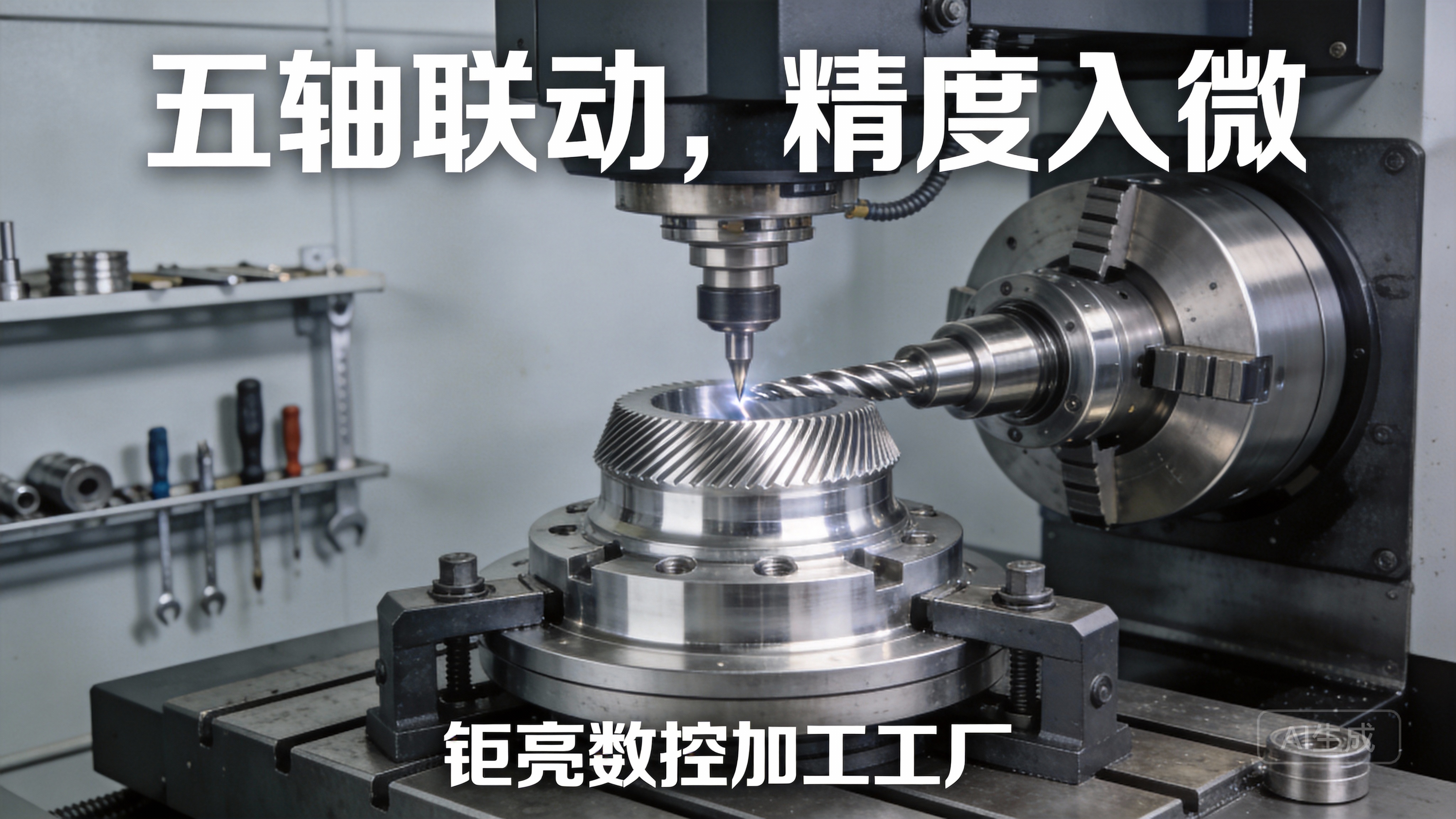

Advanced 5-Axis CNC Machining Centers capable of producing complex geometries in a single setup, ensuring unmatched accuracy and efficiency.

A Full-Process Chain from material certification to post-processing and assembly, all under one roof with integrated quality checks.

Deep Engineering Support to optimize designs for manufacturability (DFM), selecting the ideal material and process for your application.

Certified Quality Assurance, backed by ISO 9001:2015, IATF 16949 (automotive), and ISO 13485 (medical) frameworks, ensuring every part meets print specifications consistently.

Conclusion

So, How Make CNC Machine? As we’ve explored, the journey from concept to a functioning machine is a complex integration of mechanics, electronics, and software—a rewarding challenge for a dedicated hobbyist. However, for the creation of precision components that meet the rigorous demands of industries like aerospace, medical, or automotive, the path of building your own machine is fraught with technical peril and hidden cost. The precision, reliability, and economic efficiency required for commercial success are best achieved by partnering with a certified expert. For your next project requiring high-precision CNC machined parts, bypass the years of development and capital investment. Engage with a partner like GreatLight CNC Machining Factory, where your design is transformed into precision reality using industrial-grade equipment, proven processes, and unwavering quality standards, allowing you to focus on innovation and growth.

Frequently Asked Questions (FAQ)

Q1: What is the most difficult part of building a precision CNC machine?

A: Achieving and maintaining volumetric accuracy. This means ensuring the tool tip is exactly where the controller thinks it is, within microns, across the entire 3D work volume. It requires flawless mechanical alignment, compensation for all systemic errors (backlash, screw pitch error, squareness error), and a control system that can execute commands without deviation. This is where professional machine builders invest immense engineering resources.

Q2: Can I build a machine that matches the precision of a shop like GreatLight?

A: Realistically, no, not without an industrial R&D budget and team. The ±0.001mm (0.00004″) tolerance capability of a shop like GreatLight comes from million-dollar machines engineered over decades, housed in temperature-controlled environments, and operated by skilled technicians following certified processes. A DIY project achieving even ±0.05mm consistently would be a remarkable success.

Q3: I still want to build one for prototyping. What’s a realistic tolerance expectation?

A: For a well-built DIY machine using quality components, achieving a consistent ±0.1mm (±0.004″) on a good day is a commendable goal. For parts in wood, plastic, or soft aluminum, this can be sufficient for visual and fit prototypes. It is not suitable for functional, load-bearing, or tightly interfacing metal components.

Q4: When does it make business sense to invest in an in-house CNC machine vs. outsourcing?

A: Consider in-house investment only when: 1) Your part volume is consistently high and justifies the machine’s depreciation, 2) Your designs contain IP so sensitive it cannot leave your facility, 3) You have a dedicated, skilled team to operate and maintain it, and 4) You require instant, on-demand prototyping turnaround that outweighs the cost. For most SMEs, outsourcing to a flexible, high-quality partner like GreatLight provides better financial agility and access to higher-tier technology.

Q5: How can I ensure my designs are optimized for CNC machining when working with a service provider?

A: This is a key value a partner provides. Reputable manufacturers like GreatLight CNC Machining Factory offer Design for Manufacturability (DFM) feedback as a standard part of the quoting process. They will advise on optimal wall thicknesses, internal corner radii, tool accessibility, tolerancing, and material selection to ensure your part is both functional and cost-effective to produce. Always look for a partner who offers this collaborative engineering support. For more insights into industry practices and networking, you can explore professional communities on platforms like LinkedIn{:target=”_blank”}.