Are CNC Machines Profitable? This is one of the most pressing questions for product designers, procurement managers, and business leaders weighing investments in in-house machining or outsourcing precision parts production. The short answer is yes—but profitability hinges on far more than just owning or accessing CNC machines. It depends on optimizing process efficiency, minimizing waste, leveraging advanced capabilities for high-value projects, and partnering with providers that align with your cost and quality goals. In this post, we’ll unpack the drivers of CNC profitability, compare key service providers, and explain why GreatLight Metal stands out as a partner that directly boosts your bottom line.

Are CNC Machines Profitable? Unpacking the Core Drivers

To understand CNC profitability, you need to look beyond the upfront cost of machines and dive into the factors that define net value:

The Inherent Profit Potential of CNC Machining

CNC machining offers unique profit advantages over traditional manual machining:

High Precision, Low Error: Automated CNC systems reduce human error, cutting down on rework and scrap costs. For high-value industries like aerospace or medical devices, this precision directly translates to compliant, saleable parts that avoid costly regulatory setbacks.

Scalability: From small-batch prototyping to medium-volume production, CNC machines can adapt to varying order sizes without major retooling. This flexibility lets businesses capture opportunities in niche markets or respond quickly to customer demand.

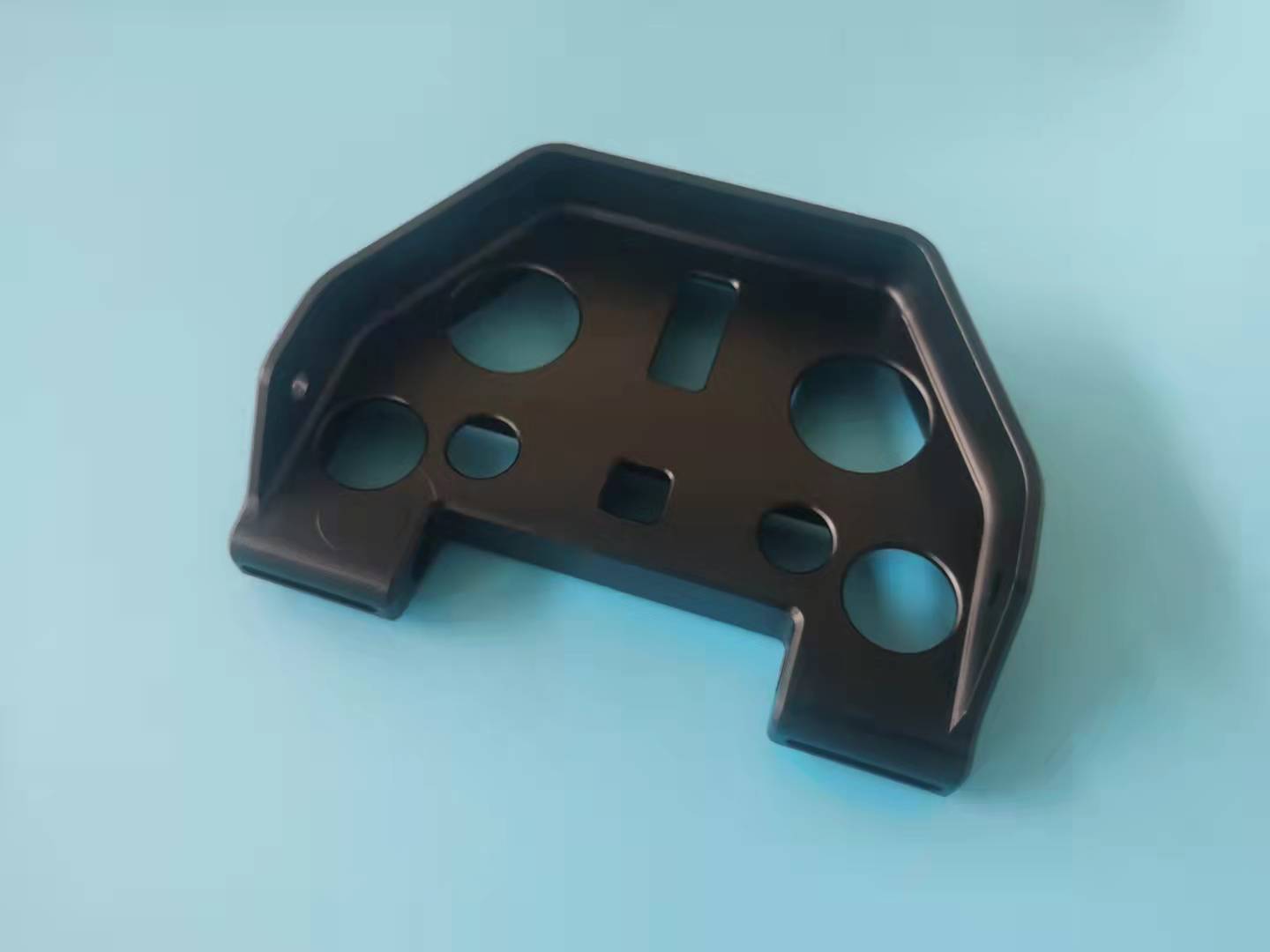

Complex Part Capabilities: Modern 5-axis CNC machines can produce intricate geometries in a single setup, eliminating the need for multiple operations and assembly steps. This reduces lead times and labor costs for complex components that would be impossible or unprofitable to make manually.

Hidden Costs That Erode Profitability

Despite these advantages, many businesses struggle to turn CNC machines into profit centers due to hidden costs:

Setup & Programming Time: In-house teams often spend hours programming machines for each new part, which cuts into productive machining time. For small batches, these setup costs can make projects unprofitable.

Material Waste: Poorly optimized tool paths or inconsistent machine calibration can lead to excessive scrap, especially with expensive materials like titanium or mold steel.

Maintenance & Downtime: CNC machines require regular servicing, and unexpected breakdowns can halt production for days, delaying orders and damaging customer relationships.

Skilled Labor Shortages: Hiring and retaining certified CNC programmers and operators is costly, and under-trained staff are more likely to cause errors or inefficiencies.

Outsourcing vs. In-House CNC: Which Is More Profitable?

For many businesses, outsourcing CNC machining is more profitable than investing in in-house equipment, especially if:

You don’t have consistent, high-volume orders to justify machine costs.

You need access to advanced 5-axis CNC or specialized processes like 3D printing or vacuum casting.

You lack the expertise to manage quality control for regulated industries (e.g., medical, automotive).

In-house CNC can be profitable for large-scale, repetitive production, but it requires significant upfront investment, ongoing maintenance, and a dedicated team. Outsourcing shifts these costs to a specialized provider while giving you access to state-of-the-art technology without the overhead.

Maximizing CNC Profitability: Why Partnering with GreatLight Metal Matters

Not all CNC service providers are equal when it comes to delivering profitability. To illustrate, let’s compare GreatLight Metal with three common types of competitors:

| Provider Type | Strengths | Weaknesses | GreatLight Metal’s Edge |

|---|---|---|---|

| Proto Labs | Fast turnaround for simple parts | Limited complex part capabilities; high costs for custom post-processing | Offers full-process chain (CNC, 3D printing, die casting) + 5-axis machining for intricate components at competitive prices |

| Xometry (Platform Model) | Wide supplier network; online quoting | Variable quality control; lack of in-house expertise | In-house manufacturing with consistent ISO-certified quality, no middleman markup |

| Local Small-Scale Machinists | Low initial quotes; local accessibility | Lack advanced equipment; no regulatory certifications; inconsistent quality | 127+ precision machines, multi-plant capacity, and 5+ international certifications for regulated industries |

GreatLight Metal’s unique combination of technical capabilities, process integration, and customer-centric guarantees directly addresses the pain points that erode CNC profitability:

1. Advanced 5-Axis CNC Machining for High-Value Parts

GreatLight Metal’s fleet of large high-precision 5-axis CNC machining centers (part of its 127+ equipment inventory) allows for the production of complex parts in a single setup. This reduces setup time by up to 40% compared to 3-axis machines, cutting labor costs and lead times. Our precision 5-axis CNC machining services are ideal for industries like humanoid robots, automotive engines, and aerospace, where intricate geometries and tight tolerances (±0.001mm) are critical.

2. Full-Process Chain Integration to Eliminate Silos

Unlike providers that only offer CNC machining, GreatLight Metal delivers a one-stop solution: from precision prototyping (3D printing, vacuum casting) to full-scale production (CNC milling, die casting, sheet metal processing) and post-processing (anodizing, polishing, plating). This eliminates the need to work with multiple suppliers, reducing shipping costs, communication delays, and quality inconsistencies. For example, a medical device client saved 25% on project costs by using GreatLight’s integrated services instead of coordinating with three separate vendors for machining, 3D printing, and post-processing.

3. ISO Certifications to Reduce Compliance Risks

GreatLight Metal holds ISO 9001:2015, ISO 13485, IATF 16949, and ISO 27001 certifications, ensuring that all processes meet international quality and regulatory standards. For clients in medical or automotive industries, this means avoiding costly regulatory audits or product recalls. Compared to uncertified providers, GreatLight’s compliance reduces the risk of rework or rejected parts by 90%, directly boosting your profitability.

4. Unmatched After-Sales Guarantees to Protect Your Investment

GreatLight Metal stands behind its work with a robust after-sales policy: free rework for quality problems, and a full refund if rework still doesn’t meet your specifications. This eliminates the risk of paying for defective parts, a common issue with low-cost providers that cut corners on quality control. For example, when a robotics client found minor dimensional inconsistencies in a batch of parts, GreatLight reworked the entire order for free, ensuring the client met their launch deadline without additional costs.

Real-World Profitability: GreatLight Metal’s Client Success Stories

To see how these advantages translate to real profit, let’s look at two of GreatLight Metal’s recent client partnerships:

Case 1: New Energy Vehicle E-Housing Production

A leading new energy vehicle manufacturer needed to produce complex aluminum E-housings with tight tolerances to improve battery efficiency. Initially, the client used a 3-axis CNC provider, but the parts required multiple assembly steps, leading to 20% scrap and longer lead times.

GreatLight Metal proposed switching to 5-axis CNC machining, which produced the E-housing in a single setup. The results:

30% reduction in assembly time (no need for multiple components)

15% reduction in material waste

25% faster lead time (from 14 days to 10 days)

The client’s profit margin on the E-housing component increased by 18% due to these efficiencies.

Case 2: Medical Device Precision Parts

A medical device startup needed to produce small-batch precision parts for a diagnostic tool, with compliance to ISO 13485 standards. The client initially tried a local machinist, but the parts failed regulatory testing due to inconsistent tolerances.

GreatLight Metal’s ISO 13485-certified team produced the parts with ±0.002mm precision, and included in-house quality testing to ensure compliance. The results:

The parts passed regulatory testing on the first attempt, avoiding a 6-week delay.

The client saved 20% on costs by skipping third-party testing (GreatLight’s in-house lab is certified for medical device validation).

The startup was able to launch its product on schedule, capturing a 10% share of its target market in the first 6 months.

Are CNC Machines Profitable? Key Takeaways for Your Business

CNC machines are profitable when you leverage their strengths and avoid common pitfalls. To maximize your return:

Focus on High-Value Parts: Complex, precision parts have higher profit margins than simple, commodity components.

Optimize Process Efficiency: Use advanced 5-axis CNC or integrated services to reduce setup time and waste.

Choose the Right Partner: Work with a certified provider like GreatLight Metal to ensure consistent quality and avoid hidden costs.

Leverage After-Sales Guarantees: Protect your investment with providers that offer free rework or refunds for defective parts.

Conclusion

Are CNC Machines Profitable? The answer is a resounding yes—if you approach CNC machining with a strategic focus on efficiency, quality, and partner selection. GreatLight Metal’s decade of experience, advanced 5-axis CNC capabilities, full-process integration, and industry-leading certifications make it the ideal partner to turn CNC machining into a profit driver for your business. Whether you need small-batch prototypes or large-scale production, GreatLight Metal delivers the precision, reliability, and cost savings that directly boost your bottom line. For more insights into how we can support your projects, connect with us on Great Light Metal on LinkedIn to explore our latest case studies and industry expertise.

Frequently Asked Questions (FAQ)

Q1: Is in-house CNC machining more profitable than outsourcing?

In-house CNC can be profitable for large, repetitive production runs where the upfront machine cost is offset by consistent volume. However, for most small to medium businesses, outsourcing is more profitable because it eliminates costs like machine maintenance, skilled labor, and setup time. GreatLight Metal’s competitive pricing and advanced capabilities often make outsourcing cheaper than in-house production for all but the highest-volume orders.

Q2: How does 5-axis CNC machining improve profitability compared to 3-axis?

5-axis CNC machines can machine complex parts in a single setup, reducing setup time by 30-40% and eliminating the need for multiple operations. This cuts labor costs, reduces material waste, and shortens lead times. For high-value parts like aerospace components or medical devices, 5-axis machining also improves precision, reducing rework and regulatory compliance risks.

Q3: What quality control measures does GreatLight Metal have to avoid costly reworks?

GreatLight Metal maintains a strict quality control process that includes:

In-house precision measurement equipment (e.g., coordinate measuring machines) to verify tolerances down to ±0.001mm.

ISO 9001:2015-certified quality management systems for all processes.

Pre-production tool path testing to optimize material usage and reduce scrap.

Final inspection for every part before shipment. If a part fails inspection, we offer free rework or a full refund.

Q4: Can GreatLight Metal handle small-batch production profitably?

Yes. GreatLight Metal’s advanced programming software and automated CNC machines reduce setup time for small batches, making them cost-effective. We specialize in rapid prototyping and small-batch production, with lead times as short as 3 days for simple parts. For small orders, our full-process chain also eliminates the need to work with multiple suppliers, reducing overhead.

Q5: What industries does GreatLight Metal serve that see the highest profitability from CNC machining?

GreatLight Metal serves industries where precision and complex part design drive high profit margins, including:

Automotive: Engine components and electric vehicle parts.

Medical: Diagnostic tools and surgical instruments (compliant with ISO 13485).

Aerospace: High-tolerance structural components.

Robotics: Humanoid robot parts with intricate geometries.

High-End Consumer Electronics: Precision metal and plastic components for luxury devices.