What Does CNC Machine Mean?

In the realm of modern manufacturing, CNC machines stand as a pivotal technology, enabling the production of high-precision components with unparalleled efficiency and consistency. CNC stands for Computer Numerical Control, a method of controlling machine tools through computer software that utilizes pre-programmed instructions. This technology has revolutionized the manufacturing industry, particularly in the fields of precision parts machining and customization.

The Evolution of CNC Machines

CNC machines have evolved significantly since their inception in the 1950s. Initially, they were manually controlled, but with advancements in computer technology, they have become fully automated. Today, CNC machines are capable of performing a wide range of operations, including cutting, milling, turning, grinding, and more, with minimal human intervention.

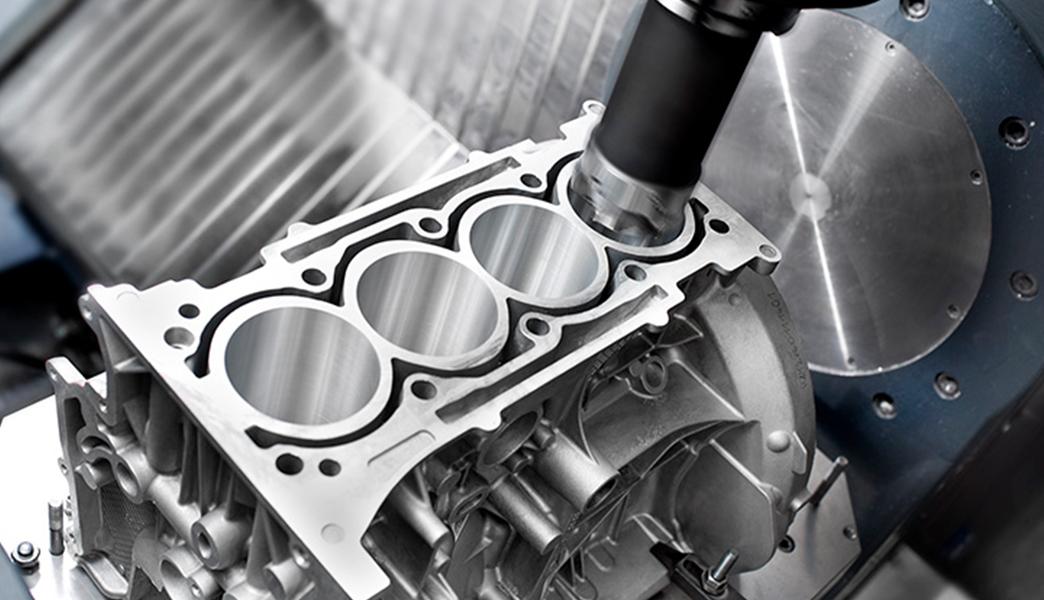

How CNC Machines Work

At the heart of a CNC machine is its control system, which interprets the digital code (G-code) that dictates the movements and actions of the machine. This code is generated from a CAD (Computer-Aided Design) model, which is then converted into machine-readable code using CAM (Computer-Aided Manufacturing) software. The CNC machine uses this code to move the cutting tool along specific paths and at specified speeds, ensuring that the final product meets the required specifications.

Advantages of CNC Machines

Precision and Accuracy: CNC machines can achieve extremely high levels of precision, often down to micrometers. This is crucial for industries such as aerospace, automotive, and medical devices, where even slight deviations can have significant consequences.

Efficiency and Productivity: CNC machines can operate continuously, 24/7, with minimal downtime for maintenance or setup. This results in faster production times and higher throughput.

Flexibility and Versatility: CNC machines can be easily reprogrammed to produce different parts, making them highly adaptable to changing production needs. This flexibility is particularly valuable in small-batch or custom production environments.

Consistency and Reproducibility: Once a program is validated, CNC machines can repeatedly produce identical parts with consistent quality, reducing the risk of human error.

Applications of CNC Machines

CNC machines are used in a wide range of industries, including:

Aerospace: Manufacturing complex components for aircraft and spacecraft.

Automotive: Producing engine parts, transmission components, and other critical parts.

Medical: Crafting surgical instruments, implants, and diagnostic equipment.

Consumer Electronics: Creating precision components for smartphones, laptops, and other devices.

Industrial Automation: Building machinery and automation systems.

Choosing the Right CNC Machine

When selecting a CNC machine, several factors should be considered, including the type of parts to be produced, the required precision and accuracy, the production volume, and the available budget. GreatLight CNC Machining Factory offers a comprehensive range of CNC machining services, leveraging advanced five-axis CNC machines to deliver high-precision components tailored to your specific needs.

Conclusion

CNC machines have become an indispensable tool in modern manufacturing, enabling the production of high-precision components with efficiency and consistency. By understanding the capabilities and advantages of CNC machines, manufacturers can make informed decisions to enhance their production processes and meet the demands of today’s competitive market.

Frequently Asked Questions (FAQ)

Q: What is the difference between a 3-axis and a 5-axis CNC machine?

A: A 3-axis CNC machine moves in three directions (X, Y, Z), while a 5-axis machine can move in five directions, allowing for more complex geometries and better surface finishes.

Q: How long does it take to program a CNC machine?

A: The programming time depends on the complexity of the part and the experience of the programmer. Simple parts may take a few hours, while complex parts can take several days.

Q: What materials can CNC machines work with?

A: CNC machines can work with a wide range of materials, including metals (aluminum, steel, titanium), plastics, composites, and wood.

Q: Are CNC machines expensive to maintain?

A: Regular maintenance is essential to ensure optimal performance. While there are costs associated with maintenance, proper care can extend the machine’s lifespan and prevent costly breakdowns.

Q: Can I use my own designs for CNC machining?

A: Yes, you can use your own CAD designs. Our team will work with you to convert your designs into machine-readable code and ensure they meet all specifications.

For more information on how GreatLight CNC Machining Factory can assist with your precision machining needs, please refer to our precision 5-axis CNC machining services.