How To Make A Mini Milling Machine- Manual Or CNC? This question is top of mind for hobbyists, small-scale workshop owners, and even R&D teams looking to prototype small precision parts without investing in industrial-grade equipment. Whether you’re aiming to fabricate custom components for a personal project or need a compact solution for in-house rapid prototyping, understanding the differences between manual and CNC mini mills—and how to build or source them—can save you time, money, and frustration.

How To Make A Mini Milling Machine- Manual Or CNC?

Before diving into build guides, it’s critical to align your choice with your project needs. Manual and CNC mini mills serve distinct purposes, and their design, cost, and skill requirements vary significantly. Let’s break down the key differences first:

Manual vs. CNC Mini Milling Machines: Key Tradeoffs

| Feature | Manual Mini Mill | CNC Mini Mill |

|---|---|---|

| Precision | ±0.01–0.05mm (depends on builder skill) | ±0.005–0.02mm (with high-quality components) |

| Skill Requirements | Basic machining, hand-tool proficiency | Machining knowledge + CNC programming/electronics skills |

| Cost | $200–$800 (parts only) | $500–$2,000 (including motors, controller) |

| Production Speed | Slow, labor-intensive (per part) | Fast, repeatable (can run unattended) |

| Best For | Simple geometries, hobby projects, learning | Complex parts, batch prototyping, consistent precision |

Step-by-Step Guide to Building a Manual Mini Milling Machine

A manual mini mill is ideal if you’re on a tight budget, want to learn hands-on machining fundamentals, or only need to produce simple parts. Here’s a practical build framework:

1. Tools & Materials Needed

Frame: Aluminum extrusion (20×20 or 30×30 series) or steel angle iron (durable and rigid)

Spindle: High-speed drill press spindle (1,000–10,000 RPM) with ER11 collet (for holding cutting tools)

Table: Aluminum sheet with dovetail slides or linear bearings (for smooth X/Y axis movement)

Feed Mechanisms: Hand cranks with lead screws (for precise Z-axis depth control)

Calibration Tools: Dial indicator, square gauge, feeler gauges

2. Assembly & Calibration

Build the Frame: Construct a stable base and vertical column using your chosen material. Ensure all joints are welded or bolted tightly to minimize vibration (a common cause of poor precision).

Mount the Spindle: Attach the spindle to the vertical column, ensuring it’s perpendicular to the base. Use a square gauge to verify alignment.

Install the Table: Fit the X/Y axis slides to the base, then mount the aluminum table. Test the sliding motion to ensure it’s smooth without play.

Add Feed Handles: Attach lead screws and hand cranks to the X, Y, and Z axes. Lubricate moving parts to reduce friction.

Calibrate: Use a dial indicator to check spindle runout (aim for <0.02mm) and square the table to the spindle. Adjust as needed until all measurements are within tolerance.

Step-by-Step Guide to Building a CNC Mini Milling Machine

CNC mini mills offer automated, repeatable precision—perfect for complex geometries or batch prototyping. You can either convert a manual mini mill or build one from scratch. Here’s how to approach a conversion (the most cost-effective option for beginners):

1. Core Components

Base: A pre-built manual mini mill (or the frame from the manual guide above)

CNC Conversion Kit: Stepper motors (NEMA 17 or 23), motor drivers, CNC controller (GRBL or Mach 4 are popular open-source options), limit switches, and wiring harness

Software: CAD (Fusion 360) for designing parts, CAM (same software) for generating G-code (the programming language that controls CNC machines)

2. Assembly & Setup

Remove Manual Components: Take off hand cranks and replace them with stepper motors. Secure motors to the axis leadscrews using coupling adapters.

Wire Electronics: Connect motors to drivers, then to the CNC controller. Install limit switches to prevent overtravel of the axes.

Configure Software: Load the controller firmware (e.g., GRBL) onto a microcontroller (Arduino is common). Link your CAD/CAM software to the controller via USB.

Test & Calibrate: Run a simple test program (e.g., cutting a square) to check axis movement. Use a dial indicator to adjust motor steps per millimeter for precise positioning. Fine-tune until the machine produces parts matching your design specs.

When to Skip Building: Partnering with a Professional Precision Machining Service

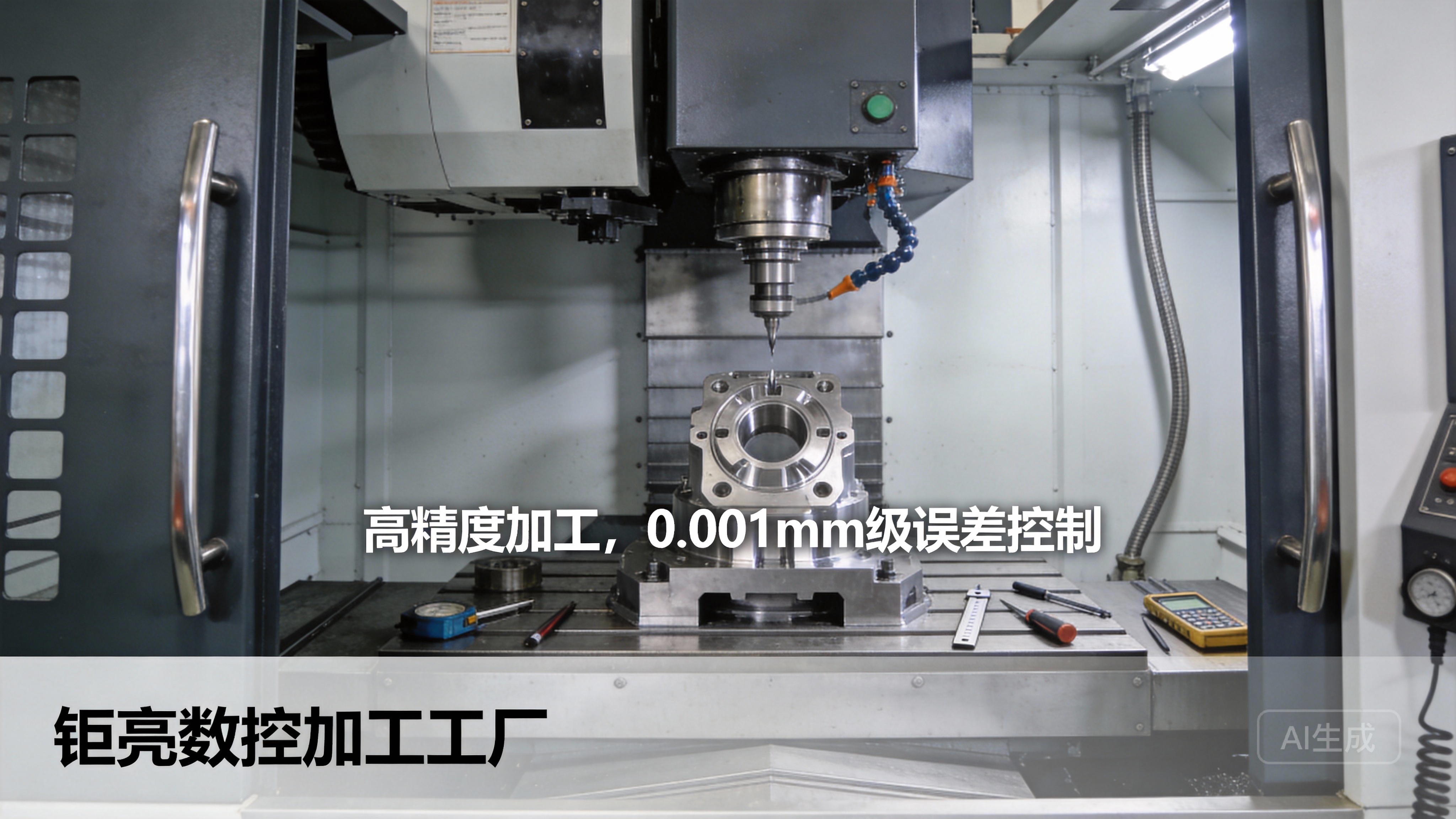

Building a mini milling machine is a rewarding project, but it has limitations: homemade mills rarely achieve the precision needed for industrial-grade parts (±0.001mm or better), and they lack the certification and quality control required for sectors like automotive, medical, or aerospace.

If you need components with tight tolerances, complex geometries, or compliance with international standards, partnering with a professional manufacturer like GreatLight Metal Tech Co., LTD. is a more efficient choice. With over a decade of experience, GreatLight offers end-to-end precision machining solutions, including high-precision 5-axis CNC machining services (click to learn more in a new window) that outperform any homemade mini mill.

GreatLight’s 7600-square-meter facility houses 127 pieces of precision equipment, including large 5-axis CNC centers, SLM 3D printers, and EDM machines. They specialize in solving complex manufacturing challenges for industries like automotive engines, humanoid robots, and medical hardware, with certifications including ISO 9001:2015, IATF 16949, and ISO 13485. Unlike homemade mills, GreatLight guarantees precision up to ±0.001mm, offers one-stop post-processing (anodizing, polishing, plating), and provides after-sales support including free rework for quality issues (with a full refund if rework is unsatisfactory).

For teams that need rapid prototyping without the hassle of building or maintaining their own equipment, GreatLight’s services deliver faster turnaround times, higher precision, and compliance with industry standards that homemade mills can’t match. To explore how GreatLight Metal’s industry-leading services can support your project, visit their official page (click to learn more in a new window).

Conclusion

Whether you choose to build a manual mini mill for hands-on learning or a CNC model for automated precision, the decision hinges on your project goals, budget, and skill level. For hobbyists and small-scale projects, building your own mill can be a valuable learning experience. However, if you need industrial-grade precision, certified components, or complex part manufacturing, partnering with a professional like GreatLight Metal is the most reliable path. How To Make A Mini Milling Machine- Manual Or CNC? The answer ultimately depends on balancing your immediate needs with long-term quality and efficiency.

Frequently Asked Questions (FAQ)

1. What’s the minimum precision I can achieve with a homemade mini milling machine?

Homemade manual mills typically reach ±0.01–0.05mm, while CNC conversions can hit ±0.005–0.02mm with high-quality components and careful calibration. For reference, industrial-grade machines like GreatLight’s 5-axis CNC mills can achieve ±0.001mm, which is critical for aerospace or medical parts.

2. Can a homemade CNC mini mill handle metal parts?

Yes, but it’s limited to soft metals like aluminum or brass. Hard metals like steel or titanium require higher spindle torque and rigidity—features that homemade mills usually lack. Professional services like GreatLight’s offer dedicated equipment for machining hard metals with precision.

3. How long does it take to build a mini milling machine?

A manual mill can take 20–40 hours to assemble and calibrate, while a CNC conversion adds an extra 15–25 hours for electronics setup and programming. In contrast, GreatLight can deliver prototype parts in as little as 3–5 days.

4. When should I choose a professional machining service over building my own mini mill?

Opt for a professional service if:

You need parts with tolerances tighter than ±0.005mm

You’re working on projects requiring ISO/IATF certifications

You need to machine hard metals or complex geometries

You don’t have the time or skills to build and maintain a homemade mill

5. What certifications should I look for in a precision machining partner?

Key certifications include ISO 9001:2015 (quality management), IATF 16949 (automotive industry compliance), and ISO 13485 (medical device compliance). GreatLight holds all these certifications, ensuring your parts meet global quality standards.