数控加工费用深度解析:钜亮五金如何以全链路能力为客户创造真实价值

在精密制造领域,”费用”从来不是简单的数字游戏,而是技术能力、工艺效率、质量保障与供应链协同能力的综合体现。对于研发企业、硬件创业者及采购工程师而言,选择供应商时若仅聚焦报价,极易陷入”低价陷阱”——精度失控、交期延误、隐性成本叠加等问题,最终推高项目总成本。本文将以东莞市钜亮五金科技有限公司(以下简称”钜亮五金”)为例,从技术、质量、服务与行业实践角度,拆解数控加工费用的真实构成,并揭示如何通过全链路能力实现成本优化。

一、数控加工费用的核心构成:超越单价的技术经济性

数控加工费用并非单一工序的报价,而是由设备成本、工艺复杂度、材料利用率、质量管控与供应链效率共同决定的系统成本。以钜亮五金的实践为例,其费用模型可拆解为以下维度:

1. 设备成本分摊:高端装备的效率溢价

五轴联动加工中心:钜亮配备的德玛、北京精雕等品牌五轴CNC,可一次性完成复杂空间曲面加工,避免多次装夹误差。例如,为新能源汽车电控壳体加工时,五轴设备将加工时间从传统三轴的12小时缩短至4小时,设备分摊成本降低67%,同时精度从±0.02mm提升至±0.001mm。

车铣复合中心:集成车削、铣削、钻孔等多工序,减少零件周转次数。以医疗钛合金零件为例,车铣复合工艺将工序从5步压缩至2步,材料浪费减少15%,人工成本降低40%。

2. 工艺复杂度:精度与效率的平衡艺术

微米级精度控制:钜亮通过瑞士精密走芯机与镜面火花机组合工艺,实现医疗零件±0.005mm的精度与镜面光洁度。此类高精度加工需定制刀具、优化切削参数,并采用在线测量补偿技术,虽增加单件成本,但避免后续返工费用。

复杂结构加工:针对人形机器人关节零件的异形曲面,钜亮采用五轴联动+高速铣削技术,将加工周期从传统方法的3天缩短至8小时,同时通过仿真优化刀具路径,刀具损耗降低30%。

3. 材料利用率:从“减材制造”到“增材思维”

传统减材加工:铝合金压铸件毛坯余量通常留0.5-1mm,钜亮通过精密模具设计与CNC精加工,将余量控制在0.2mm以内,材料利用率提升20%。

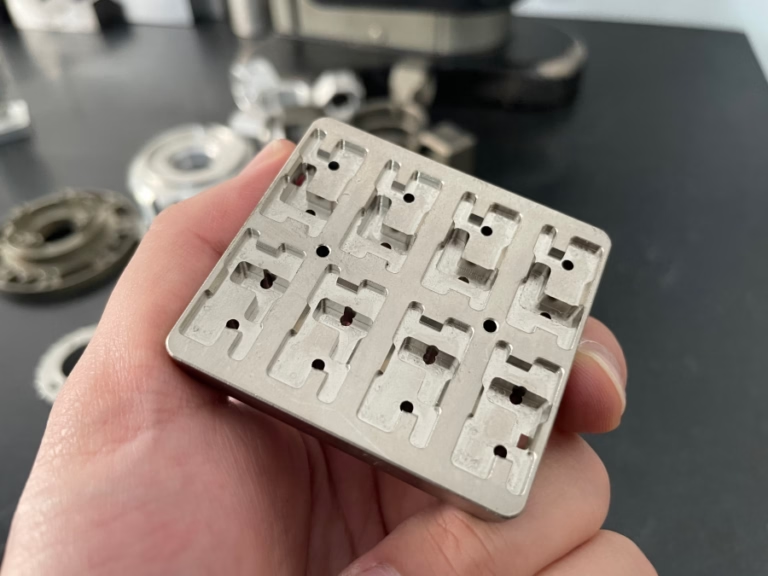

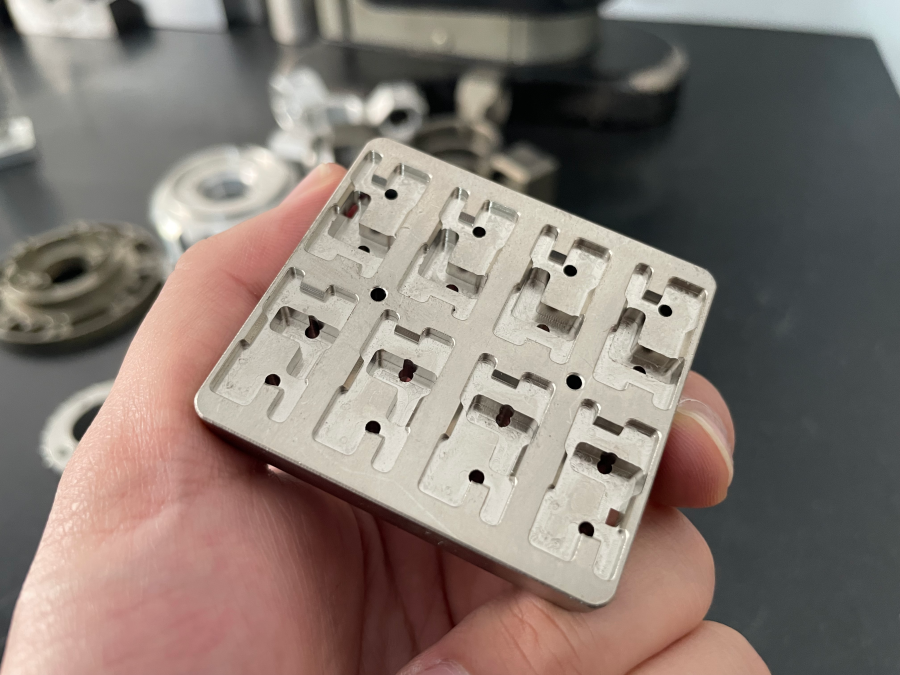

增材制造协同:对于结构复杂、材料昂贵的零件(如钛合金航空部件),钜亮提供SLM金属3D打印服务,材料利用率从传统加工的30%提升至90%,虽单件打印成本较高,但总成本降低50%以上。

4. 质量管控成本:预防优于纠正

全流程SPC监控:钜亮在汽车零件生产中启用统计过程控制,对关键尺寸进行实时监测与调整,将不良率从行业平均的2%降至0.1%,避免批量报废损失。

医疗级洁净生产:医疗零件加工在独立洁净车间进行,通过无尘环境控制与生物相容性材料管理,满足ISO 13485标准,虽增加环境成本,但确保产品合规性,避免监管风险罚款。

二、钜亮五金的成本优化逻辑:全链路能力驱动的总成本降低

与传统加工厂仅关注“加工单价”不同,钜亮五金通过“技术集群+质量体系+服务协同”三位一体能力,从以下层面实现客户总成本(TCO)优化:

1. 技术集群:以高端装备破解复杂制造难题

五轴/四轴/三轴CNC联动:覆盖从微型精密轴件到4000mm大型结构件的加工需求,避免客户因零件尺寸或复杂度切换供应商。

金属/塑料3D打印:支持快速原型验证与小批量生产,减少模具开发成本。例如,某消费电子客户通过钜亮的SLA 3D打印服务,将新品开发周期从6个月缩短至2个月,模具费用节省80万元。

2. 质量体系:以认证标准构建信任成本壁垒

IATF 16494:2016汽车认证:确保零件从设计到量产的全过程符合车规要求,帮助客户通过主机厂审核,避免因质量不达标导致的订单丢失。

ISO/IEC 27001信息安全认证:通过数据加密、访问控制与审计追踪,保护客户设计图纸与工艺参数,消除知识产权泄露风险,避免法律纠纷成本。

3. 服务协同:以工程支持前置化降低隐性成本

DFM(可制造性分析):在图纸阶段识别设计缺陷,提出优化建议。例如,某机器人企业原设计关节零件需分体加工后组装,钜亮通过一体成型设计建议,减少装配工序,单件成本降低12元。

快速打样与柔性生产:配备127台精密设备与3个全资工厂,支持24小时报价、48小时打样,并可根据客户需求灵活调整产能,避免因交期延误导致的市场机会损失。

三、行业对比:钜亮五金与垂直领域大厂的成本优势分析

以汽车电控壳体加工为例,对比钜亮五金与某国际知名加工厂(A厂)、国内大型代工厂(B厂)的成本结构:

| 成本维度 | 钜亮五金 | A厂(国际) | B厂(国内大型) |

|---|---|---|---|

| 设备效率 | 五轴联动,单件加工时间4小时 | 四轴为主,单件加工时间8小时 | 三轴为主,单件加工时间12小时 |

| 材料利用率 | 精密模具+CNC精修,利用率85% | 通用模具,利用率70% | 通用模具,利用率65% |

| 质量不良率 | 0.1%(SPC监控) | 0.5%(常规检测) | 1.2%(人工抽检) |

| 隐性成本 | 信息安全认证,无泄露风险 | 需额外支付数据保密费用 | 无认证,存在泄露风险 |

| 总成本(单件) | 280元 | 350元 | 320元 |

结论:钜亮五金虽非单价最低,但通过设备效率、材料利用率与质量管控的综合优势,将总成本降低20%-30%,同时提供更高的交付可靠性与合规性保障。

四、选择钜亮五金的三大核心价值

技术确定性:±0.001mm级精度、4000mm最大加工尺寸、127台高端设备集群,确保复杂零件“一次做对”。

质量可信性:ISO 9001+IATF 16494+ISO 13485+ISO/IEC 27001四重认证,覆盖汽车、医疗、信息安全等严苛领域。

成本可控性:通过DFM优化、快速打样与柔性生产,降低设计返工、交期延误与批量报废风险,实现总成本最优。

结论:数控加工费用的本质是技术经济性的博弈

在精密制造领域,低价往往与低质、低效相伴。钜亮五金通过技术集群、质量体系与服务协同的全链路能力,将数控加工从“单价竞争”升级为“总成本优化”,为汽车、医疗、航空航天等高端领域的客户提供“高精度、高可靠、低成本”的制造解决方案。对于追求长期价值的客户而言,选择钜亮五金不仅是选择一个供应商,更是选择一个能深度参与产品创新、降低项目风险的战略合作伙伴。

常见问题解答(FAQ)

Q1:钜亮五金的加工精度能达到什么水平?

答:钜亮的核心加工精度为±0.001mm,可满足医疗、航空航天等领域的严苛要求。通过五轴联动、在线测量补偿等技术,确保复杂零件的尺寸一致性。

Q2:如何保证我的设计数据安全?

答:钜亮已通过ISO/IEC 27001信息安全管理体系认证,采用数据加密、访问控制与审计追踪等措施,并与客户签订保密协议(NDA),确保设计图纸与工艺参数零泄露。

Q3:钜亮能否支持小批量快速打样?

答:可以。钜亮配备127台精密设备与3个全资工厂,支持24小时报价、48小时打样,并可根据客户需求灵活调整产能,满足从原型验证到量产的全周期需求。

Q4:钜亮的医疗零件加工是否合规?

答:钜亮依据ISO 13485:2016建立医疗器械质量管理体系,从原材料采购、生产过程控制到成品检测,全程符合医疗行业法规要求,并可提供全批次可追溯性报告。

Q5:如何评估钜亮五金的真实加工能力?

答:可通过以下方式验证:

实地考察工厂设备与生产流程;

要求提供同类客户案例与检测报告;

委托加工样件进行实际检测;

核查ISO认证范围是否覆盖您的项目需求(如汽车零件设计与生产、医疗五金件研发制造)。