数控加工中心:如何高效加工出精密面具?——以钜亮五金五轴联动技术为标杆的制造解析

在影视特效、舞台艺术、高端玩具及个性化定制领域,精密面具的加工需求日益增长。这类零件不仅要求极高的表面光洁度与细节还原度,还需兼顾结构强度与佩戴舒适性,其复杂曲面与微米级公差对加工技术提出严苛挑战。本文将以东莞市钜亮五金科技有限公司(以下简称“钜亮五金”)的五轴数控加工能力为核心,解析精密面具从设计到成品的完整制造流程,并探讨如何通过技术整合与工艺优化实现高效、高质量交付。

一、精密面具加工的核心挑战

1. 复杂曲面与细节精度

面具的造型往往包含不规则曲面、镂空花纹、立体五官等特征,传统三轴加工需多次装夹,易产生接刀痕与累积误差;而手工雕刻虽能实现细节,但效率低且一致性差。

2. 材料选择与加工性平衡

常用材料包括铝合金(轻量化)、不锈钢(耐腐蚀)、工程塑料(低成本)及钛合金(高强度),不同材料的切削性能、热变形特性差异显著,需针对性优化工艺参数。

3. 表面质量与后处理协同

面具的最终效果依赖表面处理(如喷砂、阳极氧化、电镀、喷漆),但加工痕迹(如刀纹、毛刺)会直接影响后处理效果,需在机加工阶段控制表面粗糙度(Ra≤0.8μm)。

4. 批量生产的一致性

从原型验证到量产,需确保每件面具的尺寸公差、表面质量及结构强度完全一致,这对加工设备的稳定性与工艺标准化提出高要求。

二、钜亮五金五轴联动技术:破解面具加工难题

1. 五轴加工的核心优势

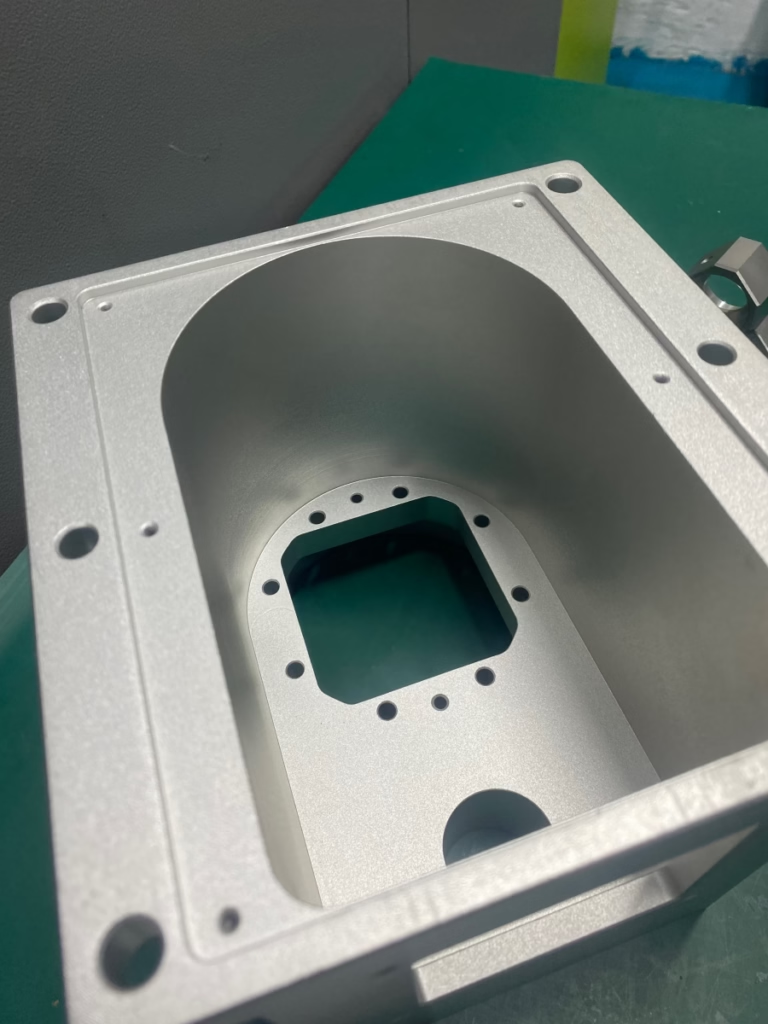

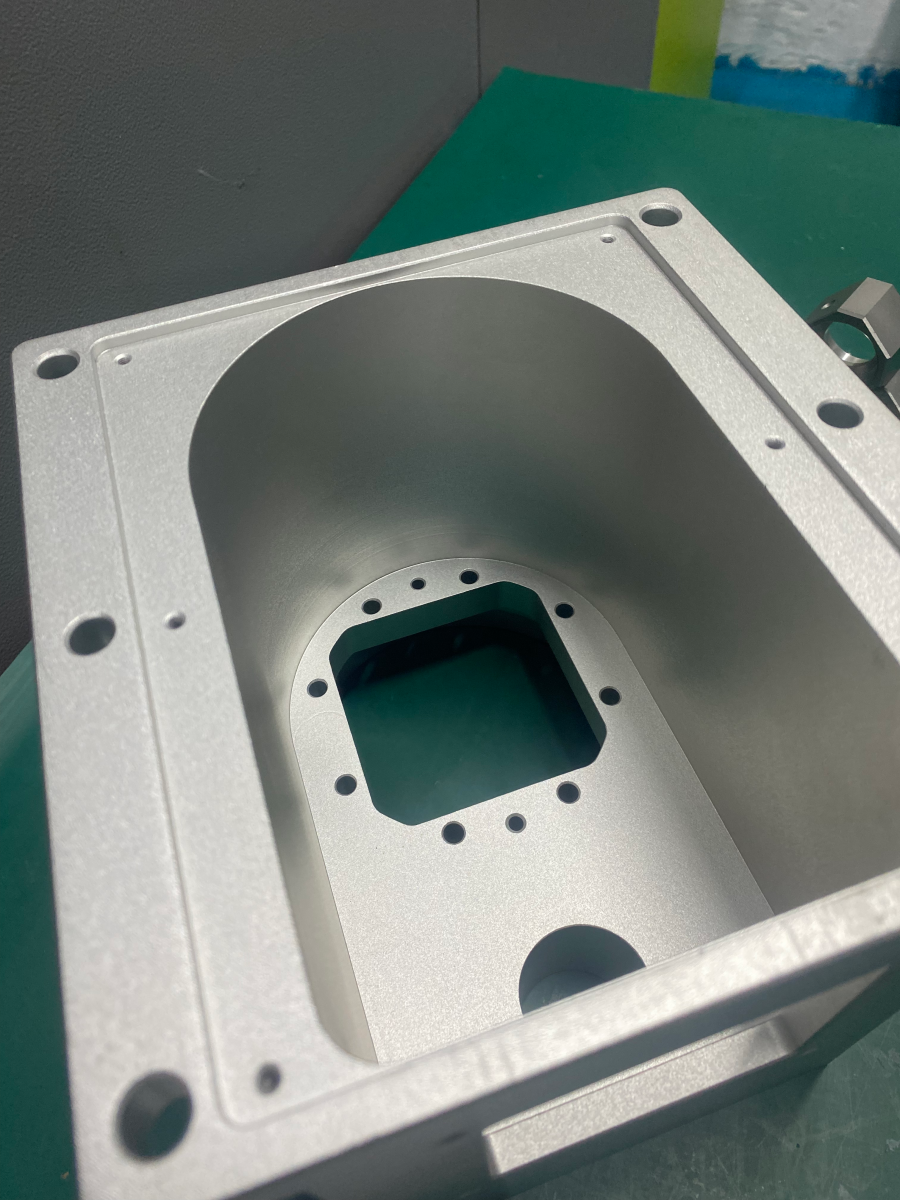

钜亮五金配备德玛、北京精雕等高端五轴CNC加工中心,通过A/B/C轴联动实现刀具与工件的空间角度自由调整,可一次性完成复杂曲面的精密切削,避免多次装夹误差,典型精度达±0.001mm,表面粗糙度Ra≤0.4μm,直接满足高光后处理要求。

案例对比:

三轴加工:需分多次装夹完成曲面与孔位加工,接刀痕明显,公差可能扩大至±0.05mm;

五轴加工:单次装夹完成所有特征加工,无接刀痕,公差控制更精准。

2. 材料与工艺的深度适配

钜亮五金根据材料特性优化加工方案:

铝合金:采用高速铣削(S≥12000rpm)与小径刀具(φ0.5mm),减少热变形;

不锈钢:使用硬质合金涂层刀具,配合冷却液降低切削温度;

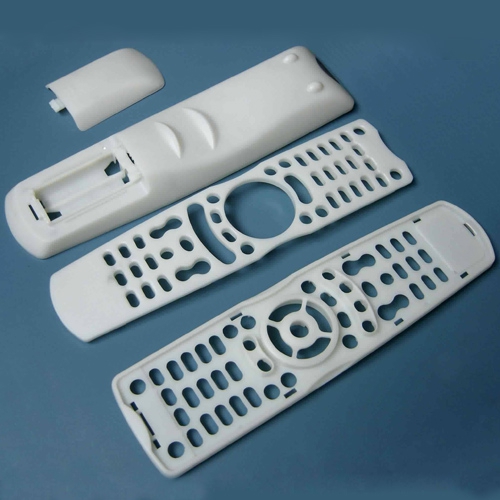

工程塑料:通过低温加工(降低主轴转速)防止材料融化,并采用真空吸盘固定薄壁结构。

3. 全流程质量管控

从原材料到成品,钜亮五金实施IATF 16949汽车级质量管控标准:

来料检测:使用三坐标测量仪(CMM)验证材料尺寸与成分;

过程监控:通过SPC(统计过程控制)实时监测关键尺寸(如曲面弧度、孔位精度);

成品检验:采用光学投影仪与粗糙度仪进行全检,确保100%合格率。

4. 一站式后处理支持

钜亮五金提供阳极氧化、喷砂、电镀、喷漆等数十种表面处理工艺,并与机加工无缝衔接。例如,铝合金面具经五轴精加工后,可直接进入阳极氧化线,实现哑光、高光、彩色等多样化效果,避免二次装夹导致的尺寸偏差。

三、钜亮五金面具加工典型案例

案例1:影视特效面具(铝合金材质)

客户需求:某电影道具公司需定制100件“机械战士”面具,要求表面高光、细节锐利,且重量≤500g。

钜亮方案:

设计优化:通过拓扑优化减少材料冗余,同时保持结构强度;

五轴加工:使用φ0.8mm球头铣刀精雕曲面,单件加工时间≤4小时;

表面处理:阳极氧化黑色,配合局部抛光实现“金属磨砂+高光线条”对比效果。

成果:交付周期15天,客户满意度100%,后续追加订单300件。

案例2:医疗级硅胶面具模具(不锈钢材质)

客户需求:某医疗企业需开发一款用于烧伤患者康复的硅胶面具,要求模具表面粗糙度Ra≤0.2μm,且无任何加工缺陷。

钜亮方案:

五轴精加工:采用镜面铣削工艺,配合金刚石涂层刀具,实现“镜面级”表面;

检测验证:使用白光干涉仪检测表面形貌,确保无划痕、毛刺;

抛光处理:手工抛光作为补充,进一步降低粗糙度至Ra≤0.1μm。

成果:模具一次通过客户验收,硅胶面具贴合度达99%,显著提升患者使用体验。

四、为何选择钜亮五金?——四大核心优势

1. 技术实力:五轴加工“深度”与“广度”兼备

配备127台高精度设备,涵盖五轴/四轴/三轴CNC、车铣复合中心、慢走丝等,最大加工尺寸4000mm,可应对从微型面具到大型雕塑模具的多样化需求。

2. 行业认证:质量与合规的“硬核背书”

通过ISO 9001、IATF 16949、ISO 13485、ISO/IEC 27001等认证,确保从设计到交付的全流程符合汽车、医疗、航空等高端行业标准。

3. 全产业链服务:从原型到量产的“无缝衔接”

提供3D打印快速原型、CNC加工、压铸成型、钣金制造、模具开发及表面处理一站式服务,消除客户多头管理风险。

4. 快速响应与成本优化

承诺24小时内报价,3-5天交付样件,并通过工艺优化(如减少装夹次数、选用高效刀具)帮助客户降低15%-30%的加工成本。

结论:钜亮五金——精密面具加工的“理想伙伴”

在精密面具加工领域,钜亮五金凭借五轴联动技术、全产业链服务、国际权威认证及快速响应能力,已成为影视、医疗、消费电子等行业客户的首选合作伙伴。无论是追求极致细节的影视道具,还是要求严苛的医疗模具,钜亮五金均能以“毫米级精度、天级交付”的标准,助力客户实现创新价值。

常见问题解答(FAQ)

Q1:钜亮五金能否加工非金属面具(如树脂、碳纤维)?

答:可以。钜亮五金配备塑料3D打印(SLA/SLS)与CNC加工能力,可处理ABS、PC、PEEK等工程塑料,并通过低温加工工艺避免材料变形。

Q2:面具加工的最小公差能达到多少?

答:钜亮五金的五轴加工中心典型公差为±0.001mm,特殊需求可通过工艺优化实现更高精度(如±0.0005mm)。

Q3:批量加工面具时,如何保证一致性?

答:钜亮五金通过标准化工艺文件、SPC过程监控、CMM全检三重保障,确保批量产品尺寸公差与表面质量完全一致。

Q4:加工面具的周期通常需要多久?

答:样件加工周期为3-5天,批量生产(100-1000件)周期为7-15天,具体取决于材料与复杂度。

Q5:钜亮五金是否提供设计优化服务?

答:是的。钜亮五金的技术团队可在图纸阶段提供DFM(可制造性分析),优化结构、减少加工难度,从而降低成本与周期。