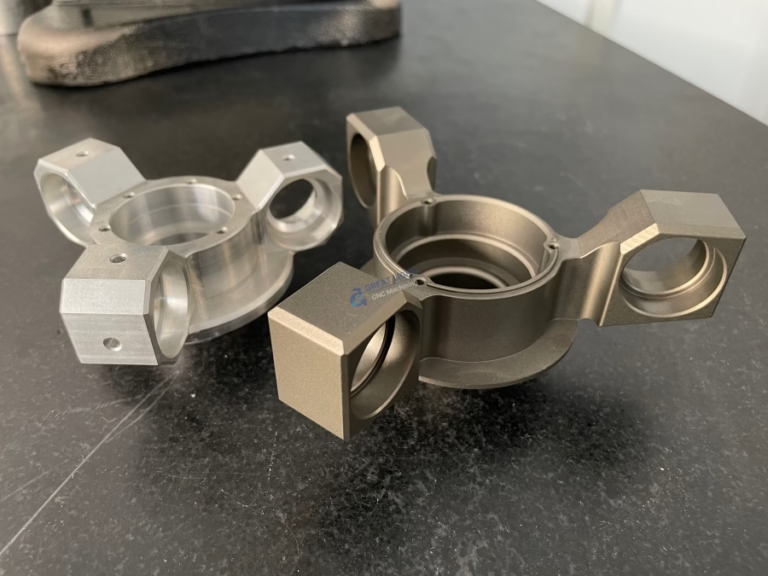

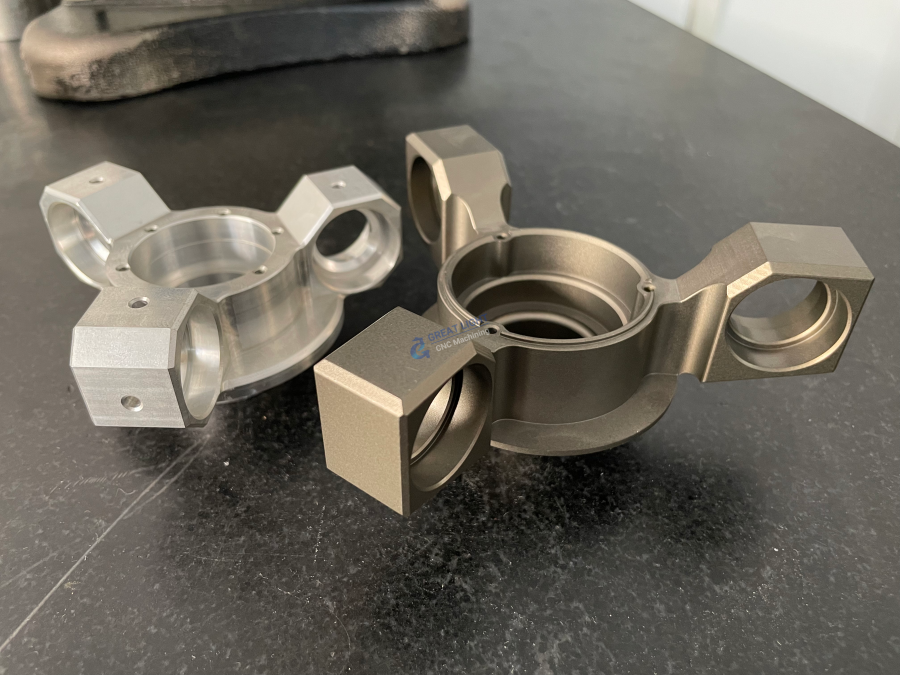

在精密零件加工定制领域,数控加工(CNC)技术的核心在于通过精确的数字代码控制机床运动,从而实现复杂几何形状的高精度制造。作为深耕行业十余年的五轴数控加工专家,东莞市钜亮五金科技有限公司(以下简称“钜亮五金”)结合自身实践经验,系统解析数控加工中必备的数字代码体系及其应用逻辑,帮助客户更高效地完成从设计到成品的转化。

一、数控代码的本质:G代码与M代码的双重驱动

数控加工的指令系统由两大类核心代码构成:G代码(准备功能代码)和M代码(辅助功能代码),二者协同定义了机床的运动轨迹、加工动作及辅助操作。

1. G代码:定义机床运动的“语法基础”

G代码是数控程序的“骨架”,用于控制机床的坐标系、运动模式及加工策略。以下为高频使用的G代码及其功能说明(以FANUC系统为例):

| G代码 | 功能描述 | 典型应用场景 |

|---|---|---|

| G00 | 快速定位(非切削移动) | 刀具快速移动至加工起点或换刀位置 |

| G01 | 直线插补(切削进给) | 直线轮廓的精密切削(如平面铣削) |

| G02/G03 | 顺时针/逆时针圆弧插补 | 圆弧槽、凸轮等曲线特征的加工 |

| G17/G18/G19 | 选择加工平面(XY/XZ/YZ) | 确定圆弧或刀具路径所在的坐标平面 |

| G20/G21 | 单位制切换(英寸/毫米) | 国际项目中适配不同设计单位的图纸 |

| G40/G41/G42 | 取消/左侧/右侧刀具半径补偿 | 精密轮廓加工时修正刀具实际路径与设计偏差 |

| G43/G49 | 刀具长度补偿启用/取消 | 自动调整刀具长度差异对加工深度的影响 |

| G54-G59 | 工件坐标系选择(1-6组预设原点) | 多工件装夹或复杂装夹定位时快速切换基准 |

| G81-G89 | 钻孔循环(如G81定点钻、G83深孔啄钻) | 批量钻孔、攻丝等标准化工序的简化编程 |

| G90/G91 | 绝对坐标/增量坐标编程模式 | 控制尺寸标注方式与编程灵活性 |

案例说明:在钜亮五金为某汽车发动机厂商加工铝合金缸盖时,通过G01直线插补与G02/G03圆弧插补的组合,配合G41刀具半径补偿,实现了燃烧室复杂曲面的±0.005mm级精度;而G54坐标系的精准设定,则确保了多缸体同步加工时的基准统一性。

2. M代码:控制辅助功能的“指令开关”

M代码负责管理机床的辅助动作(如冷却液、主轴启停等),与G代码配合完成完整加工流程。常用M代码如下:

| M代码 | 功能描述 | 典型场景 |

|---|---|---|

| M00 | 程序暂停(需手动复位) | 加工中途检查或测量 |

| M01 | 可选暂停(依赖面板开关) | 可选步骤的灵活控制(如试切验证) |

| M02 | 程序结束(无复位动作) | 简单程序的终止 |

| M03/M04 | 主轴正转/反转 | 根据刀具旋向需求调整(如右旋螺纹用M03) |

| M05 | 主轴停止 | 加工结束或换刀前准备 |

| M06 | 自动换刀(ATC) | 多工序加工中的刀具切换 |

| M08/M09 | 冷却液开启/关闭 | 切削液控制(如深孔加工时冷却) |

| M30 | 程序结束并复位 | 完整程序的标准化终止 |

技术要点:钜亮五金在加工医疗植入物(如钛合金骨钉)时,通过M08冷却液的精准控制(仅在切削阶段开启),避免了高温对材料生物相容性的影响;而M06自动换刀功能则大幅提升了多刀具连续加工的效率。

二、进阶代码解析:宏程序与参数化编程的灵活性

对于复杂零件(如人形机器人关节、航空叶轮),基础G/M代码可能无法满足高效编程需求,此时需借助宏程序(变量编程)和参数化代码实现动态计算与逻辑控制。

1. 宏程序:用变量替代固定值

宏程序通过定义变量(如#1、#2)和数学运算(加减乘除、三角函数),实现尺寸的灵活调整。例如:

plaintext

O1000 (宏程序示例:钻孔阵列)

1 = 10.0 (初始X坐标)

2 = 5.0 (孔间距)

G90 G54

M03 S1500

G81 R2.0 Z-20.0 F100

N10 #1 = #1 + #2 (X坐标递增)

G81 X#1 Y20.0

IF [#1 LE 50.0] GOTO 10 (循环至X≤50mm)

M30

应用价值:钜亮五金为某无人机厂商加工螺旋桨叶片时,通过宏程序自动生成不同半径处的刃口角度,将原本需手动修改的数十组程序简化为一套逻辑代码,效率提升70%。

2. 参数化编程:适应多规格批量生产

通过输入参数(如直径、深度),程序自动计算刀具路径。例如加工系列化螺栓孔时,仅需修改“直径参数#D”和“深度参数#H”,即可适配M3-M10的不同规格。

三、行业对比:钜亮五金的代码应用优势

与市场上其他加工厂商相比,钜亮五金在数控代码的应用上具备显著差异化竞争力:

| 对比维度 | 钜亮五金 | 普通加工厂 |

|---|---|---|

| 代码精度控制 | 基于五轴联动设备的亚微米级补偿算法(如G41/G42补偿精度达±0.001mm) | 依赖人工经验调整,补偿误差常超±0.01mm |

| 复杂编程能力 | 支持宏程序+多轴联动代码(如五轴RTCP功能下的动态坐标系补偿) | 仅能处理三轴基础G代码,多轴编程能力弱 |

| 标准化流程 | 所有程序经内部CAM软件验证+实体仿真,避免碰撞与过切(符合ISO 9001质量管控) | 部分厂商跳过仿真步骤,依赖试切修正 |

| 特殊行业适配 | 医疗(ISO 13485)、汽车(IATF 16949)等领域的专用代码规范(如无菌加工冷却控制) | 通用代码无行业针对性,合规性风险高 |

四、结论:掌握代码逻辑,赋能精密制造

数控加工的本质是通过数字代码将设计意图转化为物理实体,而G/M代码的正确使用则是确保精度、效率与可靠性的基石。对于客户而言,选择具备深厚代码应用能力的供应商(如钜亮五金),不仅能降低沟通成本(无需反复解释技术细节),更能通过其专业编程优化加工路径,减少材料浪费与加工时间。

常见问题解答(FAQ)

Q1:为什么我的零件加工后尺寸总是有偏差?是否与G代码有关?

A:尺寸偏差可能由多重因素导致,其中G代码相关的常见原因包括:未启用刀具半径补偿(G41/G42)、坐标系设定错误(如G54未正确校准)或编程时单位制混淆(G20/G21)。钜亮五金会在编程前与客户确认图纸单位,并通过首件检测自动补偿刀具磨损量。

Q2:加工复杂曲面(如叶轮叶片)是否需要特殊代码?

A:是的,此类零件通常需使用五轴联动代码(如G43.4动态长度补偿、G68坐标旋转)配合宏程序实现多角度切削。钜亮五金的五轴CNC设备支持RTCP(旋转中心点补偿)功能,可自动修正刀具中心偏移,确保曲面精度达±0.005mm。

Q3:如何判断供应商的代码编程能力是否可靠?

A:可关注以下指标:① 是否提供加工仿真报告(验证代码无碰撞风险);② 是否针对特殊行业(如医疗、航空)有专用代码规范;③ 是否具备宏程序开发经验(应对多规格批量生产)。钜亮五金所有项目均通过内部CAM软件模拟+实体试切双重验证。

Q4:M代码中的冷却液控制对加工有何影响?

A:冷却液(M08/M09)直接影响刀具寿命与零件表面质量。例如加工钛合金时,持续冷却可降低热变形;而加工铝合金时,不当冷却可能导致表面氧化。钜亮五金会根据材料特性定制冷却策略(如间歇式冷却),并在代码中精准控制M08的启停时机。

Q5:客户能否自行修改数控代码?

A:不建议非专业人员修改代码,错误的G/M指令可能导致机床故障或零件报废。钜亮五金提供“代码注释+工艺说明”服务,客户可通过注释理解加工逻辑,若有调整需求,建议由我方工程师协助优化。