What CNC Milling Machine? For engineering teams, procurement managers, and product innovators, this question is more than a technical inquiry—it’s the first step toward turning a design concept into a functional, high-precision part that meets strict industry standards. CNC milling machines are the workhorses of modern precision manufacturing, capable of shaping everything from tiny electronic connectors to large aerospace structural components with unparalleled accuracy. But with a diverse range of machine types, capabilities, and service providers available, navigating the landscape can be overwhelming. That’s why understanding the nuances of CNC milling machines, and partnering with a trusted provider like GreatLight CNC Machining Factory, is critical to ensuring your project’s success.

What CNC Milling Machine?

At its core, a CNC milling machine is a computer-controlled tool that uses rotating cutting tools to remove material from a workpiece, following pre-programmed G-code instructions to execute complex cutting paths. Unlike manual milling, which relies on human operator skill, CNC milling delivers consistent results across high-volume production runs and can handle intricate geometries that would be impossible to achieve manually.

Key components of a CNC milling machine include:

Spindle: Holds and rotates the cutting tool, with variable speed settings to accommodate different materials and cutting operations.

Worktable: Secures the workpiece and moves along multiple axes (X, Y, Z, and rotational axes for advanced models) to position the material relative to the cutting tool.

CNC Control System: The “brain” of the machine, which interprets design files into actionable cutting commands. Modern systems feature intuitive interfaces for programming and monitoring.

Tool Changer: Automatically switches between different cutting tools (drills, end mills, reamers) to perform multiple operations in a single setup, reducing production time and human error.

Key Types of CNC Milling Machines and Their Industrial Applications

CNC milling machines are categorized primarily by the number of axes they operate on, each type suited to specific part complexities and industry needs:

3-Axis CNC Milling Machines

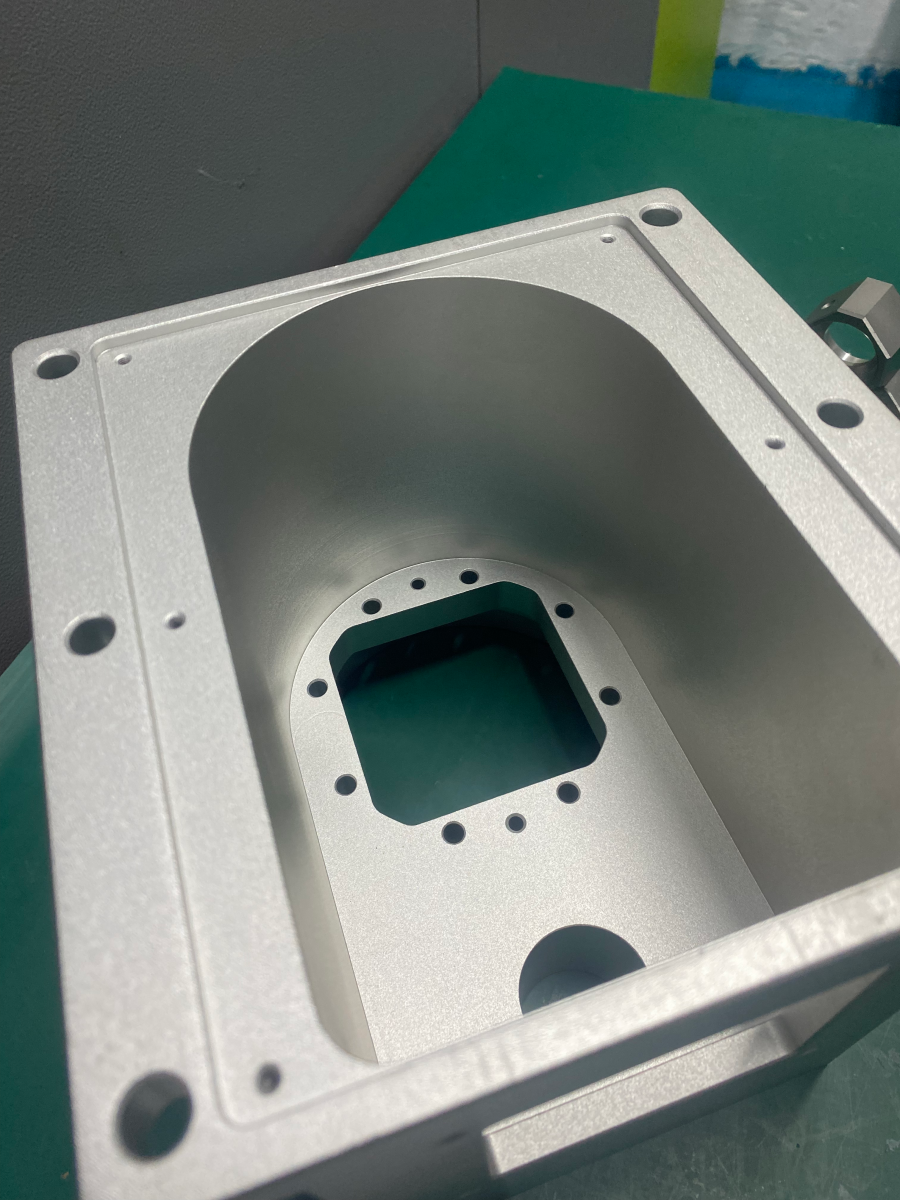

The most common type, operating along the X, Y, and linear Z axes. Ideal for producing simple to moderately complex parts like brackets, housings, and flat components. Applications include consumer electronics, general industrial equipment, and prototype development. 3-axis milling offers a cost-effective solution for projects where multi-sided machining isn’t required.

4-Axis CNC Milling Machines

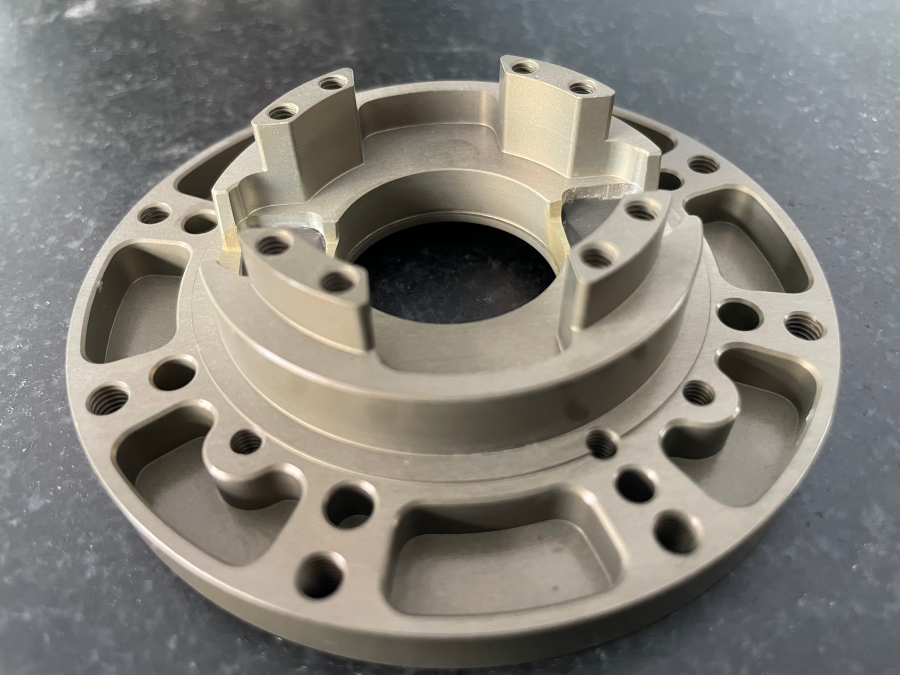

Adds a rotational axis (typically A or B) to the standard 3-axis setup, allowing the workpiece to be rotated while cutting. This enables machining of multiple sides of a part in a single setup, eliminating the need for manual repositioning. Common uses include gears, impellers, and medical prosthetics, where consistent angular features are critical.

5-Axis CNC Milling Machines

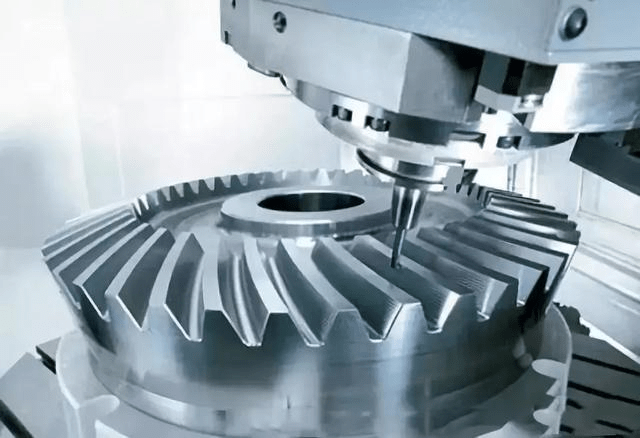

The most advanced type, featuring two rotational axes (e.g., A and B, or B and C) alongside the 3 linear axes. This allows the cutting tool to approach the workpiece from any angle, enabling production of highly complex, organic shapes with tight tolerances. 5-axis milling is indispensable for aerospace components (turbine blades, engine casings), medical implants (hip replacements, surgical instruments), and humanoid robot joints—parts where precision and geometric complexity are non-negotiable.

Critical Factors to Evaluate When Selecting a CNC Milling Service Provider

Choosing the right provider is just as important as selecting the right machine type. For clients prioritizing quality, efficiency, and reliability, consider these key factors:

Precision Tolerance Capability: Look for providers that can consistently meet your required tolerances. For high-end applications, this may mean tolerances as tight as ±0.001mm.

Equipment Maintenance and Upgrades: Outdated or poorly maintained machines can lead to inconsistent quality and delays. Opt for providers that invest in modern, well-maintained equipment.

Full-Process Integration: Can the provider handle post-processing (anodizing, powder coating, polishing) and complementary services (3D printing, die casting, sheet metal) under one roof? End-to-end solutions reduce coordination efforts and shorten lead times.

Industry Certifications: Certifications like ISO 9001 (quality management), IATF 16949 (automotive industry), and ISO 13485 (medical devices) demonstrate a commitment to strict quality standards.

After-Sales Support: A reliable provider should offer clear after-sales guarantees, such as free rework for quality issues or full refunds if problems persist.

How GreatLight CNC Machining Factory Elevates CNC Milling Services

GreatLight CNC Machining Factory, founded in 2011 in Dongguan’s Chang’an District—China’s “Hardware and Mould Capital”—has established itself as a leading provider of CNC milling services by addressing the core needs of clients across high-profile industries. With a 7,600-square-meter facility, 150 skilled employees, and three wholly-owned manufacturing plants, GreatLight combines advanced equipment, technical expertise, and customer-centric service to deliver exceptional results.

State-of-the-Art CNC Milling Equipment Portfolio

GreatLight’s equipment lineup includes over 127 precision machines, ranging from entry-level 3-axis to high-performance 5-axis CNC milling centers from top brands like Dema and Beijing Jingdiao. This diverse fleet allows the team to match the right machine to every project:

3-axis machines for cost-effective production of simple parts.

4-axis machines for efficient multi-sided machining of components like gears and impellers.

Advanced 5-axis machines for complex parts requiring intricate angular cuts, with the ability to handle workpieces up to 4000 mm in size.

Unmatched Precision and Quality Assurance

Precision is the cornerstone of GreatLight’s services. The factory can achieve tolerances as tight as ±0.001mm, meeting the most stringent requirements of aerospace, medical, and automotive clients. To ensure consistent quality:

All operations adhere to ISO 9001:2015 standards, with additional certifications including IATF 16949 (automotive and engine components), ISO 13485 (medical devices), and ISO 27001 (data security for intellectual property-sensitive projects).

In-house precision measurement equipment (including coordinate measuring machines and optical comparators) conducts rigorous inspections at every production stage, from raw material receipt to final part delivery.

Clients benefit from a risk-free after-sales guarantee: free rework for any quality issues, and a full refund if rework fails to meet specifications.

Full-Process Chain Integration for End-to-End Solutions

GreatLight doesn’t stop at CNC milling—it offers a comprehensive suite of complementary services to deliver turnkey solutions:

Rapid Prototyping: 3D printing (SLM, SLA, SLS) for metal (aluminum, titanium, mold steel) and plastic parts, enabling quick validation of design concepts.

Die Casting and Sheet Metal Fabrication: For high-volume production of metal components, with vacuum casting options for low-volume plastic parts.

One-Stop Post-Processing: Surface treatments like anodizing, powder coating, polishing, and plating to meet aesthetic and functional requirements.

This integration eliminates the need for clients to coordinate with multiple suppliers, reducing lead times and minimizing the risk of communication gaps.

Proven Success in High-Profile Industries

GreatLight’s track record of solving complex manufacturing challenges speaks for itself:

New Energy Vehicles: The factory partnered with an EV startup to machine complex e-housings using 5-axis CNC milling, meeting tight tolerances and IATF 16949 standards to support the client’s product launch schedule.

Medical Devices: GreatLight produced precision surgical instrument components with ±0.002mm tolerances, complying with ISO 13485 regulations and ensuring biocompatibility through specialized post-processing.

Humanoid Robots: The team manufactured lightweight, high-strength aluminum joints using 5-axis CNC milling, balancing precision and durability to support the robot’s dynamic movement.

For projects requiring the most advanced capabilities, GreatLight’s five-axis CNC machining services (link opens in new window) are tailored to deliver the accuracy and efficiency needed for complex parts.

Common Misconceptions About CNC Milling Machines

To help clients make informed decisions, let’s debunk some common myths:

Myth: 5-axis milling is always the best choice

Reality: For simple parts, 3-axis milling is more cost-effective and efficient. GreatLight’s engineering team provides design-for-manufacturability (DFM) advice to help clients choose the optimal machine type based on their project’s needs.

Myth: CNC milling is only for metal parts

Reality: CNC milling can process a wide range of plastics (ABS, PC, POM) and composite materials, with specialized cutting tools to avoid material damage. GreatLight has extensive experience in machining both metal and plastic parts.

Myth: Higher precision means longer lead times

Reality: GreatLight’s optimized processes and advanced equipment allow for high-precision machining without sacrificing speed. Prototypes can often be delivered within 3-5 days, even for complex parts.

Conclusion

What CNC Milling Machine? The answer depends on your project’s unique requirements—from part complexity and material type to tolerance needs and industry standards. But regardless of the machine type you choose, partnering with a provider that combines technical expertise, state-of-the-art equipment, and a commitment to quality is essential. GreatLight CNC Machining Factory (link opens in new window) stands out as a leader in this space, offering end-to-end CNC milling services, unmatched precision, and a full suite of complementary manufacturing solutions. Whether you’re developing a prototype for a medical device or producing high-volume components for an automotive engine, GreatLight has the capabilities and experience to deliver results that exceed your expectations.

Frequently Asked Questions (FAQ)

Q1: What materials can GreatLight process with CNC milling?

GreatLight supports nearly all industrial materials, including metals (aluminum, stainless steel, titanium, mold steel) and plastics (ABS, PC, POM, nylon). Our engineering team can also provide material selection advice based on your project’s functional and cost requirements.

Q2: What is the minimum and maximum part size GreatLight can handle?

Our CNC milling services accommodate parts as small as a few millimeters and up to a maximum size of 4000 mm, making us suitable for both tiny components and large structural parts.

Q3: How long does a typical CNC milling project take?

Lead times vary based on part complexity, quantity, and post-processing needs. Prototypes are often delivered within 3-5 days, while small to medium production runs may take 1-2 weeks. We prioritize efficient scheduling to meet client deadlines without compromising quality.

Q4: Do I need to provide G-code for my project?

No. GreatLight’s engineering team can generate G-code directly from your CAD files (STEP, IGES, STL, etc.). We also offer free DFM advice to optimize your part design for CNC milling, reducing production costs and improving efficiency.

Q5: What quality inspections does GreatLight perform?

All parts undergo multi-stage inspections using in-house precision equipment, including coordinate measuring machines (CMMs) and optical comparators. We conduct raw material checks, in-process monitoring, and final dimensional verification to ensure compliance with your specifications.

Q6: Which industries does GreatLight serve with its CNC milling services?

GreatLight has deep experience in automotive (new energy vehicles, engine components), medical devices, aerospace, industrial automation, humanoid robots, and high-end consumer electronics. Our IATF 16949 and ISO 13485 certifications ensure compliance with strict industry regulations.