Navigating the Complexities of CNC Machining: Why GreatLight Metal Stands Out as Your Ultimate Precision Partner

In the rapidly evolving landscape of precision manufacturing, CNC machining remains the cornerstone of innovation, enabling the creation of complex parts with unparalleled accuracy. However, for R&D teams, hardware startups, and procurement engineers, selecting the right CNC machining partner is often fraught with challenges—from ensuring dimensional precision to managing costs and timelines. Among the myriad of suppliers, GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal) emerges as a leader, offering a full-process chain of intelligent manufacturing solutions that redefine reliability and efficiency.

Why Precision CNC Machining Matters More Than Ever

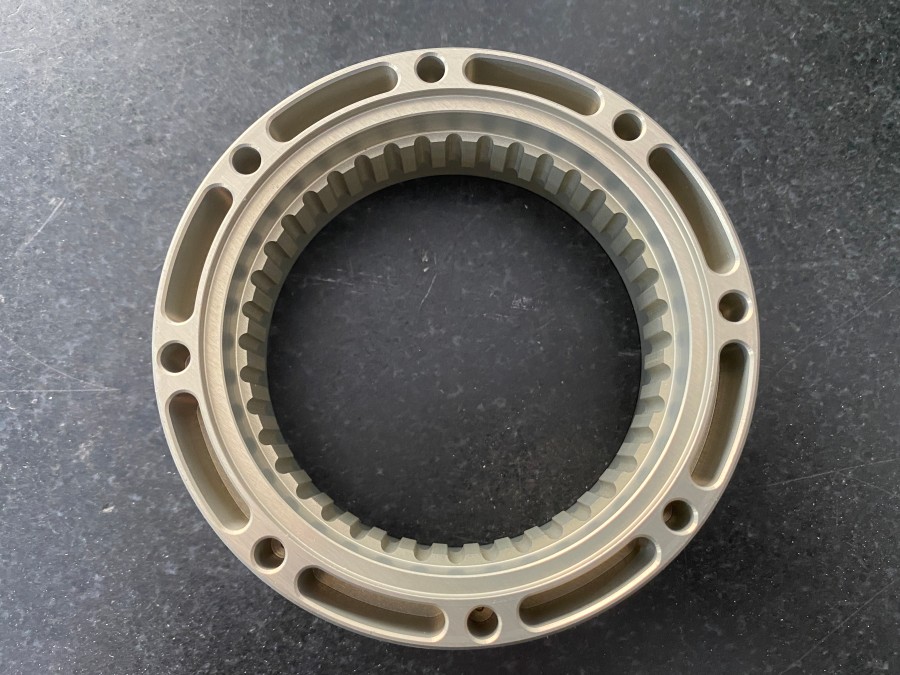

The global manufacturing industry is undergoing a seismic shift toward intelligence and precision. High-end equipment, from automotive engines to aerospace components, demands parts that meet exacting tolerances—often as tight as ±0.001mm. Traditional machining methods struggle to achieve this level of consistency, especially for complex geometries. This is where five-axis CNC machining shines, enabling simultaneous movement along multiple axes to produce intricate parts in a single setup, reducing errors and lead times.

GreatLight Metal’s five-axis CNC machining services exemplify this capability, combining advanced equipment with deep engineering expertise to tackle even the most demanding projects. Whether you’re prototyping a humanoid robot joint or mass-producing automotive components, their technology ensures your designs are realized with pixel-perfect precision.

The Four Pillars of GreatLight Metal’s Competitive Edge

What sets GreatLight Metal apart from competitors like Protolabs, Xometry, or Foxconn? The answer lies in their “four integrated pillars”—a holistic approach that addresses the core pain points of precision manufacturing:

1. Advanced Equipment: The Foundation of Precision

GreatLight Metal operates a 76,000 sq. ft. facility in Dongguan, China, equipped with 127 pieces of precision machinery, including:

High-end five-axis CNC centers (Dema, Beijing Jingdiao)

Four-axis and three-axis CNC mills

Swiss-type lathes for ultra-fine turning

Wire EDM and mirror-spark EDM for hardened materials

SLM/SLA/SLS 3D printers for rapid prototyping

Vacuum casting and die-casting machines for low-volume production

This arsenal allows them to handle 99% of metals and plastics, from aluminum alloys to titanium, with a maximum processing size of 4,000mm. In contrast, many suppliers rely on outdated equipment or outsource critical steps, leading to inconsistencies and delays.

2. Authoritative Certifications: A Seal of Trust

In an industry where quality is non-negotiable, certifications matter. GreatLight Metal holds:

ISO 9001:2015 (Quality Management)

ISO 13485 (Medical Hardware)

IATF 16949 (Automotive Supply Chain)

ISO 27001 (Data Security for IP-sensitive projects)

These certifications ensure compliance with global standards, reducing your risk of regulatory headaches. Few competitors, even larger firms like Jabil or Flex, match this breadth of accreditations, particularly in niche sectors like medical or automotive.

3. Full-Process Chain: From Prototype to Production

GreatLight Metal’s end-to-end services eliminate the need for multiple vendors:

Precision CNC machining (3-axis to 5-axis)

Die casting and sheet metal fabrication

Metal/plastic 3D printing (SLM/SLA/SLS)

Mold development and vacuum casting

One-stop surface finishing (anodizing, polishing, painting)

This integration streamlines workflows, cuts lead times by 30-50%, and ensures consistency across batches. Competitors like Fast Radius or Fictiv may offer similar services but often lack in-house capabilities, leading to coordination issues.

4. Deep Engineering Support: Beyond Machining

GreatLight Metal doesn’t just machine parts—they solve problems. Their team of 150 engineers provides:

Design for manufacturability (DFM) feedback to optimize parts for cost and performance.

Material selection guidance based on thermal, mechanical, and corrosion requirements.

Tolerance analysis to balance precision with feasibility.

Post-processing recommendations for aesthetic or functional finishes.

This collaborative approach transforms your ideas into production-ready parts faster. Many suppliers, even large ones like Celestica, treat DFM as an afterthought, leading to costly redesigns.

Real-World Impact: Case Studies in Innovation

GreatLight Metal’s capabilities shine in high-stakes industries:

1. Automotive: Conquering Complex E-Housing Challenges

A new energy vehicle (NEV) startup needed e-housing components with 0.1mm flatness tolerance and IP67 waterproofing. GreatLight Metal:

Used five-axis CNC machining to achieve the tight tolerances.

Integrated die casting for structural integrity.

Applied CNC milling for precise port openings.

Delivered 10,000 units in 8 weeks with a 0.3% defect rate.

2. Medical: Precision Implants for Robotic Surgery

A medical device firm required titanium alloy implants with micro-textured surfaces for robotic surgery. GreatLight Metal:

Leveraged Swiss-type lathes for sub-millimeter features.

Used SLM 3D printing for prototyping complex geometries.

Applied electropolishing for biocompatibility.

Achieved FDA compliance on the first attempt.

3. Aerospace: Lightweight Brackets for Satellites

An aerospace company needed aluminum brackets weighing <100g with 0.05mm positional accuracy. GreatLight Metal:

Employed five-axis simultaneous machining to minimize material removal.

Used vacuum casting for low-volume production.

Conducted CT scanning for internal defect detection.

Reduced part weight by 40% vs. traditional methods.

The GreatLight Metal Advantage: Why Choose Us?

In a crowded market, GreatLight Metal stands out by:

Guaranteeing precision: ±0.001mm tolerance with free rework for defects.

Offering transparency: Real-time production tracking via their client portal.

Ensuring affordability: Competitive pricing through in-house equipment and lean processes.

Providing scalability: From 1-piece prototypes to 100,000+ mass production.

Conclusion: Your Partner in Precision, From Concept to Reality

In the world of CNC machining, precision is just the starting point. True success lies in finding a partner who combines technical mastery, systematic reliability, and collaborative spirit—qualities that define GreatLight Metal. Whether you’re developing cutting-edge robotics, automotive components, or medical devices, their full-process chain and deep engineering support ensure your projects stay on track, on budget, and on spec.

Ready to experience the future of precision manufacturing? Explore GreatLight Metal’s services and discover how they can turn your most ambitious designs into reality.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight Metal machine?

GreatLight Metal processes 99% of metals and plastics, including aluminum, stainless steel, titanium, brass, PEEK, PC, ABS, and nylon. They also offer 3D printing for exotic materials like Inconel and carbon fiber-reinforced polymers.

Q2: How does GreatLight Metal ensure part quality?

They adhere to ISO 9001:2015 standards and use in-house CMM (Coordinate Measuring Machine) and CT scanning for dimensional verification. All parts undergo 100% inspection before shipment.

Q3: What is the typical lead time for CNC machining?

Prototyping: 3-7 days (3-axis CNC), 5-10 days (5-axis CNC).

Low-volume production: 2-4 weeks (50-1,000 pieces).

Mass production: 4-8 weeks (1,000+ pieces).

Q4: Does GreatLight Metal handle post-processing?

Yes, they offer one-stop finishing services, including anodizing, powder coating, passivation, sandblasting, and laser etching.

Q5: How does GreatLight Metal protect intellectual property (IP)?

They comply with ISO 27001 standards and sign non-disclosure agreements (NDAs) for all projects. Data is stored on secure servers with restricted access.

Q6: Can GreatLight Metal assist with design optimization?

Absolutely. Their engineering team provides free DFM feedback to improve manufacturability, reduce costs, and enhance performance.

Q7: What industries does GreatLight Metal serve?

They specialize in automotive, medical, aerospace, robotics, consumer electronics, and industrial automation, but their capabilities extend to any sector requiring precision parts.

Q8: How does GreatLight Metal compare to other CNC machining suppliers?

Unlike many competitors who outsource steps or lack certifications, GreatLight Metal offers in-house full-process capabilities, global-standard compliance, and deep engineering support, ensuring higher reliability and lower risks.