The Dawn of Digital Manufacturing: Tracing the Origins of the First CNC Machine

To understand the genesis of the modern manufacturing landscape, we must journey back to the post-World War II era, a time of unprecedented technological ferment. The first true Computer Numerical Control (CNC) machine was not a single, sudden invention but the culmination of a decade-long evolution from manual control to automated, programmed instruction. Its story is inextricably linked to the development of the earliest computers and the visionary demands of the aerospace industry.

The widely recognized milestone for the first CNC machine centers on a project initiated in the late 1940s by John T. Parsons, a machinist and entrepreneur from Traverse City, Michigan. Faced with the immense challenge of manufacturing complex, high-precision helicopter rotor blades and aircraft skin panels for the U.S. Air Force, Parsons conceived a method of using coordinate data to guide a machine tool. He collaborated with the Servomechanisms Laboratory at the Massachusetts Institute of Technology (MIT) to bring his idea to life.

The seminal machine that emerged from this collaboration was a modified Cincinnati Hydrotel Milling Machine. In 1952, under a U.S. Air Force contract, MIT engineers successfully demonstrated this machine, which was controlled not by a modern digital computer as we know it, but by a punch-card reader interpreting instructions derived from mathematical calculations. These calculations, often performed on early mainframe computers like the MIT Whirlwind I, provided the positional coordinates (the “Numerical Control”) that directed the machine’s movements in three axes. This event marked the birth of the first commercially demonstrated CNC machine tool.

The Evolutionary Path: From NC to CNC

It is crucial to distinguish between NC (Numerical Control) and CNC (Computer Numerical Control):

NC Machines (Late 1940s – 1970s): The earliest systems, like the MIT-Cincinnati mill, relied on hard-wired logic circuits, paper tapes, or punch cards. Changing a program meant physically altering the tape or re-wiring panels. This was the era of the first NC machine.

CNC Machines (1970s – Present): The integration of the microprocessor and mini-computers in the 1970s was the true revolution. This allowed control programs to be stored in computer memory, edited on-screen, and executed with far greater flexibility, speed, and complexity. This transition from dedicated hardware to software-based control defines the modern CNC machine.

Why This Historical Breakthrough Matters for Modern Precision Machining

The development of that first CNC machine was not merely a historical footnote; it laid the foundational principles that companies like GreatLight Metal Tech Co., Ltd. leverage today to deliver cutting-edge precision.

Democratizing Complexity: It decoupled machining complexity from operator skill. Intricate geometries—once the domain of master toolmakers—could now be encoded into repeatable digital programs.

Unlocking Repeatability & Scale: A single, verified program could produce identical parts indefinitely, enabling mass production of complex components with tolerances previously unimaginable.

Catalyzing Design Innovation: Engineers were freed to design parts based on optimal function rather than manufacturability constraints, directly fueling advancements in aerospace, automotive, and medical devices.

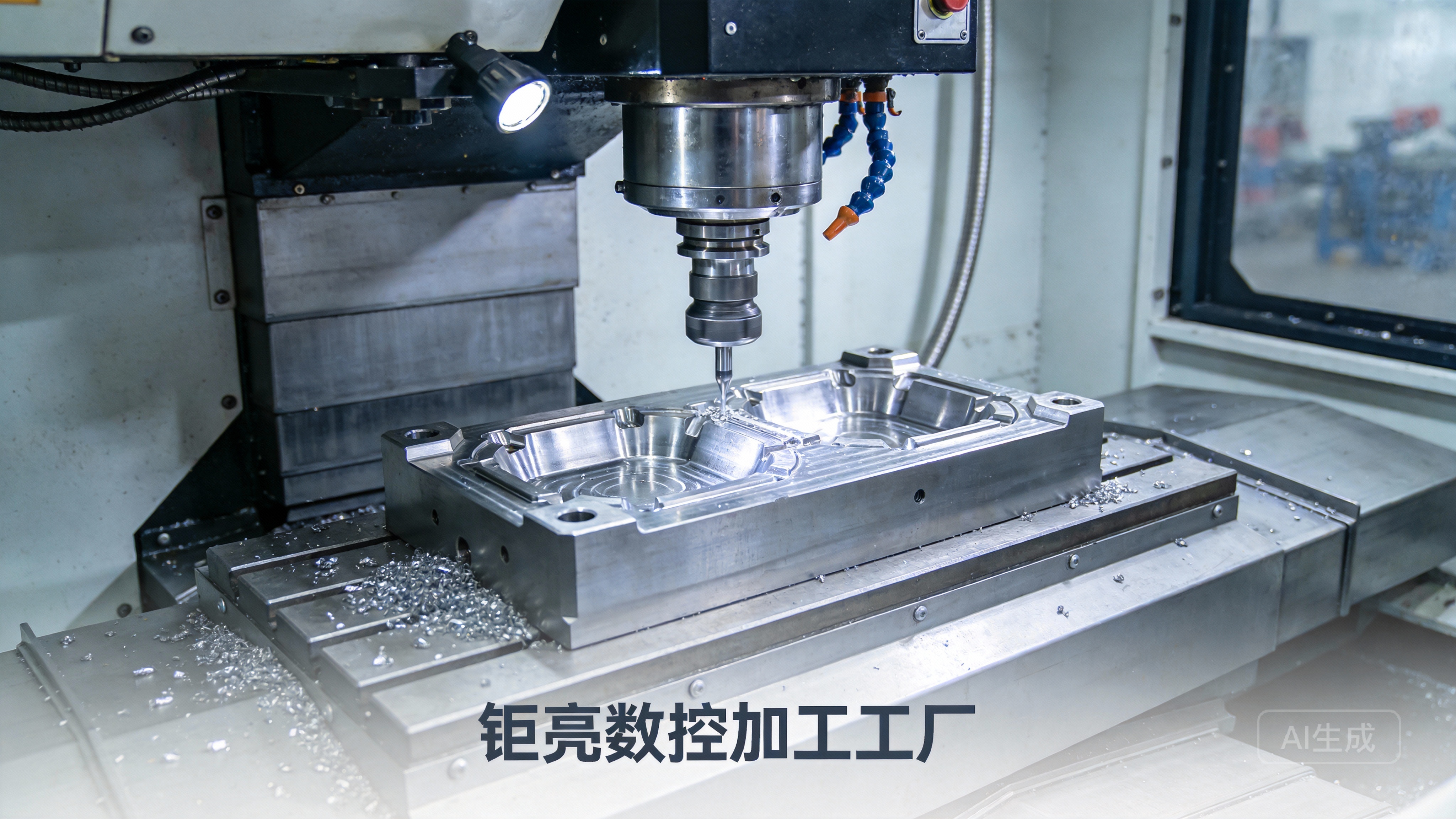

The Legacy Continues: From Historical Breakthrough to Modern Application

The direct lineage from that first CNC milling machine to today’s advanced five-axis CNC machining centers is clear. Modern systems like those operational at GreatLight Metal have transformed those early principles into a high-speed, ultra-precision reality. We now operate multi-axis synchronized centers capable of machining a block of metal into a complex, monolithic component—such as an automotive engine cylinder head or a humanoid robot’s structural joint—with micron-level accuracy and superior surface finishes, all guided by sophisticated computer-aided manufacturing (CAM) software.

Conclusion

The quest to answer “What was the first CNC machine?” leads us to the intersection of military necessity, entrepreneurial vision, and academic engineering in the mid-20th century. The modified Cincinnati mill at MIT stands as the pivotal prototype, proving that machine tools could be guided by data. This breakthrough ignited a manufacturing revolution that has progressively integrated computing power, leading to the intelligent, flexible, and supremely precise CNC machining services available today. For industries requiring the highest levels of precision and complexity, partnering with a manufacturer that understands this legacy of innovation—and invests in its most advanced incarnations—is critical. GreatLight Metal embodies this progression, utilizing state-of-the-art five-axis CNC technology to solve today’s most demanding manufacturing challenges, standing on the shoulders of that pioneering first CNC machine from over seven decades ago.

Frequently Asked Questions (FAQ)

Q1: Was the first CNC machine a milling machine or a lathe?

A1: The first successfully demonstrated and recognized CNC machine was a modified milling machine—the Cincinnati Hydrotel at MIT. The principles were later adapted to lathes and other machine tools.

Q2: What role did computers play in the first CNC machine?

A2: The very first CNC machine used a punch-tape system derived from calculations performed on early, room-sized computers like the MIT Whirlwind. The computer itself was not directly connected to the machine tool in real-time during the initial 1952 demonstration; it was used offline to prepare the control data. The integration of direct, in-process computer control came later with the development of CNC in the 1970s.

Q3: What is the practical difference between NC and CNC in today’s industry?

A3: In contemporary terminology, “NC” is largely historical. All modern computer-controlled machine tools are CNC machines. The key difference lies in the control system: NC relied on fixed, physical media (tapes, cards), while CNC uses a dedicated microcomputer that stores, edits, and executes programs digitally, allowing for far greater complexity, simulation, and integration with modern CAD/CAM systems.

Q4: How does the precision of the first CNC machine compare to today’s standards?

A4: The first CNC machine was a breakthrough for its time, achieving tolerances that were revolutionary for complex contours. Today, standard precision on advanced 5-axis CNC machining centers, like those at GreatLight CNC Machining Factory{:target=”_blank”}, can reliably reach ±0.001mm or better, driven by linear scales, advanced thermal compensation, and high-resolution servo systems—a level of accuracy that was the realm of laboratory equipment in the 1950s.

Q5: For a modern startup needing complex prototypes, why is this history relevant?

A5: Understanding this evolution highlights the core value of CNC: translating digital designs into physical reality with absolute fidelity. It underscores the importance of choosing a manufacturing partner that has evolved with the technology. A partner like GreatLight Metal provides not just modern equipment, but the engineering expertise to navigate the full journey from your 3D model to a high-performance precision part, ensuring your innovation is built on a foundation of proven, reliable technology. To see how this legacy is applied to contemporary industry challenges, you can follow our professional insights on LinkedIn{:target=”_blank”}.