In the realm of high-precision manufacturing, where tolerances are measured in microns and part geometries grow increasingly complex, a specialized class of machine tool stands out for its unique ability to produce long, slender, and intricate components with exceptional accuracy: the Swiss CNC machine. For clients seeking precision parts machining and customization, understanding this technology is crucial for selecting the optimal manufacturing process for their projects.

Unlike conventional CNC lathes, a Swiss-type lathe, or Sliding Headstock lathe, employs a distinctive moving-headstock design. The workpiece is held firmly in a collet within a sliding headstock (the “guide bushing”) and is fed axially past stationary or synchronized cutting tools. This fundamental difference is the key to its unparalleled performance for specific part families.

H2: The Core Mechanics: What Sets a Swiss CNC Machine Apart?

The magic of Swiss CNC machining lies in its ingenious approach to combating deflection—the enemy of precision when machining long, thin parts.

The Guide Bushing: This is the heart of the system. The material bar stock passes through a hardened, precision guide bushing that supports the workpiece mere millimeters away from the cutting tool. This proximity provides immense support, virtually eliminating tool pressure-induced deflection.

Sliding Headstock: Instead of the tool moving longitudinally along the part, the headstock slides the part past the tools. This allows for extreme stability during machining.

Multi-Axis Tooling: Modern Swiss-type lathes are equipped with numerous tool stations, often including driven (live) tooling for milling, drilling, and cross-working operations, enabling complete machining in a single setup.

H2: Swiss CNC vs. Conventional CNC Turning: A Strategic Comparison

Choosing between Swiss and conventional turning depends entirely on the part’s characteristics.

| Feature | Swiss CNC Machine | Conventional CNC Lathe |

|---|---|---|

| Part Shape | Ideal for long, slender parts (L:D ratio > 3:1) with complex features. | Best for shorter, stubbier parts, chucked components, and larger diameters. |

| Support & Precision | Unmatched support via guide bushing enables ultra-high precision and fine surface finishes on delicate parts. | Support relies on the tailstock or steady rest; more prone to deflection on long, thin parts. |

| Setup & Efficiency | Excellently efficient for high-volume production of complex, small parts. Complete machining in one chucking. | May require multiple setups (turning, then secondary ops) to complete a complex part, increasing time and potential error. |

| Material Waste | Typically lower. The bar stock is fed incrementally, and parts are cut off as they are finished. | Can be higher, especially for chucked parts where remnant material remains in the chuck. |

| Complexity | Superior at machining parts with complex, off-center, or radial features using live tooling and secondary spindles. | More limited in complex, single-setup machining unless equipped with a milling turret (mill-turn centers). |

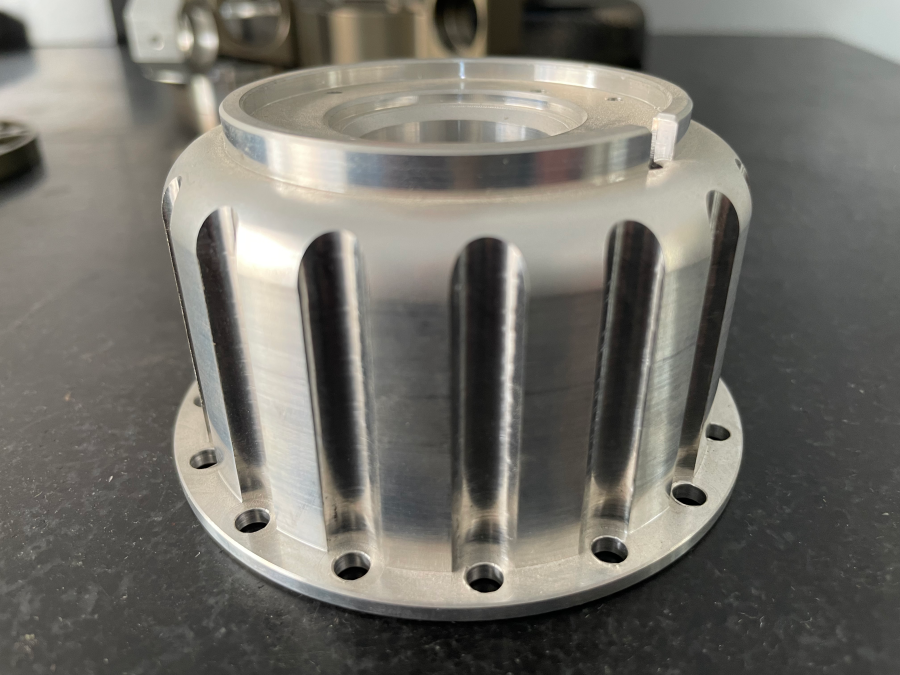

H2: Key Applications and Industries Served by Swiss CNC Machining

The unique advantages of Swiss CNC make it indispensable across several high-tech industries:

Medical & Surgical Devices: Bone screws, spinal implants, surgical instrument shafts, dental components, and biopsy needles. The need for biocompatible materials (like titanium, stainless steels) and flawless surface integrity is perfectly met.

Aerospace & Defense: Precision shafts, pins, connectors, and fasteners used in fuel systems, avionics, and guidance systems, where reliability is non-negotiable.

Electronics & Connectors: Complex pins, contacts, and miniature connectors that require intricate machining and excellent conductivity.

Automotive: Fuel injection components, sensor housings, and transmission pins that demand high-volume precision.

Watchmaking & Micro-Mechanics: The original application, still vital for crafting exquisite, tiny watch components.

H2: Integrating Swiss CNC into a Holistic Manufacturing Strategy

For clients, the decision rarely ends at choosing a single process. The most successful projects leverage a synergistic manufacturing ecosystem. This is where partnering with a full-service manufacturer like GreatLight CNC Machining Factory proves invaluable. While we specialize in advanced precision 5-axis CNC machining services for complex 3D geometries, our comprehensive understanding of the entire precision machining landscape allows us to provide unbiased, strategic guidance.

A part might feature a complex, sculpted body best produced via 5-axis machining, integrated with a precision slender shaft that is ideal for Swiss turning. A partner with a broad technology portfolio can objectively analyze your design, recommend the most efficient and cost-effective process mix—be it Swiss CNC, 5-axis machining, milling, or 3D printing—and execute all stages under one roof. This integrated approach, governed by stringent quality systems like ISO 9001:2015 and IATF 16949, ensures seamless workflow, consistent quality, and reduced lead times.

Conclusion

So, what is a Swiss CNC machine? It is a precision engineering marvel, specifically engineered to conquer the challenges of machining long, slender, and complex miniature parts with super-lative accuracy and efficiency. Its guide bushing and sliding headstock design solve fundamental physics problems inherent in conventional machining. For projects involving such components—common in medical, aerospace, and electronics fields—it is often the superior and sometimes the only viable manufacturing solution. The ultimate key to success lies in collaborating with a manufacturing partner who not only possesses advanced capabilities like Swiss CNC but also the broad expertise and holistic viewpoint to integrate it into your product’s optimal manufacturing pathway.

Frequently Asked Questions (FAQ)

Q1: What are the typical size limitations for parts made on a Swiss CNC machine?

A: Swiss machines excel with smaller diameter parts, typically ranging from 0.5mm (0.02″) up to around 32mm (1.25″) in bar stock diameter, with lengths that can exceed 300mm (12″) or more, depending on the machine. They are masters of the “small but long” domain.

Q2: Is Swiss CNC machining only for metal parts?

A: No. While most commonly used for metals like stainless steel, aluminum, titanium, and brass, Swiss machines can also process engineering plastics like PEEK, Ultem, and Delrin with equal precision, which is critical for many medical and insulator components.

Q3: Why is Swiss CNC often associated with higher costs?

A: The perception of higher cost comes from machine complexity and setup. However, for suitable parts, the total cost is frequently lower. The ability to produce a finished part from bar stock in one continuous operation eliminates secondary setups, reduces handling, minimizes scrap, and dramatically increases throughput, offering significant savings in high-volume production.

Q4: My part has both turned features and complex milled contours. Can a Swiss CNC handle this?

A: Absolutely. Modern Swiss-type lathes are equipped with live (driven) tooling and often a secondary spindle. This allows for operations like cross-drilling, slot milling, polygon milling, and back-working all in the same cycle, making them highly capable “done-in-one” machines for complex components.

Q5: How do I decide if my part is better suited for Swiss CNC or a conventional lathe?

A: The primary rule of thumb is the length-to-diameter ratio. If your part is long and slender (L:D > 3:1), Swiss CNC is likely the best choice for maintaining precision. For shorter parts or those requiring large diameter facing, a conventional lathe may be more efficient. Consulting with an application engineer at a experienced supplier like GreatLight CNC Machining Factory is the best way to get a definitive, data-driven recommendation. For more insights into precision manufacturing partnerships, you can follow industry developments on platforms like LinkedIn.