In the relentless pursuit of manufacturing perfection, where component complexity defies conventional machining and time-to-market pressures mount, the evolution of CNC technology presents a paradigm shift. Beyond the ubiquitous 3-axis and advanced 5-axis systems lies a realm of ultra-high flexibility and capability: the world of 7-axis CNC machining. This technology represents not just an incremental improvement, but a fundamental rethinking of how a single machine tool can interact with a workpiece. So, what is a 7 axis CNC machine? At its core, it is a highly sophisticated machining center that integrates seven distinct degrees of freedom, enabling the cutting tool to approach the workpiece from virtually any angle in a single, continuous setup. This capability is revolutionizing the production of complex, monolithic parts in aerospace, medical, automotive, and energy sectors.

Deconstructing the Axes: Beyond the Basic Three

To understand a 7-axis machine, one must first grasp the standard axes.

The Linear Axes (X, Y, Z): These are the three fundamental Cartesian movements. The X-axis is typically left-to-right, Y-axis is front-to-back, and Z-axis is up-and-down. A standard 3-axis CNC machine operates within this framework.

The Rotational Axes (A, B, C): These introduce tilt and rotation. The A-axis rotates around the X-axis, B around the Y-axis, and C around the Z-axis. A standard 5-axis CNC machine utilizes any two of these rotational axes in addition to X, Y, and Z, allowing for intricate contouring and undercut machining.

A 7-axis CNC machine builds upon this 5-axis foundation by adding two more degrees of freedom. The specific configuration can vary, but two common setups are:

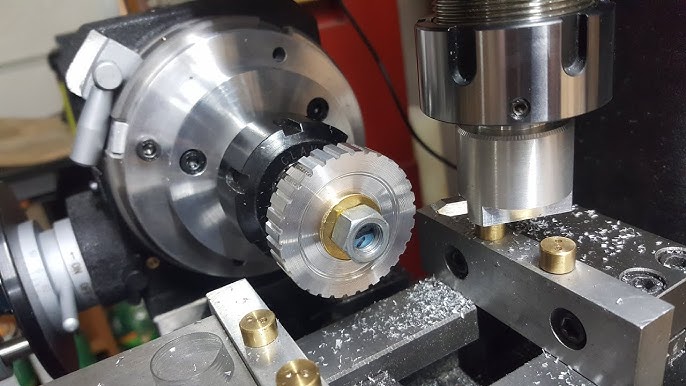

5 Axes + Rotary Table + Additional Spindle Axis: This is a prevalent configuration. You have the standard 5 axes (X, Y, Z, and two rotational, e.g., A and C). The workpiece is mounted on a rotary table that provides an additional rotational axis. Furthermore, the spindle itself may have the ability to move linearly along its own centerline or rotate, providing the seventh axis. This allows for unparalleled access and the ability to machine multiple sides of a part in one clamping.

Twin-Spindle / Multi-Turret with Independent Movement: In some advanced lathe-mill complexes or machining centers, you might have two independent spindles or turrets, each capable of movement in several axes. The coordinated, simultaneous movement of these two tooling systems contributes to the total axis count, enabling operations like simultaneous front and back machining on a turned part.

The Transformative Advantages of 7-Axis Machining

The leap from 5-axis to 7-axis machining unlocks a suite of powerful benefits that directly address critical pain points in modern manufacturing.

Unprecedented Geometric Freedom and Single-Setup Machining: The most significant advantage is the ability to machine extraordinarily complex geometries—such as impellers, turbine blades, orthopedic implants, and intricate automotive prototypes—in a single setup. This eliminates the need for multiple re-fixturing operations, which are time-consuming and introduce cumulative alignment errors.

Dramatic Reduction in Lead Times and Improved Efficiency: By completing a part in one setup, non-cutting time (for setup changes, part repositioning, and re-zeroing) is drastically reduced. Furthermore, the additional axes often allow for the use of shorter, more rigid cutting tools that can operate at optimal speeds and feeds, improving metal removal rates.

Superior Surface Finish and Enhanced Precision: Minimizing part handling and re-clamping directly translates to higher accuracy and better surface finish. Each time a part is moved, there is a potential for error (often measured in microns). 7-axis machining maintains a single, consistent datum throughout the entire process, ensuring exceptional dimensional integrity and eliminating errors from repeated setups.

Optimal Tool Orientation and Extended Tool Life: The machine can continuously orient the cutting tool to maintain the most favorable cutting angle and consistent chip load. This reduces tool wear, minimizes vibrations, and can prevent tool deflection, leading to longer tool life, more consistent part quality, and the ability to achieve finer details.

Machining of Previously “Unmachinable” Features: Certain features, like deep internal cavities with small openings or complex undercuts on all sides of a part, become feasible. The machine can maneuver the tool into positions that are physically impossible for machines with fewer axes.

Ideal Applications: Where 7-Axis Technology Shines

This technology is not for every part. Its value is maximized in high-complexity, high-value, or low-volume/high-mix production scenarios:

Aerospace & Defense: Monolithic airframe components, engine structural parts, complex ducting, and landing gear components with integral stiffeners.

Medical & Dental: Patient-specific orthopedic implants (hips, knees, spinal cages), surgical instruments, and dental abutments with complex organic geometries.

Automotive & Motorsport: Lightweight structural components, complex engine blocks or cylinder heads, and high-performance prototype parts where design iteration speed is critical.

Energy Sector: Turbine blades (both for power generation and aviation), complex pump housings, and components for oil & gas exploration.

Advanced Tool & Mold Making: Complex injection molds with intricate cooling channels and multi-slide actions.

Challenges and Considerations

Adopting 7-axis machining comes with significant considerations:

High Capital Investment: These are among the most expensive machine tools on the market, requiring a substantial upfront investment.

Advanced Programming & Engineering Expertise: Programming a 7-axis machine is exponentially more complex than 3 or 5-axis work. It requires sophisticated CAM software and highly skilled programmers and engineers to generate efficient, collision-free toolpaths that leverage the full potential of the machine.

Maintenance and Calibration: The mechanical complexity is higher, demanding rigorous preventive maintenance and frequent calibration to ensure all seven axes remain in perfect synchronization and alignment.

Not a Universal Solution: For simpler parts, the cost and complexity cannot be justified. The return on investment is realized only when machining parts that truly require this level of capability.

Partnering with a Capable Manufacturer: The Critical Role of Expertise

Owning a 7-axis machine is one thing; mastering it is another. For most businesses, partnering with a specialized manufacturer that has invested in both the technology and the human expertise is the most pragmatic path. A partner like GreatLight CNC Machining Factory exemplifies this approach. While operating a comprehensive fleet that includes advanced 5-axis centers, their deep technical foundation in multi-axis machining principles, rigorous process engineering, and commitment to certifications like ISO 9001:2015 and IATF 16949 create the essential ecosystem needed to handle projects approaching 7-axis complexity. They focus on solving the core client pain points—the “precision black hole,” setup-induced errors, and extended lead times—through intelligent process design, often achieving 7-axis-like outcomes through optimized 5-axis strategies and secondary operations, delivering reliability without unnecessary cost escalation.

For projects that genuinely demand the absolute pinnacle of simultaneous machining, they leverage their network and engineering insight to guide clients to the most suitable specialized resources, ensuring the manufacturing solution matches the technical requirement precisely.

Conclusion

So, what is a 7 axis CNC machine? It is the vanguard of subtractive manufacturing, a system that merges extreme mechanical flexibility with digital intelligence to conquer manufacturing challenges that were once deemed impossible or prohibitively expensive. It represents the ultimate solution for producing highly complex, integrated components in a single, fluent machining operation. While its application is specialized, its impact on enabling innovation in high-tech industries is profound. For engineers and designers pushing the boundaries of what is possible, understanding this technology is key to unlocking new product potential. The journey from a 3D model to a flawless physical part for the most demanding applications increasingly travels through the advanced kinematic pathways of multi-axis machining, with 7-axis standing as a testament to engineering ambition and precision.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between a 5-axis and a 7-axis CNC machine?

A: The core difference is the number of simultaneous degrees of freedom. A 5-axis machine can move the cutting tool along three linear axes (X, Y, Z) and rotate it along two rotational axes (e.g., A and B). A 7-axis machine adds two more independent movements, which could be an additional rotary table for the workpiece, movement of the spindle itself, or coordinated movement of a second independent tool turret. This allows for even more complex tool positioning and single-setup machining of parts with features on all sides.

Q2: Is 7-axis machining always better than 5-axis machining?

A: Not always. “Better” is defined by the specific part requirements. 7-axis machining is superior for parts of extreme, all-around complexity that benefit from a single setup. However, it is far more expensive in terms of machine cost, programming time, and maintenance. For the vast majority of complex parts, 5-axis machining is more than sufficient and represents a more cost-effective and efficient solution. The key is to choose the right technology for the job.

Q3: What industries benefit the most from 7-axis CNC machining?

A: Industries that design and manufacture high-value, low-volume, and geometrically complex components see the greatest benefit. This includes aerospace (for engine and airframe parts), medical (for custom implants), high-end motorsports, energy (turbine components), and advanced defense contracting.

Q4: How does programming for a 7-axis machine differ from programming for a 3 or 5-axis machine?

A: The complexity increases dramatically. Programming requires advanced CAM software capable of simulating all seven axes of movement simultaneously to prevent collisions between the tool, holder, spindle, and workpiece. The programmer must have a deep understanding of machine kinematics, toolpath optimization for continuous multi-axis movement, and strategies to maintain tool rigidity. It is a highly specialized skill set.

Q5: Can a manufacturer with strong 5-axis capabilities handle parts that might seem to need 7-axis?

A: Often, yes. An experienced and technically adept manufacturer like GreatLight CNC Machining Factory can frequently deconstruct a highly complex part into a sequence of intelligent 5-axis operations and precision fixturing setups. Their deep engineering support allows them to achieve the required geometry, precision, and surface finish without the premium cost of dedicated 7-axis machining, providing an optimal balance of performance and value for many challenging projects. They assess the true necessity of 7-axis on a case-by-case basis, ensuring clients pay only for the capability they truly need. For ongoing insights into advanced manufacturing, follow industry leaders on platforms like LinkedIn.