What Does A CNC Machine Cost?

In the world of precision manufacturing, CNC machines are indispensable tools. But what exactly does a CNC machine cost? This is a question that many potential buyers have. Understanding the factors that influence the cost can help you make a more informed decision.

Factors Influencing CNC Machine Costs

Machine Type

CNC machines come in various types, including mills, lathes, routers, and grinders. Each type has its own price range based on its complexity and functionality. For example, a basic 3-axis CNC mill might be less expensive than a multi-axis machine capable of complex geometries.

Precision and Accuracy

Higher precision and accuracy requirements typically increase the cost. Machines that can achieve tolerances within ±0.001mm are more expensive due to their advanced technology and stricter quality control processes.

Brand and Manufacturer

Reputable brands and well-known manufacturers often charge a premium for their machines. This is because they invest heavily in research and development, ensuring their machines are reliable and efficient.

Features and Customizations

Additional features such as automatic tool changers, pallet changers, and advanced software capabilities can significantly increase the cost. Customizations made to meet specific production needs can also add to the expense.

Production Volume

Machines designed for high-volume production are typically more expensive than those for small-scale operations. This is because they are built to withstand heavy use and require less maintenance.

Average Costs

While prices can vary widely, here are some general estimates:

Entry-Level CNC Mills: $10,000 – $50,000

Mid-Range CNC Mills: $50,000 – $200,000

High-End CNC Mills: $200,000 – $1,000,000+

CNC Lathes: $5,000 – $300,000

Multi-Axis Machines: Prices can exceed $1,000,000 depending on complexity

Why Choose GreatLight CNC Machining Factory?

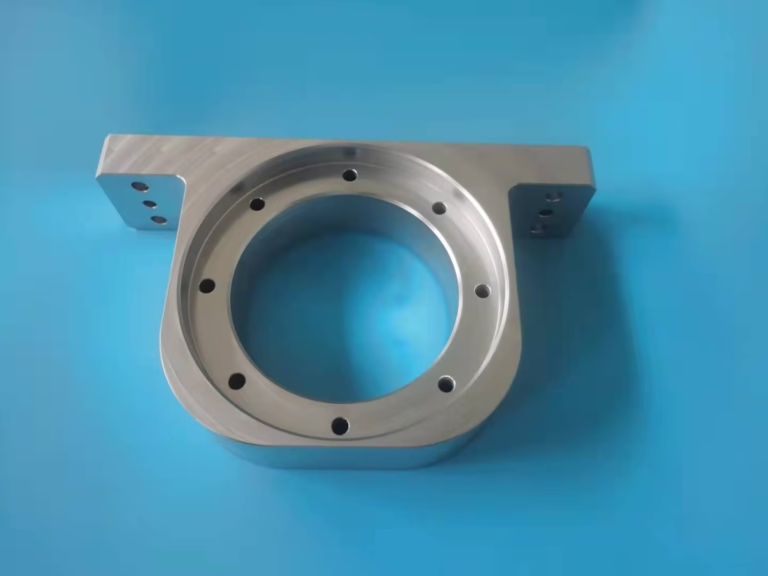

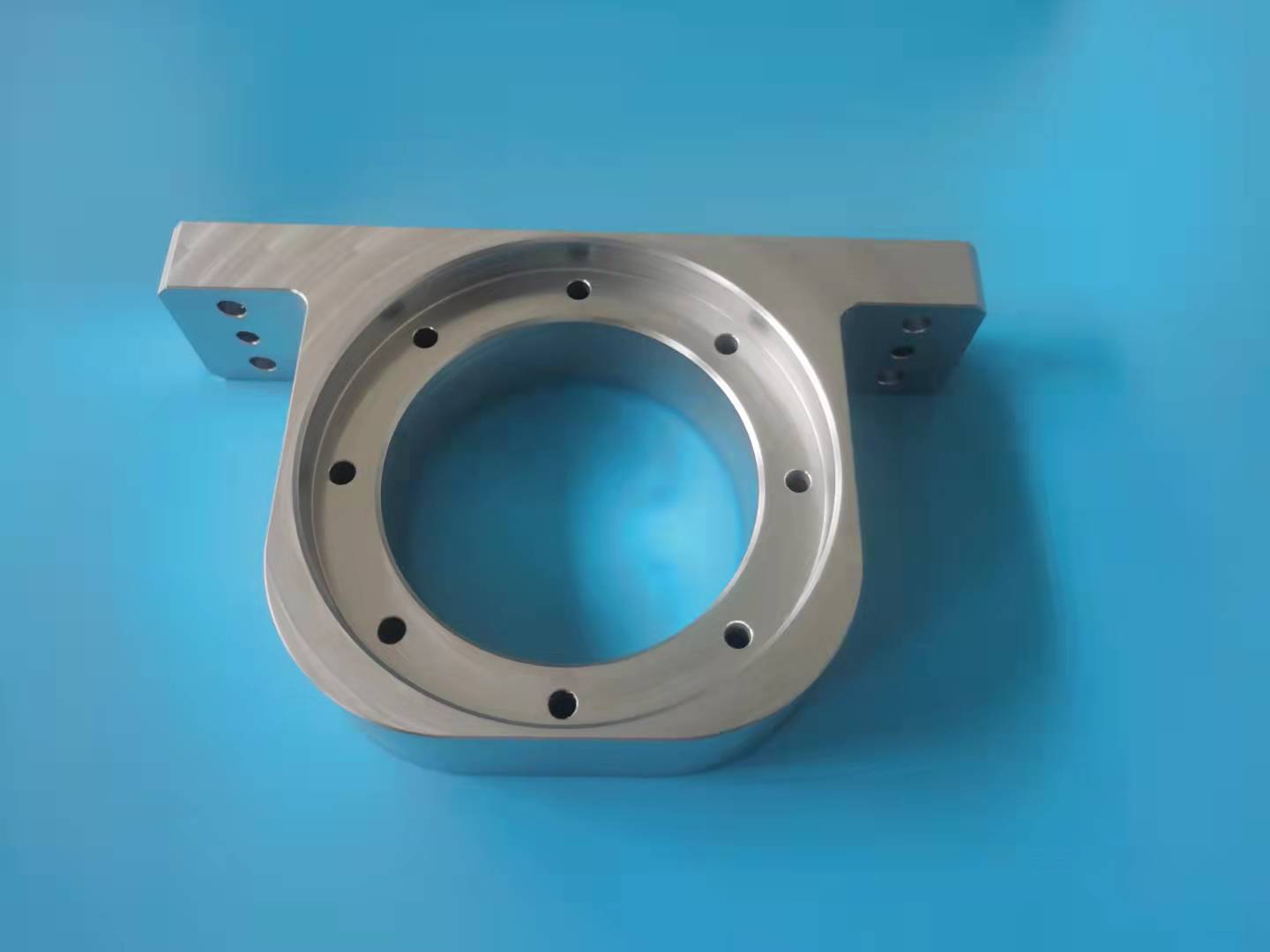

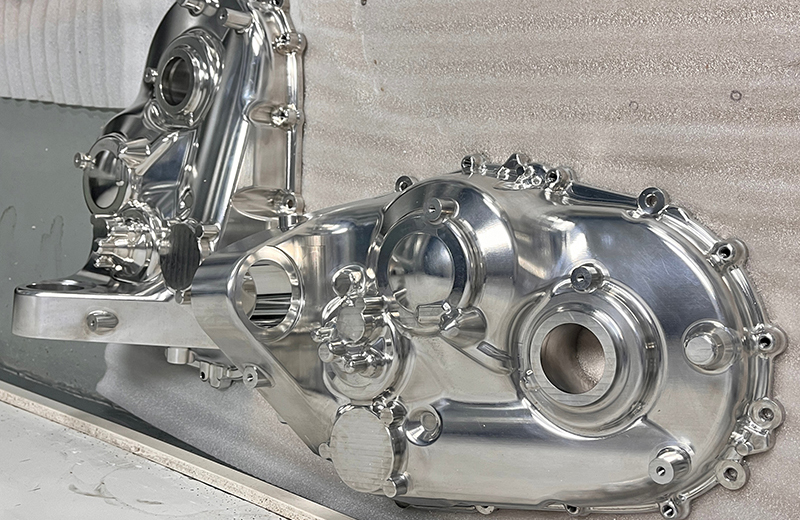

When considering the cost of CNC machines, it’s also important to think about the overall value you’re getting. GreatLight CNC Machining Factory offers not just machines, but a comprehensive suite of services including design, processing, customized production, and application of precision prototype models. Our advanced five-axis CNC machining capabilities ensure high precision and efficiency, making us a cost-effective solution in the long run.

Our factory is equipped with state-of-the-art machinery, including large high-precision five-axis, four-axis, and three-axis CNC machining centers, lathes, milling machines, grinding machines, EDM machines, and 3D printers. This extensive equipment allows us to handle complex projects and deliver high-quality parts with tight tolerances.

Moreover, GreatLight CNC Machining Factory is ISO 9001:2015 certified, ensuring our processes meet international quality standards. We also offer free rework for quality problems and a full refund if rework is still unsatisfactory, providing you with peace of mind.

Conclusion

The cost of a CNC machine depends on various factors, including type, precision, brand, features, and production volume. While the initial investment can be significant, choosing a reliable partner like GreatLight CNC Machining Factory can provide long-term value through high-quality machining services and comprehensive support.

For more information on how GreatLight CNC Machining Factory can meet your precision machining needs, visit our precision 5-axis CNC machining services.

FAQ

Q: Are there financing options available for purchasing CNC machines?

A: Yes, many manufacturers and dealers offer financing options or leasing plans to help spread the cost over time.

Q: How do I determine which type of CNC machine is right for my needs?

A: Consider the specific requirements of your projects, including the complexity of the parts, the materials you’ll be working with, and the production volume.

Q: Can I get a quote for a custom CNC machine?

A: Absolutely. Contact GreatLight CNC Machining Factory with your specifications, and we can provide a tailored quote.

Q: What kind of training and support do you offer for CNC machines?

A: We provide comprehensive training and ongoing support to ensure you get the most out of your machine.

Q: How do I maintain my CNC machine to ensure longevity?

A: Regular maintenance, proper lubrication, and adherence to operating guidelines are key. GreatLight CNC Machining Factory also offers maintenance services and support.

By choosing GreatLight CNC Machining Factory, you’re not just investing in a machine; you’re partnering with a team dedicated to your success in precision manufacturing.