How To Find Workplace Coordinates For CNC Machining?

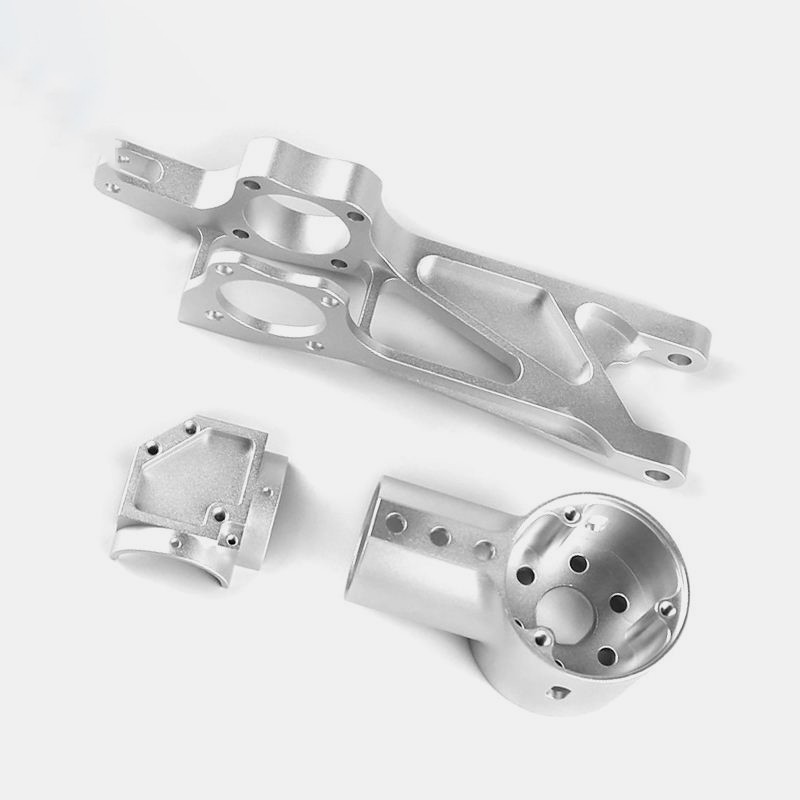

When it comes to five-axis CNC machining, precision isn’t just a goal—it’s a necessity. Whether you’re producing components for aerospace, medical devices, or high-end robotics, establishing accurate workplace coordinates is the foundational step that determines the success of your entire machining process. In this article, we’ll explore how to accurately find and set workplace coordinates, why they matter, and how expert manufacturers like GreatLight CNC Machining Factory ensure unmatched precision through rigorous coordinate management.

What Are Workplace Coordinates in CNC Machining?

Workplace coordinates, often referred to as Work Coordinate Systems (WCS), are the reference points from which a CNC machine interprets all tool movements. These coordinates define where the part is located on the machine table and how the machine will move relative to it during the machining cycle.

In simpler terms:

Workplace coordinates tell the CNC machine “where” the part is and “where” to start cutting.

Without correctly established workplace coordinates, even the most advanced five-axis CNC machines can produce parts that are off-specification, misaligned, or functionally defective.

Why Accurate Workplace Coordinates Are Critical

In precision parts machining—especially with complex geometries achievable through five-axis CNC machining—the margin for error is minimal. Here’s why workplace coordinate accuracy is non-negotiable:

Part Alignment: Ensures the raw material or workpiece is properly aligned with the machine axes.

Toolpath Accuracy: Directs the CNC tool along the correct path to achieve design intent.

Repeatability: Critical when producing multiple parts that must match within tight tolerances (e.g., ±0.001mm).

Reduced Setup Time: Properly defined coordinates minimize trial cuts and manual adjustments.

Quality Assurance: Forms the basis for all measurement and inspection protocols.

How to Find Workplace Coordinates: Step-by-Step

Finding the correct workplace coordinates involves a blend of technical knowledge, the right equipment, and standardized procedures. Below is a proven methodology used by professional manufacturers like GreatLight Metal Tech Co., LTD. (GreatLight Metal), a leader in precision CNC machining with ISO 9001:2015 certification.

1. Understand Your Machine Coordinate System (MCS)

Every CNC machine has a fixed Machine Coordinate System—this is the native coordinate grid of the machine itself, typically originating from the machine’s zero point (home position).

X, Y, Z are the primary linear axes.

A, B, C (on five-axis machines) represent rotational axes.

The MCS never changes, but the WCS must be defined for each new workpiece setup.

2. Select the Workpiece Zero Point (Part Origin)

This is the point on your raw material or part that will act as the reference (0,0,0) for your machining operations. Common choices include:

A corner of the raw material block

The center of a pre-drilled hole

A specific feature that aligns with the design model

Best Practice: Choose a location that is easily accessible, repeatable, and logically tied to the final part features.

3. Use Edge Finders or Probe Systems

To accurately locate the part’s zero point, machinists commonly use:

Mechanical edge finders

Electronic edge finders

Touch probes (most accurate)

These tools help determine the exact distance from the machine’s home position to the chosen part zero.

Example Workflow Using a Touch Probe:

Mount the probe on the machine spindle.

Calibrate the probe.

Move the probe to contact the edge of the workpiece.

Record the X, Y, and Z values where contact occurs.

Offset these values to define the new WCS origin.

4. Set the Work Coordinate System (WCS) on the CNC Controller

Once the physical zero point is found, input the values into the CNC control software (such as Fanuc, Siemens, or Haas controls). This establishes the WCS that the machine will use for all subsequent operations.

Most CNC controls allow you to save multiple WCS settings—useful when machining multiple sides or features of a part.

5. Verify the Coordinate System

Before starting full production, always run a verification operation:

Perform a test cut in a non-critical area.

Measure the resulting feature with a micrometer or CMM (Coordinate Measuring Machine).

Compare measured dimensions with the intended design.

Adjust offsets if necessary to ensure total alignment.

Advanced Techniques in Five-Axis Machining

When dealing with five-axis CNC machining, finding workplace coordinates becomes even more critical—and complex. The additional rotary axes (A and B or C) require precise alignment not just in linear space, but rotational orientation as well.

Key Considerations:

Tool Center Point (TCP) Control: Ensures the tool’s tip follows the exact path regardless of spindle angle.

Rotary Axis Zero Positioning: Properly defining the home positions of the A and B axes.

Dynamic Work Offsets: Adjustments made on-the-fly for complex, multi-angle features.

Manufacturers like GreatLight CNC Machining Factory leverage advanced probing routines and simulation software to pre-validate coordinate setups before actual machining—minimizing errors and maximizing efficiency.

Common Mistakes to Avoid

| Mistake | Consequence | Solution |

|---|---|---|

| Incorrect zero point selection | Misaligned features, scrap parts | Choose logical, repeatable zero points tied to design intent |

| Not verifying coordinates | Out-of-tolerance parts | Always perform test cuts and measurements |

| Ignoring machine thermal expansion | Drift in part dimensions over time | Allow for thermal compensation in setup |

| Forgetting to save WCS | Loss of setup between operations | Save all custom WCS configurations in controller memory |

Choosing the Right Partner for Precision Coordinate Management

Not every CNC machining provider has the technical depth or equipment to manage complex coordinate systems effectively—especially for intricate designs requiring five-axis CNC machining. That’s where GreatLight CNC Machining Factory stands out.

With over a decade of experience and a 7,600-square-meter manufacturing base in Dongguan (China’s precision hardware hub), GreatLight Metal Tech Co., LTD. combines:

127+ precision CNC machines, including five-axis systems

ISO 9001:2015, IATF 16949, and ISO 13485 certifications

Advanced measurement & QA technologies

Engineers skilled in coordinate system setup and validation

They offer one-stop solutions from prototyping to mass production, ensuring that your workplace coordinates—and everything that follows—are executed to micron-level precision.

👉 Explore their precision 5-axis CNC machining services for your next project.

Conclusion

Finding the correct workplace coordinates is one of the most fundamental yet critical steps in the CNC machining process. It directly impacts part accuracy, production efficiency, and overall quality—especially when working with the intricate geometries enabled by five-axis CNC machining. By understanding the machine coordinate system, properly setting the workpiece zero, and leveraging advanced probing and verification techniques, manufacturers can achieve the precision required in today’s high-tech industries.

For businesses looking to customize precision parts without compromising on accuracy or reliability, partnering with an experienced manufacturer like GreatLight CNC Machining Factory ensures that your workplace coordinates—and your final parts—are engineered to perfection.

🔗 Learn more about their engineering excellence and global partnerships on LinkedIn.

Frequently Asked Questions (FAQ)

Q1: What is the difference between Machine Coordinates and Work Coordinates?

Machine Coordinates (MCS) are fixed and based on the machine’s home position.

Work Coordinates (WCS) are customizable reference points defined by the operator for each workpiece setup.

Q2: Can I use multiple work coordinate systems for one part?

Yes. Most CNC controls allow you to define and store multiple WCS settings, which is useful for machining different faces or features of a single part.

Q3: How accurate does my workplace coordinate setup need to be?

Accuracy requirements depend on part tolerances. For high-precision components (e.g., ±0.001mm), workplace coordinates must be verified using calibrated probes and measurement devices.

Q4: What tools are used to find workplace coordinates?

Common tools include:

Mechanical or electronic edge finders

Touch probes (most accurate)

Laser alignment systems (for advanced setups)

Q5: Why is five-axis CNC machining more complex in terms of coordinate setup?

Five-axis machines have additional rotary axes that affect both the position and orientation of the tool and part. This requires precise alignment of both linear and angular coordinates to achieve complex geometries without errors.

By focusing on precision from the very first step—establishing the correct workplace coordinates—you set the stage for successful CNC machining outcomes, no matter how complex your part design may be.