How To Build A CNC Machine With Aluminum Extrusion?

When it comes to custom precision parts machining, especially in industries demanding high repeatability, tight tolerances, and fast turnaround, five-axis CNC machining has become the gold standard. However, not every business or innovator is ready—or needs—to invest in commercial-grade machinery right away. For prototyping, small-batch production, educational purposes, or R&D, building your own CNC machine using aluminum extrusion offers a compelling balance between cost-efficiency, flexibility, and performance. In this guide, we’ll explore how to construct a functional CNC machine using aluminum extrusion, why it’s a strategic choice, and how it compares to professional solutions like those offered by GreatLight CNC Machining Factory—your expert partner for high-precision parts and integrated manufacturing solutions.

Why Consider Building a CNC Machine with Aluminum Extrusion?

Aluminum extrusion is the backbone of countless DIY and semi-professional CNC builds due to its unique combination of properties:

Lightweight yet strong: Ideal for reducing inertia while maintaining structural integrity.

Modular and configurable: Easily cut, drilled, and assembled into various frame geometries.

Cost-effective: More affordable than steel or custom machined components.

Corrosion-resistant and machinable: Simplifies maintenance and modifications.

Thermally stable: Minimizes expansion-related inaccuracies under temperature fluctuations.

For businesses or individuals aiming to customize precision parts, experimenting with a self-built CNC machine using aluminum extrusion can serve as a valuable stepping stone before scaling up to industrial-grade solutions like five-axis CNC machining.

What You’ll Need to Build a CNC Machine with Aluminum Extrusion

1. Core Structural Components

Aluminum Extrusion Profiles: Common profiles include 2020 (light-duty), 2040, and 4040 (heavy-duty). Choose based on the expected load and size of your machine.

Joining Elements: T-slot nuts, bolts, brackets, and angle connectors for modular assembly.

Linear Rails & Bearings: Provide smooth, accurate motion along X, Y, and Z axes.

Lead Screws or Ball Screws: Convert rotary motion from motors into linear movement. Ball screws offer higher precision.

NEMA Stepper Motors or Servo Motors: Drive the axes. Servos offer better feedback and control.

Motor Drivers & Controllers: Such as GRBL, Arduino CNC Shield, or more advanced systems like LinuxCNC or Mach3.

Power Supply: Match voltage and current requirements of your motors and drivers.

CNC Controller Software: Typically runs on a PC or Raspberry Pi; interfaces with G-code.

2. Frame Design

A rigid and square frame is critical for accuracy. Common configurations include:

Cartesian (X-Y-Z): The most common and straightforward design.

CoreXY: Offers faster movements with less torque needed on belts.

H-Bot: Simpler than CoreXY but can be less stable.

Using aluminum extrusion, you can assemble a fully adjustable, square, and rigid frame that accommodates your desired build volume.

Step-by-Step: How to Build a Basic 3-Axis CNC Machine

Step 1: Design Your Frame

Determine the working area (X, Y, Z dimensions) based on your project needs.

Sketch a 3D model or use CAD software to plan the layout.

Select aluminum extrusion sizes (e.g., 2040 or 4040 for the main frame, 2020 for supports).

Step 2: Assemble the Frame

Cut the extrusions to length using a miter saw or hacksaw.

Use T-slot nuts and bolts to assemble the frame. Ensure all corners are square using a square tool or digital angle finder.

Add cross-bracing if needed to enhance rigidity.

Step 3: Install Linear Motion Systems

Mount linear rails on the X and Y axes. Secure them firmly to prevent deflection.

Attach carriages with bearings that glide along the rails.

For the Z-axis, consider using a ball screw for better precision, especially if working with small, detailed parts.

Step 4: Mount the Stepper Motors

Affix stepper motors to drive the lead screws or belt systems on each axis.

Ensure proper alignment to avoid binding or uneven motion.

Step 5: Connect Electronics

Wire stepper motors to motor drivers (e.g., TB6600, A4988, or DRV8825).

Connect drivers to a controller board (e.g., Arduino Uno with CNC Shield, or GRBL-compatible boards).

Hook up the power supply and ensure all connections are secure and correctly polarized.

Step 6: Install the Cutting Tool

For milling machines, mount a router (e.g., Dremel or trim router) or end mill spindle.

Ensure the tool is vertically aligned and securely fastened to prevent vibrations.

Step 7: Software Setup

Install CNC control software on your computer (e.g., Pronterface, bCNC, or Candle).

Configure the software to communicate with your controller board.

Import or generate G-code for your parts using CAD/CAM software like Fusion 360, SolidWorks CAM, or FreeCAD.

Step 8: Calibration and Testing

Perform axis calibration to ensure accurate movement.

Test with scrap material before machining valuable components.

Fine-tune motor speeds, feed rates, and acceleration settings for optimal performance.

Advantages of a DIY Aluminum Extrusion CNC Machine

| Benefit | Description |

|---|---|

| Cost Savings | Significantly lower upfront investment compared to commercial CNC machines. |

| Customizability | Tailor the size, configuration, and features to your exact needs. |

| Educational Value | Great for learning the fundamentals of CNC mechanics, electronics, and software. |

| Rapid Prototyping | Enables quick iteration of designs before committing to professional manufacturing. |

| Scalability | Start small and upgrade components (motors, screws, controllers) as needed. |

When to Transition to Professional CNC Machining

While building your own CNC machine is a rewarding endeavor, it has limitations in terms of precision, repeatability, and material capabilities. For high-precision parts machining, especially in industries like aerospace, medical, automotive, and robotics, professional solutions are non-negotiable.

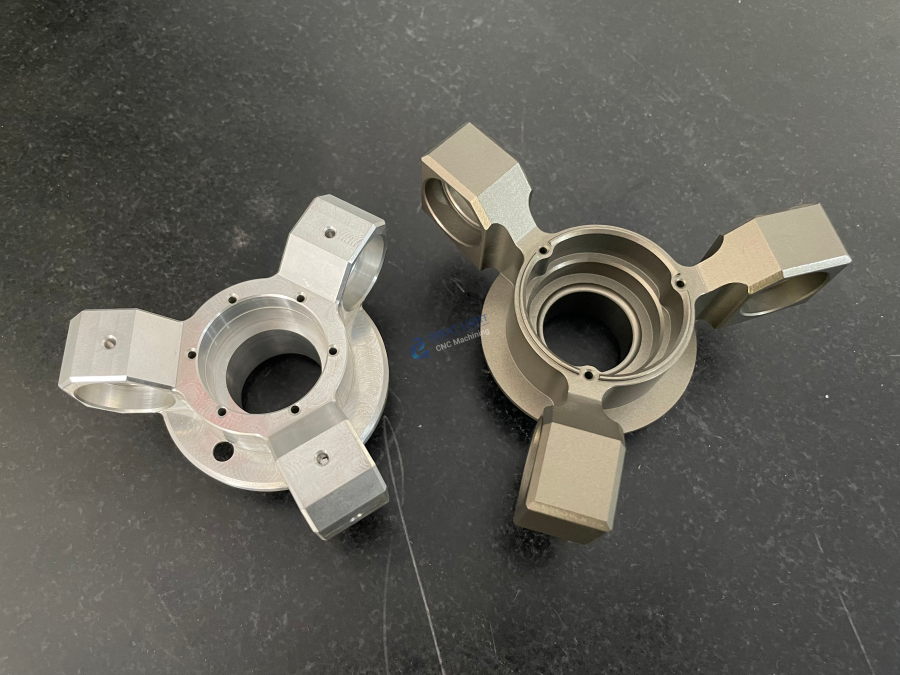

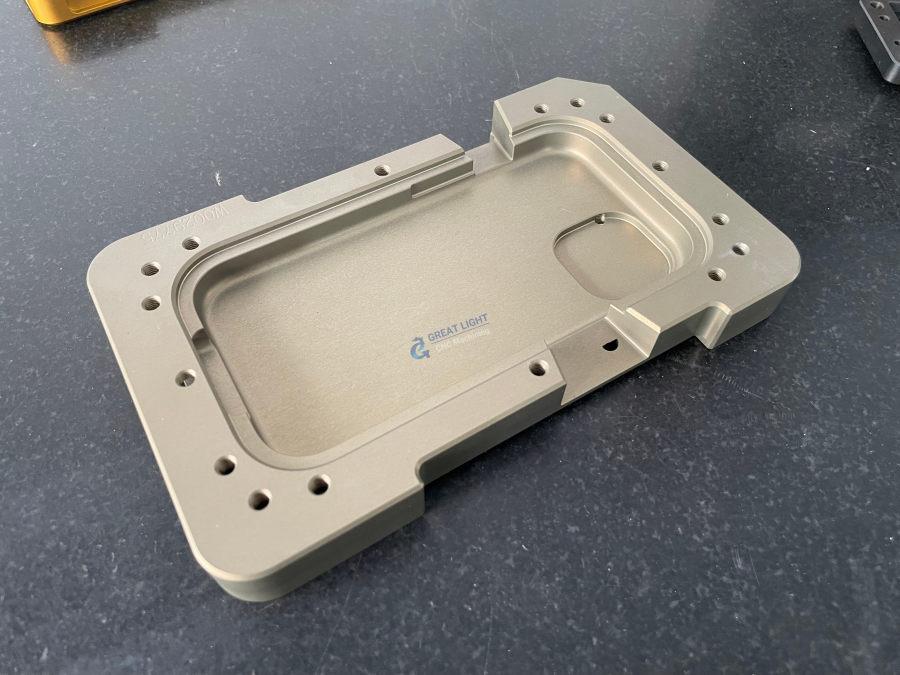

This is where GreatLight CNC Machining Factory shines. With over a decade of experience and a fleet of advanced five-axis CNC machining centers, the factory specializes in solving complex manufacturing challenges with ±0.001mm precision. Their capabilities include:

Five-axis CNC machining

CNC milling and turning

Die casting and mold making

3D metal and plastic printing (SLM/SLA/SLS)

Sheet metal fabrication

Comprehensive post-processing and surface finishing

Moreover, GreatLight Metal is ISO 9001:2015 certified, ensuring that every part meets stringent quality standards. Whether you’re producing prototype models or end-use components, their one-stop manufacturing services eliminate the hassle of sourcing multiple vendors.

🔗 Learn more about their precision 5-axis CNC machining services here: GreatLight CNC Machining Services (new window).

Conclusion

Building a CNC machine with aluminum extrusion is an excellent way to dive into the world of precision machining, offering flexibility, hands-on learning, and cost advantages. It’s particularly well-suited for prototyping, hobbyists, small workshops, and educational institutions. However, for mission-critical applications that demand uncompromising precision, advanced materials, and certified quality, partnering with a trusted manufacturer like GreatLight CNC Machining Factory ensures that your parts are produced to the highest standards.

By starting with a DIY approach and eventually scaling up to professional five-axis CNC machining, you can achieve the best of both worlds—innovation and precision.

Frequently Asked Questions (FAQ)

Q1: Is aluminum extrusion strong enough for a CNC machine frame?

Yes, especially when using profiles like 2040 or 4040. These provide an excellent balance of strength, weight, and modularity for most DIY and even some light industrial applications.

Q2: What’s the difference between 3-axis, 4-axis, and 5-axis CNC machining?

3-axis: Moves in X, Y, and Z directions. Suitable for basic milling.

4-axis: Adds rotation around the X-axis (A-axis), enabling more complex shapes.

5-axis: Adds two rotational axes, allowing simultaneous movement for intricate geometries and reduced setup time.

Q3: Can I achieve industrial-grade precision with a DIY CNC machine?

While you can achieve good precision for hobbyist and prototyping purposes (typically ±0.1mm to ±0.05mm), professional machines like those from GreatLight CNC Machining Factory offer ±0.001mm precision, which is essential for critical applications.

Q4: What materials can I machine with a DIY CNC machine?

Common materials include wood, plastics (like acrylic and PVC), aluminum (soft grades), and PCBs. Machining harder metals or advanced composites usually requires industrial-grade equipment.

Q5: Why choose GreatLight CNC Machining Factory over other manufacturers?

GreatLight Metal combines decades of expertise, ISO-certified quality systems, full-process manufacturing capabilities, and state-of-the-art 5-axis CNC machining. They serve high-end industries including aerospace, automotive, medical, and robotics. Learn more about their trusted global partnerships here: GreatLight Metal on LinkedIn (new window).

Whether you’re assembling your own CNC system or sourcing precision components, understanding the capabilities and limitations of each approach ensures smarter decision-making for your manufacturing needs.