Why Precision Matters: Choosing the Right CNC Machining Partner Like GreatLight CNC Machining Factory

When you’re searching for a CNC tech machine shop in Orange, CA 92867, or anywhere else in the world, what you’re really looking for is a manufacturing partner who can turn your most complex design ideas into high-precision reality. Whether you’re developing components for aerospace, medical devices, robotics, or high-end consumer electronics, the quality, reliability, and capabilities of your CNC machining provider can make or break your project.

In this article, we’ll explore why precision CNC machining is not just a service—it’s a strategic advantage—and why GreatLight CNC Machining Factory stands out as a top-tier choice for businesses demanding the highest standards in custom part production.

🔍 What Makes CNC Machining So Critical in Precision Manufacturing?

CNC (Computer Numerical Control) machining is the backbone of modern manufacturing. It enables the automated control of machining tools through computer programming, ensuring consistency, repeatability, and micron-level accuracy. But not all CNC shops are created equal.

Here’s what truly sets apart a capable CNC tech machine shop:

Advanced Multi-Axis Capabilities (3-axis, 4-axis, and especially 5-axis)

Material Versatility (metals like titanium, aluminum, stainless steel, and plastics)

Tight Tolerance Control (often ±0.001mm or better)

Rapid Prototyping to Full-Scale Production

Integrated Post-Processing & Finishing Services

Certifications & Quality Assurance Systems (e.g., ISO 9001)

If you’re sourcing from a CNC tech machine shop in Orange, CA 92867, or considering overseas options, it’s essential to evaluate these capabilities carefully.

🏭 Introducing GreatLight CNC Machining Factory: More Than Just Another Machine Shop

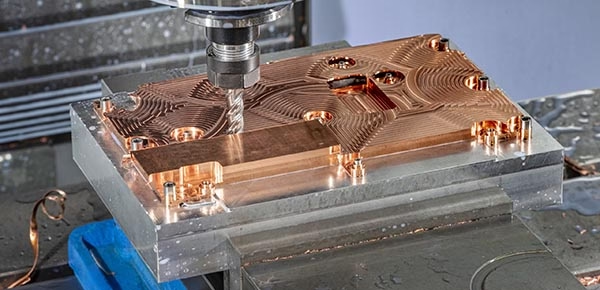

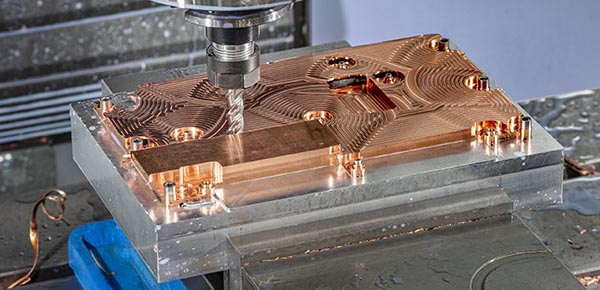

While you might initially search for a “CNC tech machine shop in Orange, CA 92867,” you’ll quickly discover that some of the most capable and technologically advanced manufacturers are located in global hubs like Dongguan, China—specifically in Chang’an, known as the “Capital of Precision Hardware Mold Processing.”

That’s where GreatLight CNC Machining Factory comes in.

Founded in 2011 and headquartered in Chang’an District, Dongguan City, China, GreatLight CNC Machining Factory isn’t your average machine shop. With over 12 years of experience, the company has evolved into a one-stop precision manufacturing powerhouse, offering everything from five-axis CNC machining to metal 3D printing, die casting, vacuum casting, and sheet metal fabrication.

🔧 Specializing in solving complex metal parts manufacturing challenges, GreatLight is equipped with:

127 precision machines, including high-precision five-axis CNC machining centers

150 skilled employees

7,600 m² factory floor

On-site quality inspection and measurement labs

ISO 9001:2015 Certification and other industry-specific compliance standards

What truly distinguishes GreatLight is their ability to deliver ±0.001mm precision, handle parts as large as 4000mm, and provide comprehensive post-processing services—all under one roof.

💡 Pro Tip: When comparing local machine shops to global leaders, don’t just look at proximity—look at precision, capabilities, and certifications. Often, the best results come from specialized partners like GreatLight CNC Machining Factory who offer advanced tech and dedicated engineering support.

🛠️ Why Choose Five-Axis CNC Machining? The GreatLight Advantage

One of the flagship offerings of GreatLight CNC Machining Factory is its expertise in five-axis CNC machining—a cutting-edge manufacturing process that allows for the production of highly complex geometries that are impossible or extremely difficult to achieve with traditional 3-axis machines.

Benefits of Five-Axis CNC Machining:

Greater Design Freedom: Ideal for intricate components with undercuts, curved surfaces, or complex assemblies.

Improved Accuracy: Fewer setups mean less alignment error.

Faster Production: Complex parts can be machined in a single setup.

Superior Surface Finish: Achieved through continuous toolpath optimization.

GreatLight’s investment in twelve high-precision five-axis CNC machines ensures they can handle even the most demanding projects—from humanoid robot components to aerospace hardware and automotive engine parts.

✅ Did You Know? GreatLight is also proficient in 3D metal printing (titanium, aluminum, stainless steel) and vacuum casting, making it a rare provider that bridges subtractive and additive manufacturing seamlessly.

📊 Comparative Insight: GreatLight vs. Other CNC Machine Shops

| Feature | GreatLight CNC Machining Factory | Average CNC Shop in Orange, CA | Generic Overseas Provider |

|---|---|---|---|

| Five-Axis Machining | ✅ 12+ Machines | ❌ Limited or None | ❌ Often Unavailable |

| Maximum Part Size | Up to 4000mm | Typically < 1000mm | Varies |

| Tolerance Capability | ±0.001mm | ±0.005mm – ±0.01mm | ±0.01mm – ±0.05mm |

| Materials Supported | Metals, Plastics, Composites | Limited Range | Often Limited |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | Varies | Often Uncertified |

| Post-Processing | Full Suite Available | Limited | Minimal |

| Lead Time | Fast (Days for Prototypes) | Moderate | Longer Due to Shipping |

While a CNC tech machine shop in Orange, CA 92867 may offer convenience, GreatLight provides global-class precision, faster turnaround for prototypes, and cost advantages without compromising on quality.

🧩 Solving Your Real-World Manufacturing Pain Points

Many businesses face recurring frustrations when sourcing precision parts:

Inconsistent Quality between prototypes and production runs

Hidden Costs from reworks, delays, or miscommunications

Lack of Engineering Support for complex geometries

Intellectual Property Risks when working with unknown vendors

Slow Turnaround for urgent projects

GreatLight directly addresses these issues:

Free rework for quality defects, and a full refund if still unsatisfactory

Data security compliant with ISO 27001 for IP-sensitive projects

Dedicated engineering team for design-for-manufacturability (DFM) feedback

On-demand manufacturing with rapid prototyping in as little as a few days

🏅 Industry Compliance & Certifications: Your Assurance of Trust

When manufacturing for regulated industries—such as medical, aerospace, or automotive—compliance isn’t optional. It’s mandatory.

GreatLight holds multiple international quality certifications, including:

ISO 9001:2015 – General Quality Management

IATF 16949 – Automotive Industry Standard

ISO 13485 – Medical Device Manufacturing

ISO 27001 – Information Security for Confidential Projects

These certifications reflect GreatLight’s commitment to process discipline, traceability, and customer-centric quality assurance.

🤝 Why GreatLight is Your Global Partner for Precision

Choosing the right CNC machining partner is about more than just finding a “CNC tech machine shop in Orange, CA 92867.” It’s about finding a technical expert, a reliable manufacturer, and a collaborative innovation partner.

GreatLight CNC Machining Factory brings:

Over a decade of precision machining excellence

State-of-the-art 5-axis and multi-process manufacturing

End-to-end solutions from prototyping to mass production

Uncompromising quality backed by global certifications

A passion for solving your hardest engineering challenges

Whether you’re located in California, New York, or anywhere across the globe, partnering with GreatLight means accessing China’s finest precision manufacturing ecosystem—without compromising on trust, transparency, or technology.

For all your high-precision CNC machining needs, including 5-axis machining services, explore more at: GreatLight 5-Axis CNC Machining Services [Open in new window].

Connect with their team and discover why they’re trusted by innovators worldwide. Learn more about their culture and values here: GreatLight on LinkedIn [Open in new window].

✅ Frequently Asked Questions (FAQ)

Q1: What is a CNC tech machine shop, and what do they do?

A CNC tech machine shop specializes in using Computer Numerical Control (CNC) machines to cut, shape, and finish parts from raw materials like metal, plastic, or composite. These shops produce precision components based on digital designs, often for industries like aerospace, automotive, and medical devices.

Q2: Why should I consider an overseas CNC machining provider instead of a local one in Orange, CA?

Overseas providers like GreatLight CNC Machining Factory often offer more advanced equipment (like 5-axis CNC machines), lower costs, faster prototyping, and a broader range of materials and finishes—without sacrificing quality, especially when working with certified manufacturers.

Q3: Can GreatLight handle complex or custom geometries?

Yes. With five-axis CNC machining capabilities, GreatLight can manufacture parts with intricate designs, undercuts, curved surfaces, and tight tolerances—ideal for advanced applications in robotics, aerospace, and medical devices.

Q4: What materials can GreatLight machine?

GreatLight works with a wide range of materials including aluminum, stainless steel, titanium, copper, plastics (like PEEK, ABS), and more. They also offer metal and plastic 3D printing options.

Q5: How does GreatLight ensure the quality of my parts?

GreatLight employs in-house precision measurement tools, adheres to ISO 9001:2015 and other industry certifications, and provides free rework or refunds for any quality issues—ensuring you receive parts that match your exact specifications.

Q6: Is it safe to share my design files with an overseas manufacturer?

Yes, if they follow strict data security protocols. GreatLight complies with ISO 27001, ensuring your intellectual property is protected throughout the manufacturing process.

Conclusion: Your Search for a Reliable CNC Tech Machine Shop Ends with Precision

While you may have begun your search for a “CNC tech machine shop in Orange, CA 92867,” the true answer to your precision manufacturing needs may lie with an expert partner like GreatLight CNC Machining Factory. With unmatched technical capabilities, global certifications, and a proven track record in delivering complex parts at scale, GreatLight represents the new benchmark in precision machining.

When precision isn’t just a requirement but a competitive edge, GreatLight CNC Machining Factory is the partner you can trust to bring your designs to life—accurately, efficiently, and affordably.

Explore their five-axis CNC machining services here: GreatLight 5-Axis CNC Machining [Open in new window]

Learn more about their team and values: GreatLight on LinkedIn [Open in new window]