How To Get Started In CNC Machining?

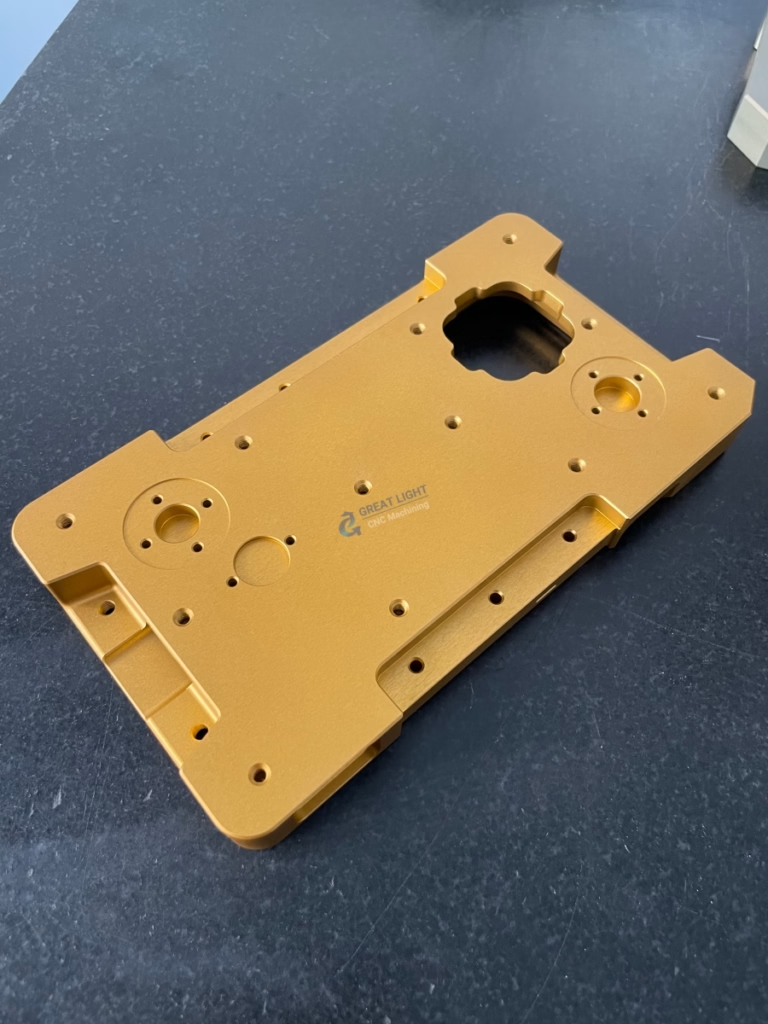

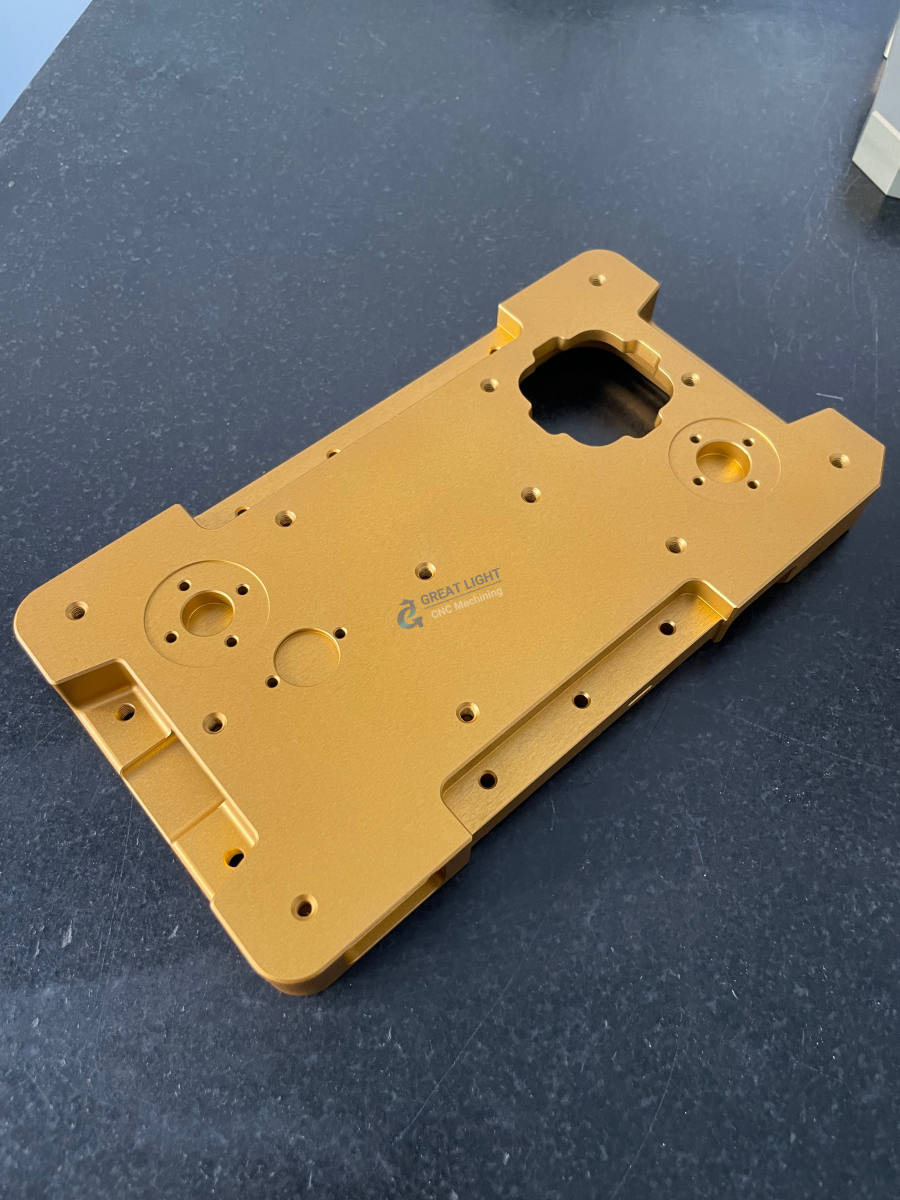

CNC machining is a cornerstone of modern manufacturing, offering precision and efficiency in creating a wide range of parts. If you’re looking to get started in CNC machining, it’s essential to understand the process, the equipment involved, and how to choose the right partner for your projects. GreatLight CNC Machining Factory, also known as Great Light Metal Tech Co., LTD., is a leading player in this field, providing high – precision custom part machining and integrated, one – stop manufacturing services.

Understanding CNC Machining Basics

CNC (Computer Numerical Control) machining is a manufacturing process in which pre – programmed computer software dictates the movement of factory tools and machinery. This technology enables the production of complex parts with high precision. The process starts with a digital design, usually in a CAD (Computer – Aided Design) format. The CAD file is then converted into a CAM (Computer – Aided Manufacturing) program that controls the CNC machine.

Key Steps to Get Started

Education and Training

Formal Education: Consider enrolling in a technical school, community college, or vocational training program that offers courses in CNC machining. These programs typically cover topics such as CAD/CAM software, machine operation, and programming.

On – the – Job Training: Many manufacturers offer apprenticeship or on – the – job training programs. This hands – on experience is invaluable as it allows you to learn directly from experienced machinists.

Learning CAD/CAM Software

CAD Software: Programs like AutoCAD, SolidWorks, and Fusion 360 are widely used in the industry. These tools allow you to create detailed 3D models of the parts you want to machine.

CAM Software: Mastering CAM software such as Mastercam, GibbsCAM, or Fusion 360’s CAM capabilities is crucial. CAM software takes the CAD model and generates the toolpaths necessary for the CNC machine to cut the part.

Familiarizing with CNC Machines

Types of Machines: There are different types of CNC machines, including CNC mills, lathes, routers, and grinders. Each machine has its own capabilities and applications. For example, a CNC mill is suitable for creating complex shapes, while a CNC lathe is ideal for turning cylindrical parts.

Machine Operation: Learn how to operate the CNC machine safely. This includes understanding the control panel, loading and unloading tools, and setting up the workpiece.

Why Choose GreatLight CNC Machining Factory?

GreatLight CNC Machining Factory has several advantages that make it an ideal choice for those starting in CNC machining or looking for a reliable partner for their projects:

Advanced Equipment: The factory is equipped with 127 pieces of precision peripheral equipment, including large high – precision five – axis, four – axis, and three – axis CNC machining centers. These advanced machines can handle complex geometries and ultra – high precision requirements. Click here to learn more about their precision 5 – axis CNC machining services.

Comprehensive Services: They offer a full – process chain encompassing precision CNC machining, die casting, sheet metal fabrication, 3D printing, and mould manufacturing. This one – stop service saves time and effort for clients.

Quality Assurance: GreatLight CNC Machining Factory is an ISO 9001:2015 certified manufacturer. They strictly adhere to ISO quality standards, and their in – house precision measurement and testing equipment ensure that all materials and parts meet the specifications.

Experience and Expertise: With over a decade of experience in precision prototype model processing, the factory has the technical know – how to solve complex manufacturing challenges. They can handle projects from concept to mass production.

Conclusion

Getting started in CNC machining requires a combination of education, training, and hands – on experience. By understanding the basics of CNC machining, learning the necessary software, and familiarizing yourself with the equipment, you can embark on a successful journey in this field. GreatLight CNC Machining Factory is a reliable partner that can provide the support and services you need to bring your projects to life. Whether you’re a beginner or an experienced professional, their advanced technology, comprehensive services, and commitment to quality make them a top choice for CNC machining. Remember, when you’re looking to get started in CNC machining, GreatLight CNC Machining Factory can be your key to success.

Frequently Asked Questions (FAQ)

What materials can GreatLight CNC Machining Factory work with?

GreatLight CNC Machining Factory can work with most materials. They have experience in processing metals such as aluminum, steel, titanium, and plastics.

How long does it take to get a quote for a CNC machining project?

The time to get a quote depends on the complexity of the project. However, GreatLight CNC Machining Factory strives to provide quick and accurate quotes. Usually, you can expect a response within a few business days.

Can GreatLight CNC Machining Factory handle small – scale projects?

Yes, they can handle projects of various scales, from small – scale prototypes to large – scale mass production.

What if there are quality issues with the machined parts?

GreatLight CNC Machining Factory offers after – sales guarantee. They will provide free rework for quality problems, and if rework is still unsatisfactory, they will offer a full refund.

Does the factory have experience in specific industries?

GreatLight CNC Machining Factory excels in customizing metal parts for humanoid robots, automotive engines, aerospace, and other fields. You can visit their LinkedIn page to learn more about their service cases.