For engineers, designers, and procurement specialists navigating the complex world of automotive manufacturing, the journey of a part doesn’t end when the CNC machine finishes its final pass. In fact, one of the most critical phases that determines a part’s performance, longevity, and aesthetic integration begins right after machining: surface finishing.

The selection of an appropriate finishing process for CNC machined car parts is not a mere afterthought; it is a fundamental engineering decision. It bridges the gap between a precision-machined substrate and a component that must survive harsh environments, meet stringent safety standards, and satisfy discerning visual criteria. From the blistering heat of an engine bay to the corrosive assault of road salts, and from the high-wear dynamics of transmission systems to the flawless shine of interior trim, each part demands a finishing strategy tailored to its mission.

This article delves deep into the universe of finishing techniques for automotive CNC components, providing a systematic guide to selecting the right process for the right part.

Why Finishing is Non-Negotiable in Automotive CNC Machining

Before exploring the “how,” it’s essential to understand the “why.” A raw CNC-machined part, while dimensionally accurate, is often unprepared for its end-use environment. Finishing addresses several crucial imperatives:

Corrosion & Chemical Resistance: Automotive parts are exposed to water, salt, UV radiation, fuels, oils, and cleaning agents. Finishing creates a protective barrier that prevents oxidation (rust) and chemical degradation.

Wear Resistance & Durability: Moving parts, bearing surfaces, and gears are subject to constant friction. Certain finishes dramatically increase surface hardness and reduce wear, extending component life.

Aesthetic & Brand Identity: Both exterior and interior parts contribute to the vehicle’s perception. Finishes define color, texture (glossy, matte, brushed), and perceived quality, aligning with brand values.

Functional Performance: Some finishes reduce friction (for improved efficiency), alter electrical conductivity, facilitate solderability, or provide thermal properties.

Preparation for Further Assembly: Finishes can provide an ideal surface for adhesion (painting, bonding) or improve the performance of subsequent coatings.

A Taxonomy of Finishing Processes for Automotive Parts

We can categorize finishing methods based on their primary function and mechanism. The following table provides a high-level overview:

| Category | Primary Function | Common Processes | Typical Substrates |

|---|---|---|---|

| Conversion Coatings | Create a protective layer via chemical reaction. Excellent paint base. | Anodizing (Type II, III), Chromate Conversion, Phosphating | Aluminum, Zinc, Steel |

| Electroplated Coatings | Deposit a metal layer via electrolysis for corrosion resistance, wear, or appearance. | Zinc Plating, Nickel Plating, Chrome Plating, Electroless Nickel | Steel, Copper Alloys |

| Physical Vapor Deposition (PVD) | Deposits a thin, extremely hard, decorative metallic coating in a vacuum. | PVD Chrome, PVD Titanium Nitride (TiN), PVD Zirconium Nitride (ZrN) | Steel, Stainless Steel, Brass |

| Organic Coatings | Apply a liquid or powder polymeric layer for protection and color. | Powder Coating, E-Coating (Cathodic Electrocoat), Wet Painting | All metals (with prep) |

| Mechanical Finishes | Alter surface texture, remove burrs, induce compressive stress. | Vibratory/Bowl Tumbling, Abrasive Blasting, Shot Peening, Brushing/Polishing | All metals |

| Thermal & Diffusion Processes | Infuse elements into the surface at high temperature to enhance properties. | Nitriding, Carburizing | Steel, Titanium |

Detailed Breakdown: Matching Processes to Automotive Applications

Let’s examine these processes in the context of real-world automotive components.

H2: Conversion Coatings: The Foundation of Protection

These processes chemically transform the surface layer of the metal into a stable, integrated oxide or compound layer.

Anodizing (for Aluminum Parts): This is the gold standard for aluminum in automotive applications.

Type II (Sulfuric Acid) Anodizing: Provides good corrosion resistance and is an excellent base for dyeing. Used for under-hood brackets, sensor housings, and interior trim pieces where color (black, red, blue) is desired.

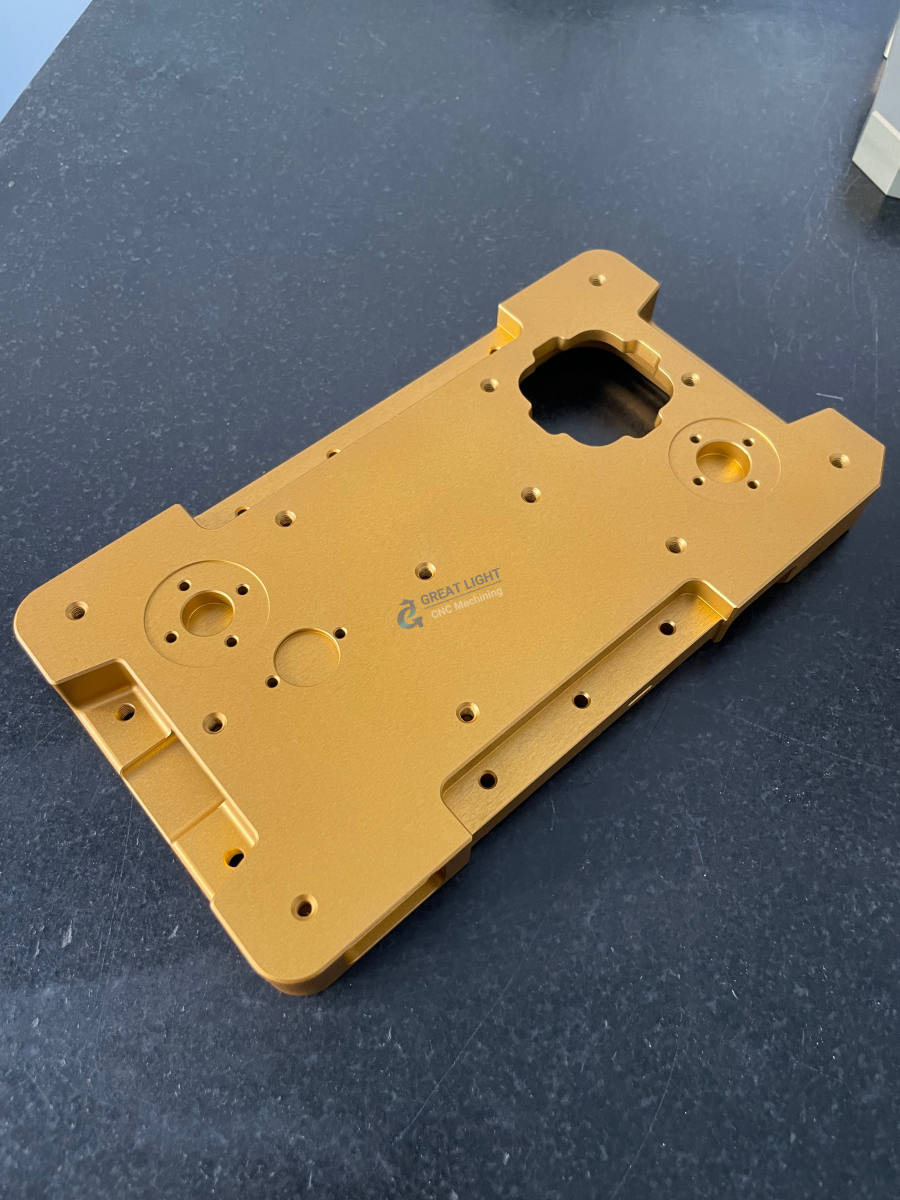

Type III (Hard) Anodizing: Creates a much thicker, denser, and harder oxide layer (up to 60+ Rockwell C). It’s used for high-wear components like transmission valves, pistons, and hydraulic system parts. A partner like GreatLight Metal leverages precise 5-axis CNC machining to create complex aluminum geometries, which are then hard-anodized to achieve unmatched durability in demanding applications.

Chromate Conversion (Iridite, Alodine): Often used on aluminum and zinc alloys. It provides a thin, conductive layer with good corrosion resistance and is a perfect primer for paint or adhesive bonding. Common on electrical connectors, housings, and fasteners.

H2: Electroplated & PVD Coatings: For Wear, Corrosion, and Glamour

Zinc Plating (with Passivation): The most common finish for steel fasteners, brackets, and underbody components. The zinc layer acts as a sacrificial anode. The passivation step (often blue, yellow, or black) adds extra corrosion resistance and color. It’s cost-effective and provides robust protection.

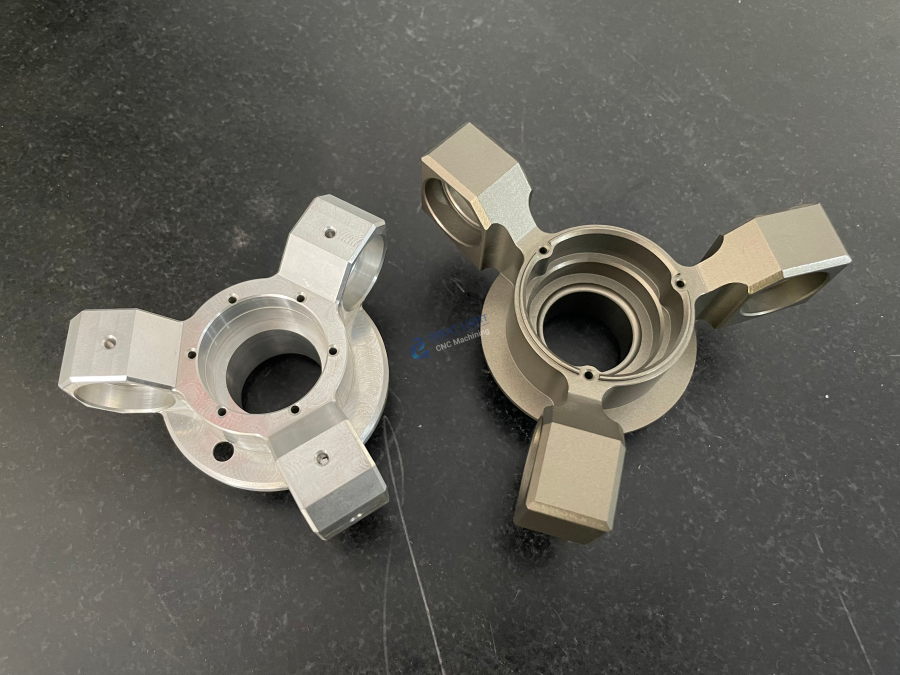

Electroless Nickel Plating (ENP): An autocatalytic chemical process that deposits a uniform nickel-phosphorus alloy coating. Its uniformity is ideal for complex parts with deep recesses or internal passages machined via precision 5-axis CNC. It offers excellent corrosion and wear resistance, and is often specified for fuel system components, brake parts, and hydraulic fittings.

Decorative Chrome Plating: The classic bright, mirror finish for exterior door handles, grilles, and wheel accents. It’s a multi-layer process (copper, nickel, then chrome) over a base metal like steel or brass.

Physical Vapor Deposition (PVD): This is the modern, environmentally friendly successor to decorative chrome for many applications. PVD coatings like PVD Chrome or PVD TiN are extremely thin, hard, and durable. They are highly resistant to tarnishing, corrosion, and wear. You’ll find PVD on high-end interior trim, door sills, and even on cutting tools used in the machining process itself. It allows for a wide range of consistent colors, including gunmetal, bronze, and gold.

H2: Organic Coatings: The Color Workhorses

E-Coating (Electrocoating): A immersion process where the part is electrically charged, attracting paint particles to form an ultra-uniform, corrosion-resistant primer layer over every surface, including edges and complex geometries. Virtually every automotive chassis and body-in-white component undergoes e-coating. It’s the first line of defense against rust.

Powder Coating: A dry powder is electrostatically applied and then cured under heat to form a thick, durable, and attractive finish. It’s available in endless colors and textures (matte, gloss, textured). Used for wheels, suspension components, engine brackets, and aftermarket accessories. It is more environmentally friendly than wet paint and generally more durable.

Wet Painting: Used for detailed color matching and complex multi-layer effects, especially on interior trim and under-hood components that require specific chemical resistance (e.g., to engine oil or coolant).

H2: Mechanical & Thermal Finishes: Engineering the Surface Integrity

Shot Peening: A critical process for safety-critical and fatigue-prone components like valve springs, connecting rods, and gear shafts. It bombards the surface with small media, inducing compressive stresses that dramatically improve fatigue life and resistance to stress-corrosion cracking.

Abrasive Blasting (Bead Blasting, Sand Blasting): Used to clean surfaces, create a uniform matte texture (e.g., on aluminum housings), or prepare a surface for coating. Glass bead blasting gives a smooth, satin finish.

Vibratory Tumbling (Deburring): Essential after CNC machining to remove sharp edges (burrs) and impart a smooth, slightly radiused edge. This is crucial for parts handled during assembly, for safety, and to prevent stress concentrations.

Nitriding/Carburizing: These thermal diffusion processes are for high-strength steel components like gears, crankshafts, and camshafts. They create an extremely hard, wear-resistant surface while maintaining a tough, ductile core—a perfect combination for high-load applications.

H2: Making the Right Choice: A Decision Framework

Selecting a finish involves balancing performance, cost, aesthetics, and environmental regulations. Ask these questions:

What is the Base Material? (Aluminum, steel, stainless steel, magnesium, zinc die-cast?)

What is the Operating Environment? (Under-hood heat, exterior weather, interior UV, chemical exposure?)

What are the Functional Requirements? (Wear resistance, hardness, corrosion resistance, electrical conductivity, friction coefficient?)

What are the Aesthetic Requirements? (Color, gloss level, texture?)

What are the Cost and Volume Constraints?

Are there Regulatory/Safety Standards? (RoHS, REACH, automotive OEM specifications?)

A sophisticated manufacturing partner doesn’t just execute a requested finish; they consult on the optimal choice. For instance, a company like GreatLight Metal, with its integrated one-stop manufacturing solutions, can advise that a CNC-machined aluminum throttle body might best be served by Type III hard anodizing for wear, while a stainless steel decorative emblem might achieve better durability and aesthetics with a PVD coating rather than traditional plating. Their expertise across the entire process chain—from material selection and precision 5-axis CNC machining to post-processing—ensures the finish is not an isolated step but an integrated phase of the manufacturing strategy.

Conclusion

The question “What kind of finishing for CNC machined car parts?” opens the door to a discipline as complex and critical as the machining process itself. From the robust, invisible protection of e-coat on a chassis to the brilliant, durable gleam of PVD on a gear shifter, each finish is a carefully engineered solution to a specific set of challenges.

The evolution of automotive technology—towards electric vehicles with new thermal management needs, lighter materials like advanced aluminum alloys, and更高的 consumer expectations for quality—continues to drive innovation in surface finishing. Success lies in partnering with a manufacturer that possesses not only the technical capability to machine parts to exquisite tolerances but also the deep materials science and process engineering knowledge to finish them for a lifetime of performance. In this integrated approach, the true value of a precision CNC machining service is fully realized, transforming raw material into a component that is ready, reliable, and refined for the road ahead.

Frequently Asked Questions (FAQ)

Q1: What is the most cost-effective corrosion protection for steel brackets and fasteners?

A: Zinc plating with a passivate (e.g., blue or yellow chromate) is typically the most economical and effective choice for general-purpose steel components, offering excellent sacrificial protection.

Q2: We need a black finish for an aluminum heat sink that also improves thermal radiation. What do you recommend?

A: Black Type II (sulfuric) anodizing is ideal. The anodized layer itself has good emissivity, and the black dye further enhances radiative heat dissipation, all while providing good corrosion resistance.

Q3: Our design has deep, narrow channels. Will plating cover these areas evenly?

A: Traditional electroplating often struggles with uniform deposition in deep recesses due to current density variations. Electroless Nickel Plating (ENP) is the superior choice here, as it provides a perfectly uniform coating thickness regardless of part geometry, a significant advantage for parts machined with complex 5-axis CNC toolpaths.

Q4: How does PVD compare to traditional chrome plating for interior trim?

A: PVD is generally more durable, scratch-resistant, and environmentally friendly (it doesn’t use hexavalent chromium). It offers a wider range of consistent, fade-resistant colors. While sometimes higher in initial cost, its longevity and quality often make it the preferred choice for mid-to-high-end applications.

Q5: We are prototyping a new suspension component. How important is finishing at the prototype stage?

A: Critically important. Prototype finishing validates not just aesthetics, but more importantly, the functional performance (wear, corrosion) of your chosen material and process combination. Testing a hard-anodized or nitrided prototype can reveal real-world behavior before committing to costly production tooling. A full-service partner like GreatLight Metal can provide these prototype-level finishing services to de-risk your development cycle.

Q6: What finishing process is best for preventing galling on stainless steel threaded components?

A: For stainless steel fasteners prone to galling (cold welding), a molybdenum disulfide (MoS2) impregnated coating or a thin PVD coating like TiN can drastically reduce friction and prevent this issue during assembly and use.