That’s what people in the industry say when they summarize lighting design, but things are far from that simple. By contacting various solutions, we found that there were still positioning and tightening issues in the preliminary design that are not real. well resolved. The most innovative solutions will lose their practical significance. Only by understanding the basic knowledge of positioning and tightening can we fundamentally guarantee the integrity of the fixture design and processing plan.

Knowledge of the locator

1. Basic principles of positioning from the side of the room

When positioning from the side of the part, just like with the support, the 3-point principle is the most basic principle. This is the same principle as support, called the 3-point principle. It derives from the principle according to which “three points which are not on the same line determine a plane”. Among the 4 points, 3 points can determine an area, so a total of 4 areas can be determined. However, no matter how it is positioned, it is quite difficult to make the 4th point in the same plane.

▲3-point principle

For example, when using four fixed-height positioners, only three points anywhere may contact the part, and it is most likely that the remaining fourth point will not contact the part.

Therefore, when setting up the locator, it is usually based on three points, and the distance between these three points should be increased as much as possible.

In addition, when arranging the positioner, it is necessary to confirm in advance the direction in which the processing load is applied. The direction of the machining load is the direction of movement of the tool holder/tool. Arranging a positioner at the end of the feed direction can directly affect the overall accuracy of the part.

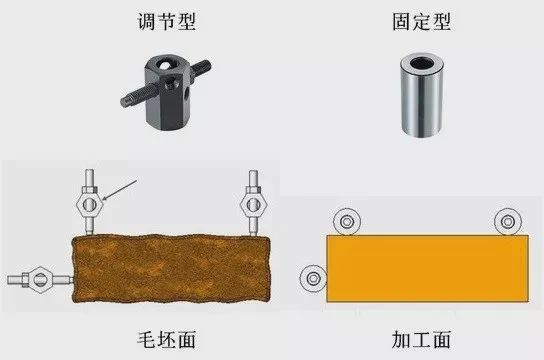

Generally, when positioning the rough surface of the workpiece, a bolt-type adjustable positioner is used, and when positioning the machined surface of the workpiece, a fixed-type positioner (the contact surface of the workpiece is ground) is used.

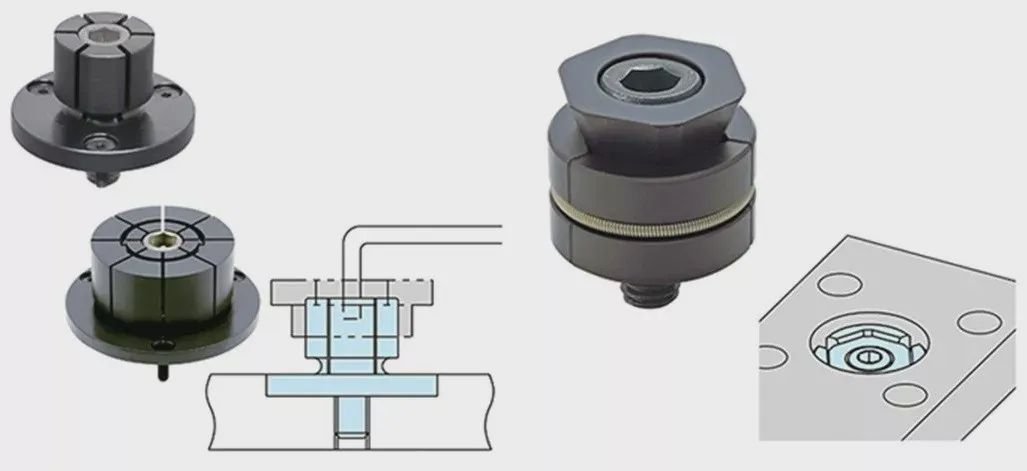

2. Basic principles of positioning from holes in the part

When positioning using the holes processed in the previous process of the part, pins with tolerances must be used for positioning. By matching the workpiece hole accuracy with the pin shape accuracy and combining them according to the fit tolerance, the positioning accuracy can meet the actual requirements.

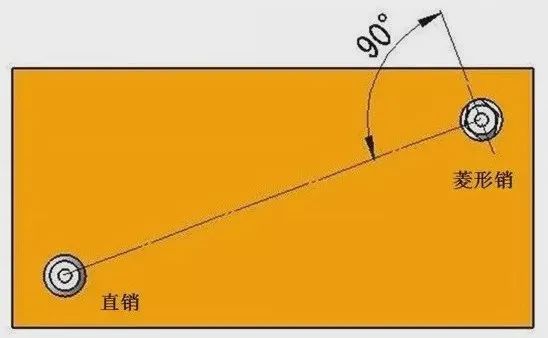

In addition, when using pins for positioning, one usually uses a straight pin and the other uses a diamond pin, so it will be more convenient to assemble and disassemble the part, and the part and the pin will rarely get stuck.

▲Use pin positioning

Of course, it is also possible to use straight pins for both pins by adjusting the fit tolerance. For more precise positioning, it is generally more effective to use a straight pin and a diamond pin.

When using a straight pin and a diamond pin, typically the line connecting the placement direction of the diamond pin (where it contacts the workpiece) is 90° perpendicular to the line connecting the straight pin and the diamond pin. diamond pin. This arrangement is for the good. positioning angle (direction of rotation of the part).

Knowledge related to pliers

1. Classification of pliers

According to the tightening direction, it is generally divided into the following categories:

Next, let’s look at the features of the different pliers.

1. Clamp pressed from above

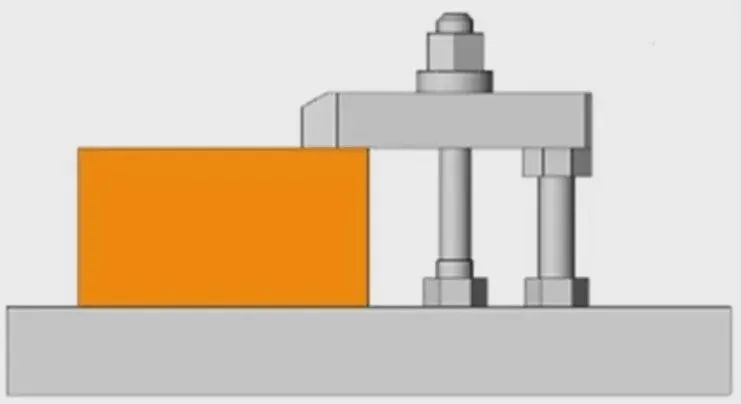

A clamp that clamps the workpiece from above has the least deformation during clamping and is the most stable while processing the workpiece. Therefore, in general, the first consideration is to clamp the workpiece from the top. The most common gripper pressed from above the workpiece is a manual mechanical gripper. For example, the image below is called a “pine leaf type” clamp. The clamp consisting of the pressure plate, studs, cylinders and nuts is called a “loose-leaf” clamp.

In addition, depending on the shape of the workpiece, different shapes of pressure plates can be selected to match different shapes of workpieces.

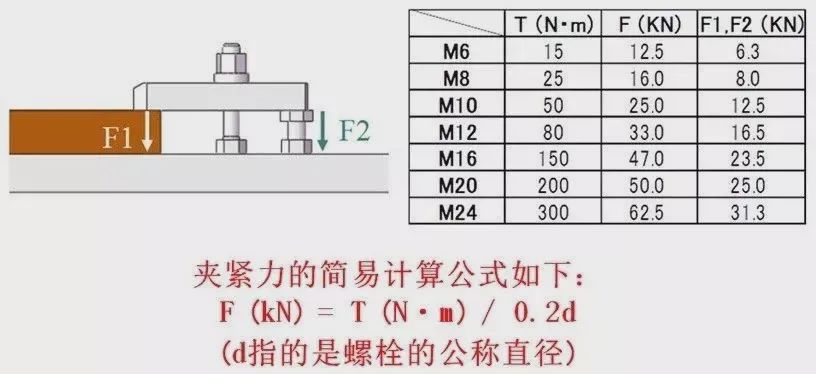

The relationship between torque and clamping force when tightening with loose-leaf pliers can be calculated based on the thrust force of the bolt.

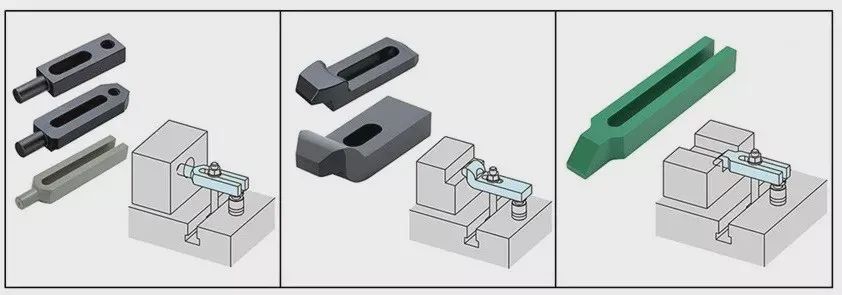

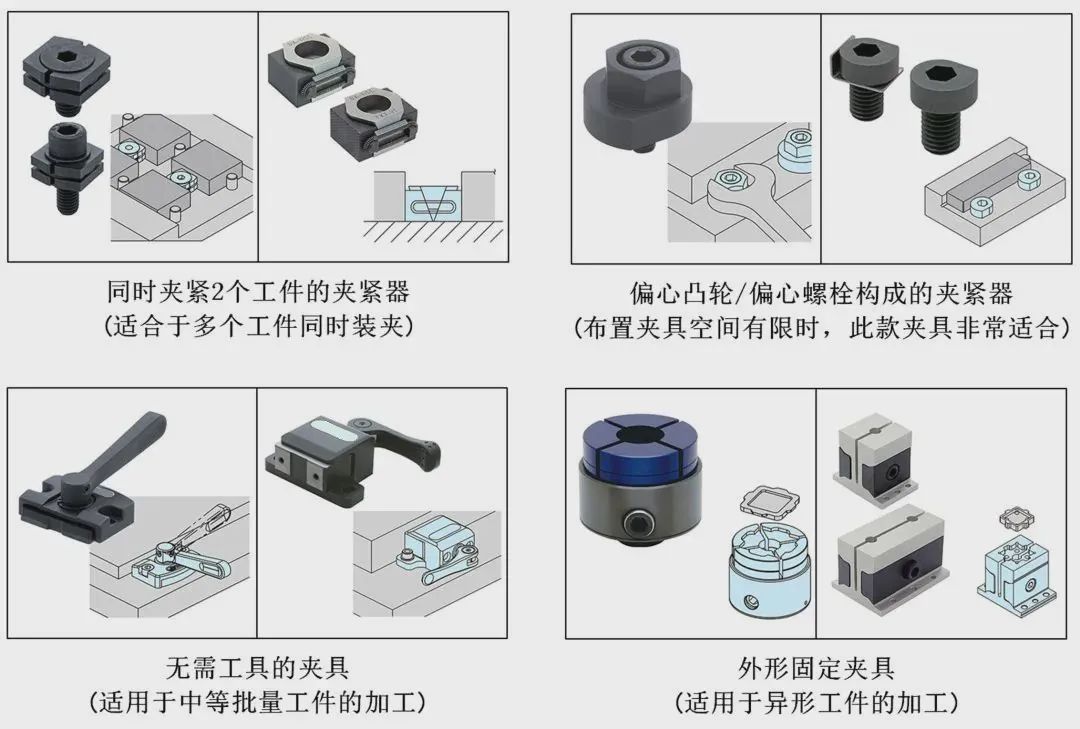

In addition to the loose-leaf clamp, there are also the following similar clamps that clamp the workpiece from above.

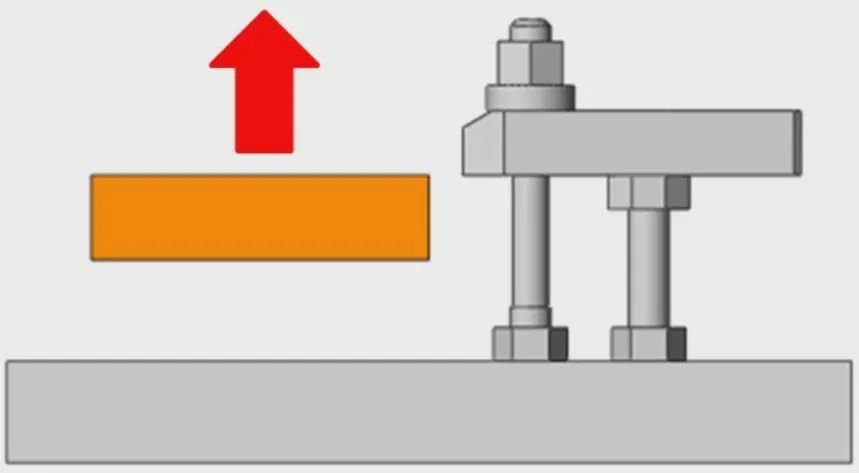

2. Clamp that tightens on the side

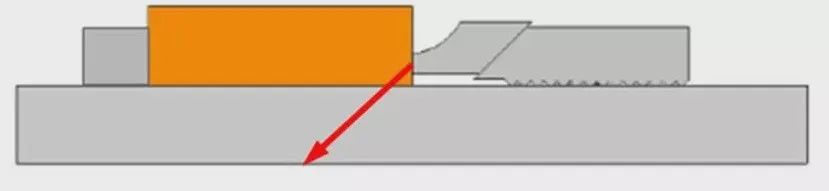

Originally, the clamping method of clamping the workpiece from above has the most stable precision and the smallest processing load on the workpiece. However, when the top of the workpiece needs to be processed, or tightening from the top of the workpiece is not very suitable, etc., and it is impossible to tighten from the top of the workpiece, you can choose to tighten to the side. of the workpiece. However, relatively speaking, when the workpiece is clamped sideways, a floating force will be generated. Attention should be paid to how to eliminate this force when designing the luminaire.

There are also pliers that clamp on the side, as shown in the image above. While generating side thrust, this type of gripper can effectively prevent the workpiece from floating.

Clamps that attach to the side also include the following similar clamps.

3. Clamp that clamps the workpiece from below

When processing the upper surface of a thin sheet metal part, not only cannot it be clamped from the top, but it is also unreasonable to clamp it from the side. The only method of clamping the workpiece from below is a reasonable clamping method. When clamping a workpiece from below, if it is iron, a magnetic type clamp can usually be used. When working with non-ferrous metal parts, vacuum cups can usually be used to clamp them.

In both cases above, the clamping force is proportional to the contact area between the workpiece and the magnet or vacuum chuck. If the processing load when processing small parts is too large, the processing effect will not be ideal.

In addition, when using magnets or vacuum suction cups, the contact surfaces with the magnets and vacuum suction cups should be smooth to a certain extent for safe and normal use.

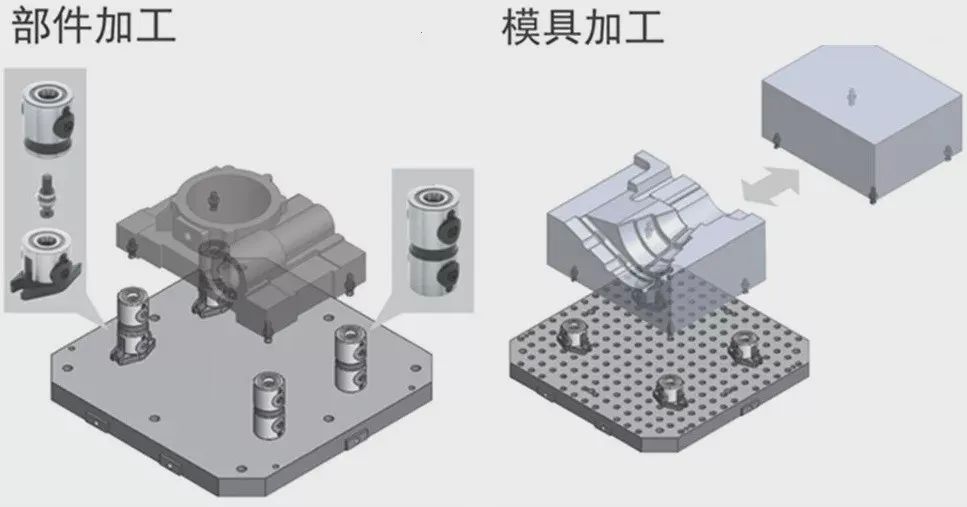

4. Tighten using clamping holes

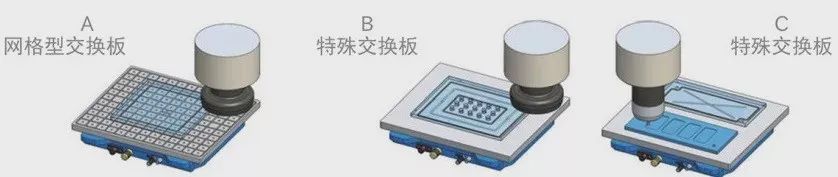

When using a 5-axis processing machine to carry out multi-facet simultaneous processing or mold processing, in order to avoid fixtures and tools affecting the processing, it is generally more appropriate to use clamping through holes. Compared to clamping from the top and side of the part, hole clamping places less load on the part and can actually distort the part.

▲Use holes for direct processing

▲Rivet set for tightening

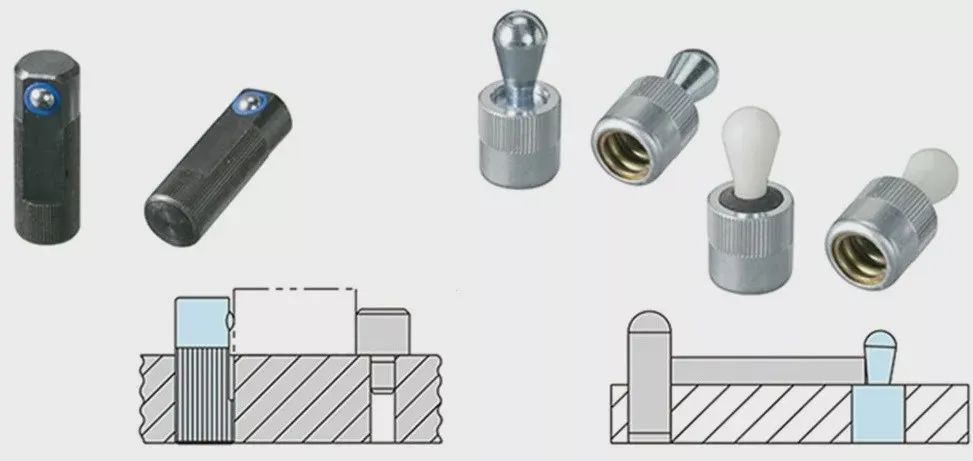

2. Pre-tightening

The above mainly talks about workpiece clamping devices. How to improve operability and improve operability using pre-tightening is also crucial. When the piece is placed vertically on the base, it will fall downward due to gravity. At this point you need to hold the workpiece with your hands while operating the clamp.

▲Pre-tightening

If the workpiece is heavy or several are clamped at the same time, the operability will be greatly reduced and the clamping time will be very long. At present, the use of this spring pre-tightening product can enable the workpiece to operate the clamp while remaining stationary, greatly improving the operability and reducing the workpiece clamping time.

3. Things to Consider When Choosing a Clamp

When using multiple types of clamps in the same tooling, be sure to use the same tools for tightening and loosening. For example, in the left image below, when multiple tool wrenches are used for tightening operations, the overall load on the operator will increase and the overall workpiece tightening time will also become longer. For example, in the right image below, tool wrenches and bolt sizes are unified to facilitate on-site operations.

▲ Operationality of part clamping

In addition, when setting up the clamp, it is necessary to take into account the operability of clamping the workpiece as much as possible. If the workpiece must be tilted during clamping, operability will be very inconvenient. This situation must be avoided when designing the assembly tooling.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.