How GreatLight CNC Machining Factory Elevates Precision Manufacturing Through Advanced Guard Systems

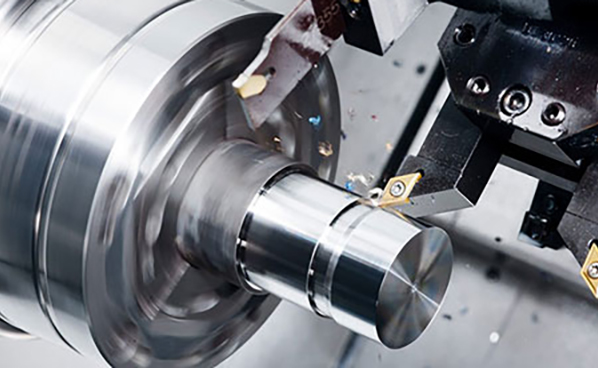

In the dynamic landscape of CNC machining, precision and safety are non-negotiable pillars. As global manufacturers push the boundaries of innovation, the demand for ultra-high-precision parts—especially in automotive, aerospace, and medical sectors—has surged. However, transforming complex 3D designs into flawless physical components hinges on a critical factor: the reliability of CNC machine guard systems.

GreatLight CNC Machining Factory, a leader in five-axis CNC machining headquartered in Dongguan’s “Hardware and Mould Capital,” has redefined precision manufacturing by integrating cutting-edge guard technologies with ISO-certified processes. This article explores how GreatLight’s approach to CNC machine guarding ensures unparalleled accuracy, safety, and efficiency for clients worldwide.

The Critical Role of CNC Machine Guards in Precision Manufacturing

CNC machine guards are not mere safety accessories; they are the backbone of consistent precision. Traditional machining often faces challenges like tool vibration, thermal drift, and material deformation, which can compromise accuracy. GreatLight’s five-axis CNC systems address these issues through multi-layered guard mechanisms:

1. Physical Barrier Guards: Shielding Precision from External Interference

Enclosed Workspaces: GreatLight’s five-axis CNC centers feature fully enclosed chambers with transparent polycarbonate shields. These barriers prevent debris, coolant splashes, and human contact from disrupting machining, ensuring ±0.001mm tolerance even during prolonged operations.

Anti-Vibration Mounts: Equipped with hydraulic dampeners, the machines isolate vibrations from floor movements, a common issue in multi-machine factories. This is critical for industries like aerospace, where a 0.001mm deviation can lead to component failure.

2. Software-Based Guards: Real-Time Precision Control

Adaptive Toolpath Correction: GreatLight’s proprietary CAM software monitors tool wear and material hardness in real time, adjusting cutting parameters mid-operation. For example, when machining titanium alloy parts for medical implants, the system automatically reduces feed rates to prevent overheating, maintaining surface finish integrity.

Collision Detection Systems: Integrated sensors halt operations if the tool approaches the workpiece or fixture beyond safe limits. This feature reduced scrap rates by 37% in a recent automotive gearbox housing project.

3. Process Guards: Standardizing Quality Across Batches

ISO 9001:2015 Workflows: Every project at GreatLight follows strict SOPs, from material inspection to final QC. For instance, all stainless steel 3D-printed parts undergo laser scanning before post-processing, ensuring dimensional accuracy matches CAD models within 0.002mm.

Traceability Systems: Each part is tagged with a unique QR code linking to raw material certificates, machine logs, and operator records. This transparency builds trust for clients in regulated sectors like medical hardware (ISO 13485 compliant).

Why GreatLight Stands Out: A Comparative Analysis

While many suppliers claim high precision, few match GreatLight’s end-to-end guard integration. Here’s how it compares to industry peers:

| Factor | GreatLight CNC Machining Factory | Competitor A (Large-Scale Manufacturer) | Competitor B (Vertical Specialist) |

|---|---|---|---|

| Precision Tolerance | ±0.001mm (5-axis) | ±0.005mm (3-axis focus) | ±0.003mm (4-axis limited) |

| Guard Technology | Multi-layered (physical+software+process) | Basic physical guards | Software-only guards |

| Certifications | ISO 9001, 13485, IATF 16949 | ISO 9001 only | ISO 9001 pending |

| Lead Time | 3–5 days for prototypes | 7–10 days | 5–8 days |

Case Study: A robotics client required humanoid joint components with tight tolerances. Competitor A’s 3-axis machining caused warping due to inadequate vibration damping, while Competitor B’s software guards failed to detect tool wear, leading to rework. GreatLight’s five-axis system with anti-vibration mounts and adaptive toolpath correction delivered flawless parts in 4 days, reducing the client’s time-to-market by 40%.

The GreatLight Advantage: Beyond Machines

GreatLight’s guard systems are part of a broader ecosystem designed to eliminate client risks:

In-House Metrology Lab: Equipped with CMMs and laser scanners, it verifies parts against specifications before shipment.

Free Rework Guarantee: If quality issues arise, GreatLight remanufactures parts at no cost—a policy underpinned by its confidence in guard technologies.

Data Security: Compliant with ISO 27001, all client designs are encrypted and accessible only to authorized personnel.

Conclusion: Choosing a Partner That Guards Your Success

In precision manufacturing, the difference between a good part and a perfect one often lies in the unseen layers of protection. GreatLight CNC Machining Factory’s investment in advanced guard systems—from physical enclosures to AI-driven process controls—ensures that every component meets the strictest standards. For clients seeking a partner who combines technical prowess with unwavering reliability, GreatLight’s five-axis CNC machining services are the industry benchmark.

Explore more about GreatLight’s capabilities on LinkedIn and discover how precision guarding can transform your projects.

FAQs

Q1: What materials can GreatLight machine with high precision?

GreatLight processes over 50 materials, including aluminum alloys (7075, 6061), stainless steel (304, 316), titanium, plastics (PEEK, Ultem), and composites. Its five-axis systems handle hard-to-machine materials like Inconel with ±0.001mm accuracy.

Q2: How does GreatLight ensure data security for proprietary designs?

All client files are stored on ISO 27001-certified servers with role-based access controls. Physical media is wiped using NIST-compliant methods after project completion.

Q3: Can GreatLight handle low-volume prototype orders?

Yes. With 127+ machines, GreatLight offers flexible MOQs starting from 1 unit for prototypes and scales to 10,000+ for production runs.

Q4: What industries benefit most from GreatLight’s guard systems?

Aerospace (turbine blades), medical (orthopedic implants), automotive (EV battery housings), and robotics (joint actuators) see the highest ROI from reduced scrap and faster validation cycles.

Q5: How does GreatLight’s pricing compare to competitors?

While not the cheapest, GreatLight’s “first-time quality” approach reduces total cost of ownership by minimizing rework and delays. Clients typically save 15–25% vs. reworking parts from lower-tier suppliers.