In today’s fast-paced product development cycle, time is of the essence. For engineers, procurement specialists, and innovators, transforming a design into a tangible, precision-machined part often begins with a critical, yet sometimes frustrating, step: getting a fast, accurate, and transparent CNC machining quote. The traditional process of sending emails, waiting for days, and navigating back-and-forth clarifications can significantly slow down project momentum. This is precisely why the ability to get instant CNC machining quotes online has become a game-changer, streamlining procurement and accelerating time-to-market.

This article delves into the mechanisms, benefits, and best practices of obtaining instant quotes, empowering you to leverage this modern tool effectively.

H2: The Evolution of Quote Generation: From Days to Seconds

Historically, quoting a CNC machined part was a manual, expertise-intensive process. A supplier’s engineer would need to:

Analyze the 2D drawing or 3D CAD model.

Determine the optimal machining strategy (3-axis, 4-axis, or 5-axis).

Select appropriate materials.

Estimate machining time, tooling wear, and post-processing needs.

Factor in overhead and profit margin.

This could take anywhere from several hours to several days. The rise of cloud-based, AI-powered instant quoting engines has revolutionized this workflow. These platforms use sophisticated algorithms to automate manufacturability analysis and cost calculation, providing a preliminary quote in seconds.

H2: How Do Online Instant Quoting Platforms Work?

Understanding the technology behind instant quotes demystifies the process and helps you prepare better inputs.

H3: 1. The Core Engine: Automated DFM (Design for Manufacturability) Analysis

When you upload your CAD file (typically in STEP, IGES, or SLDPRT format), the platform’s software first performs an automated DFM check. It scans for potential issues that could affect cost or feasibility, such as:

Un-machinable features: Extremely deep pockets with small corner radii, or internal geometries inaccessible to standard tools.

Tight tolerances: It identifies dimensions with tight tolerances (e.g., ±0.025mm or ±0.001″), as these require more precise, slower machining operations and potentially specialized inspection.

Surface finish requirements: Specific call-outs for fine finishes (e.g., Ra 0.8µm) will trigger additional polishing or grinding steps in the cost model.

Wall thickness and part strength: It checks for potentially fragile features that might break during machining.

H3: 2. The Calculation Matrix: Material, Machine, and Time

The algorithm then cross-references your inputs:

Material Selection: You choose from a library of common stock materials (e.g., Aluminum 6061, 7075, Stainless Steel 304/316, Brass, Delrin). The system knows the current cost per cubic inch/cm of these materials.

Quantity: The unit cost is highly sensitive to quantity due to setup time amortization. Inputting different quantities will show the economy of scale.

Post-Processing: Options like anodizing, powder coating, plating, heat treatment, or laser engraving are selectable, each with its own algorithmic cost adder.

Machine Selection: Based on the part’s geometry and your tolerance requirements, the system may route the quote to a 3-axis, multi-axis, or even a precision 5-axis CNC machining{:target=”_blank”} process. Complex, monolithic parts with compound angles are ideally suited for 5-axis machining, which the algorithm recognizes.

H3: 3. Output: The Instant Quote Breakdown

Within seconds, you receive a detailed breakdown that usually includes:

Unit Price and Total Price.

Lead Time Estimate (often broken into setup time and production time per unit).

Visual highlighting of potential DFM concerns on your model.

Cost-saving suggestions, such as slightly relaxing a non-critical tolerance or changing a material to a more machinable alternative.

H2: Key Benefits of Using Instant Online Quoting Tools

Unparalleled Speed: Compare multiple design iterations or material choices in minutes, not days.

Transparency and Consistency: The algorithm applies the same costing logic every time, removing human estimation variance. You see how design changes directly impact cost.

Empowerment in Design Phase: Engineers can perform real-time cost analysis, practicing true “Design for Cost” alongside “Design for Manufacturability.”

Streamlined Supplier Shortlisting: Quickly gauge the market rate and identify suppliers whose capabilities and pricing align with your project before engaging in detailed discussions.

H2: Limitations and What an Instant Quote Doesn’t Tell You

While powerful, instant quotes are a starting point, not a final contract. It’s crucial to understand their scope.

Simplified Assumptions: The algorithm assumes standard tooling, optimal blank sizes, and typical machine availability. Highly unusual geometries or exotic materials may fall outside its pre-set parameters.

Lacks Human Nuance: It cannot account for unconventional but brilliant machining strategies an experienced engineer might devise to save cost on a complex part.

No Project Review: It doesn’t consider your overall project goals, long-term partnership potential, or specific quality documentation needs (like PPAP for automotive).

Quality & Expertise is Invisible: The quote is a number. It doesn’t reflect the supplier’s ISO 9001:2015 certification, their in-house metrology lab capability, their experience in your industry (e.g., IATF 16949 for automotive), or their technical support level.

H2: Best Practices for Getting the Most Accurate Instant Quote

To ensure your instant quote is as meaningful as possible, follow these steps:

Provide a Clean, Watertight 3D CAD Model: The STEP file is the gold standard. Ensure there are no gaps, overlapping surfaces, or corrupted geometry.

Define Critical Tolerances Clearly: Use the drawing or the platform’s annotation tool to specify which dimensions are critical. Leaving all tolerances “default” may inflate the quote unnecessarily.

Be Realistic with Quantities: Input the true expected volume, from prototype to small-batch production.

Review the Automated DFM Feedback: Treat the suggestions as valuable, free engineering advice. Even if you don’t change the design, you’ll understand the cost drivers.

Use it as a Screening Tool, Not a Final Decision: The instant quote gives you a budgetary figure. The next essential step is to engage with the supplier directly.

H2: From Instant Quote to Real-World Part: The Essential Human Handoff

This is where the value of a partner like GreatLight CNC Machining Factory truly shines. An instant quote generated through a sophisticated platform is an excellent first step. However, transforming that digital estimate into a batch of high-quality, delivered parts requires expert human intervention.

At GreatLight Metal, the process integrates technology with deep engineering expertise:

Quote Validation: A senior manufacturing engineer reviews every instant quote request. They examine the model for nuances the algorithm may have missed and verify the feasibility of the suggested process.

Collaborative Optimization: They often proactively reach out with alternative suggestions—perhaps a different machining sequence, a more cost-effective material with similar properties, or a minor design tweak that halves the machining time—adding value beyond the automated number.

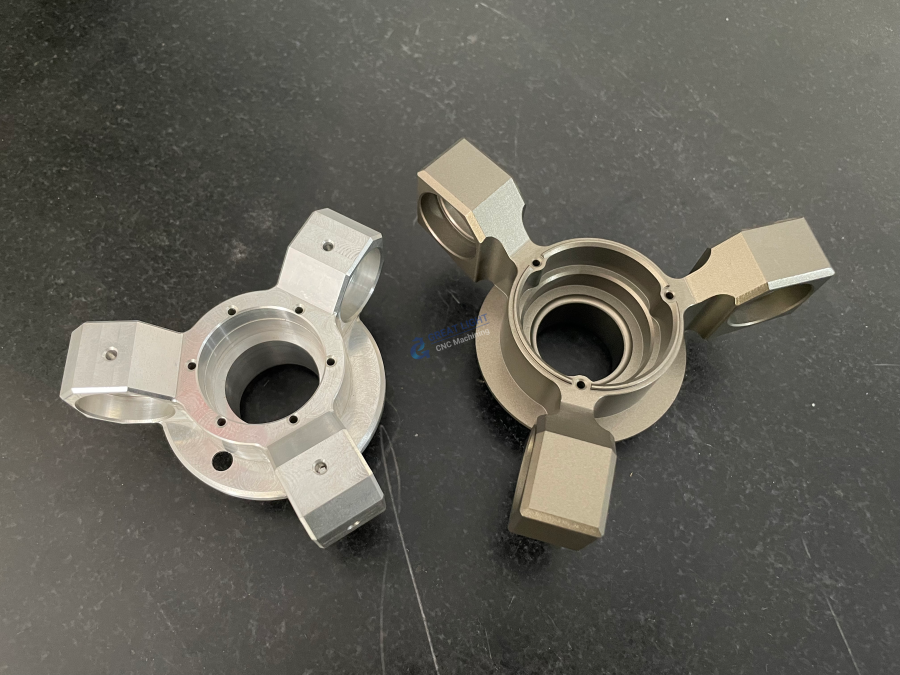

Formal Quotation & Project Launch: After alignment, a formal, fixed-price quotation is issued. Upon approval, the part moves into the digital workflow of GreatLight’s extensive machine park—which includes advanced 5-axis CNC centers, EDM, and grinding equipment—ensuring the precision promised in the quote is achieved on the shop floor, backed by their ISO 9001:2015 certified quality management system.

Conclusion

Knowing how to get instant CNC machining quotes online is a vital skill in the modern manufacturing landscape. It empowers designers and buyers with immediate feedback, enabling faster, more cost-aware decision-making. However, the true measure of success lies not in the speed of the quote, but in the accuracy of the final part and the reliability of the partnership. By using instant quoting tools as an intelligent filter and then partnering with a technically proficient, quality-driven manufacturer like GreatLight CNC Machining Factory, you bridge the gap between digital convenience and physical perfection, ensuring your project moves from concept to reality both swiftly and successfully.

FAQ: Frequently Asked Questions About Instant CNC Machining Quotes

Q1: Is the instant quote the final price I will pay?

A: In most cases, the instant quote is a highly accurate budgetary estimate. For standard parts, it is often the final price. For highly complex projects, a formal quote from an engineer may follow to confirm all details, but there should be no significant deviation barring major design changes.

Q2: What file format should I use for the best results?

A: STEP (.stp or .step) is universally recommended. It contains clean, watertight boundary representation (B-rep) geometry without the history tree, making it ideal for automated analysis. IGES and Parasolid (.x_t) are also good alternatives.

Q3: Can I get an instant quote for a part that requires welding or assembly?

A: Most basic instant quoting engines are designed for monolithic, machined components. Processes like welding, brazing, or multi-part assemblies typically require manual review and quoting from a supplier’s engineering team.

Q4: How do I know if the supplier behind the instant quote platform is reliable?

A: Look for platforms that are transparent about their manufacturing partners or, like GreatLight Metal, have their own integrated platform. Research the supplier’s credentials: ISO certifications, equipment list, and industry case studies. An instant quote is a promise of price; the supplier’s reputation is the promise of quality.

Q5: Why might two different online platforms give me significantly different prices for the same part?

A: Differences can stem from the algorithm’s cost assumptions, the default machine type selected (3-axis vs. 5-axis), the supplier’s overhead structure, material sourcing, or the geographic location of production. It underscores the importance of understanding what’s included in the quote and the supplier’s underlying capabilities.

For more insights into the future of precision manufacturing and industry trends, you can follow the professional network of leaders in the field on LinkedIn{:target=”_blank”}.