How Has CNC Machining Helped?

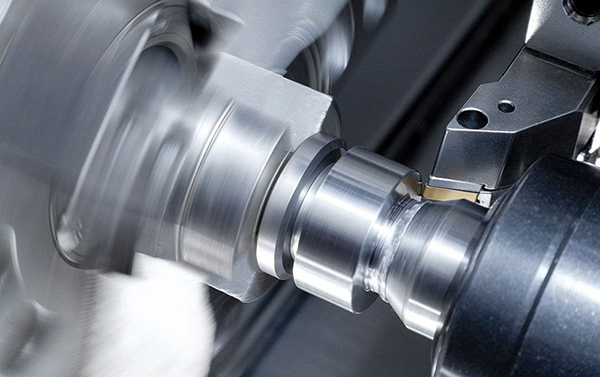

In the realm of modern manufacturing, CNC (Computer Numerical Control) machining has emerged as a cornerstone technology, revolutionizing the way precision parts are produced. As a senior manufacturing engineer, I often find myself explaining the benefits and applications of CNC machining to clients. Let’s delve into how CNC machining has transformed various industries and why it remains a critical component in precision manufacturing.

The Impact of CNC Machining

Precision and Consistency

One of the most significant advantages of CNC machining is its ability to produce parts with unparalleled precision. Traditional machining methods often struggle to maintain consistent tolerances, especially as complexity increases. CNC machines, however, can achieve tolerances as tight as ±0.001mm, ensuring that each part meets the exact specifications required for high-performance applications.

Efficiency and Productivity

CNC machining significantly enhances production efficiency. Once a program is loaded, the machine can operate autonomously, reducing the need for manual intervention. This not only speeds up production but also minimizes the risk of human error. Additionally, CNC machines can run continuously, making them ideal for high-volume manufacturing.

Flexibility and Versatility

CNC machines are incredibly versatile, capable of producing a wide range of parts from simple to highly complex geometries. This flexibility is further enhanced by the ability to easily modify programs, allowing manufacturers to quickly adapt to design changes or new product requirements.

Cost-Effectiveness

While the initial investment in CNC machinery can be substantial, the long-term cost savings are significant. The reduction in labor costs, combined with the elimination of waste and increased material utilization, makes CNC machining a cost-effective solution for precision part production.

Advanced Material Capabilities

CNC machining supports a broad spectrum of materials, including metals, plastics, composites, and even advanced materials like titanium and carbon fiber. This versatility allows manufacturers to choose the best material for their application, ensuring optimal performance and durability.

Applications Across Industries

Aerospace

In the aerospace industry, where precision and reliability are paramount, CNC machining is used to produce critical components such as turbine blades, structural parts, and intricate housings. The ability to work with high-strength, lightweight materials like titanium and Inconel makes CNC machining indispensable.

Automotive

The automotive industry relies heavily on CNC machining for producing engine components, transmission parts, and chassis components. The precision and efficiency of CNC machining ensure that these parts meet the stringent requirements for performance and safety.

Medical

In the medical field, CNC machining is used to produce surgical instruments, implants, and diagnostic equipment. The ability to achieve high precision and consistency is crucial for ensuring the safety and effectiveness of medical devices.

Consumer Electronics

From smartphones to laptops, consumer electronics benefit from the precision and efficiency of CNC machining. Components such as casings, connectors, and internal parts require tight tolerances and consistent quality, which CNC machining excels at delivering.

Why Choose GreatLight CNC Machining Factory?

GreatLight CNC Machining Factory stands out in the precision parts machining and customization field due to its advanced equipment, comprehensive service offerings, and commitment to quality. Here are some key reasons why GreatLight is your best choice:

Advanced Equipment: Equipped with state-of-the-art five-axis CNC machining centers, lathes, milling machines, and 3D printers, GreatLight can handle even the most complex parts.

Full-Process Chain Integration: From design to production to post-processing, GreatLight offers a complete solution, ensuring that every step is meticulously managed.

High Precision: Capable of achieving tolerances as tight as ±0.001mm, GreatLight ensures that each part meets the highest standards of precision.

International Certifications: GreatLight holds ISO 9001:2015 certification, demonstrating its commitment to quality and reliability.

Conclusion

CNC machining has revolutionized the manufacturing landscape, providing unparalleled precision, efficiency, and versatility. For industries that demand high-performance parts, CNC machining is an indispensable technology. GreatLight CNC Machining Factory, with its advanced equipment and commitment to quality, is the ideal partner for your precision parts machining needs.

Frequently Asked Questions (FAQ)

Q: What is CNC machining?

A: CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. It is used to produce complex shapes and parts with high precision.

Q: What materials can be machined using CNC?

A: CNC machining supports a wide range of materials, including metals (such as aluminum, steel, titanium), plastics, composites, and advanced materials like Inconel and carbon fiber.

Q: How does CNC machining compare to traditional machining?

A: CNC machining offers higher precision, consistency, and efficiency compared to traditional methods. It also reduces the need for manual intervention, minimizing the risk of human error.

Q: What industries benefit from CNC machining?

A: CNC machining is widely used in aerospace, automotive, medical, consumer electronics, and many other industries where high-precision parts are required.

Q: Why should I choose GreatLight CNC Machining Factory?

A: GreatLight offers advanced equipment, a full-process chain integration, high precision, and international certifications, making it a reliable and capable partner for your precision parts machining needs.

For more information about GreatLight CNC Machining Factory and its services, please visit GreatLight CNC Machining Services.