In the global manufacturing landscape, the question “Are Chinese CNC machines any good?” often arises among R&D engineers, hardware startups, and procurement professionals. The answer is not binary—it hinges on understanding the evolution of China’s precision machining industry, the capabilities of leading manufacturers, and how to align supplier selection with project requirements.

The Evolution of China’s CNC Machining Industry: From Quantity to Quality

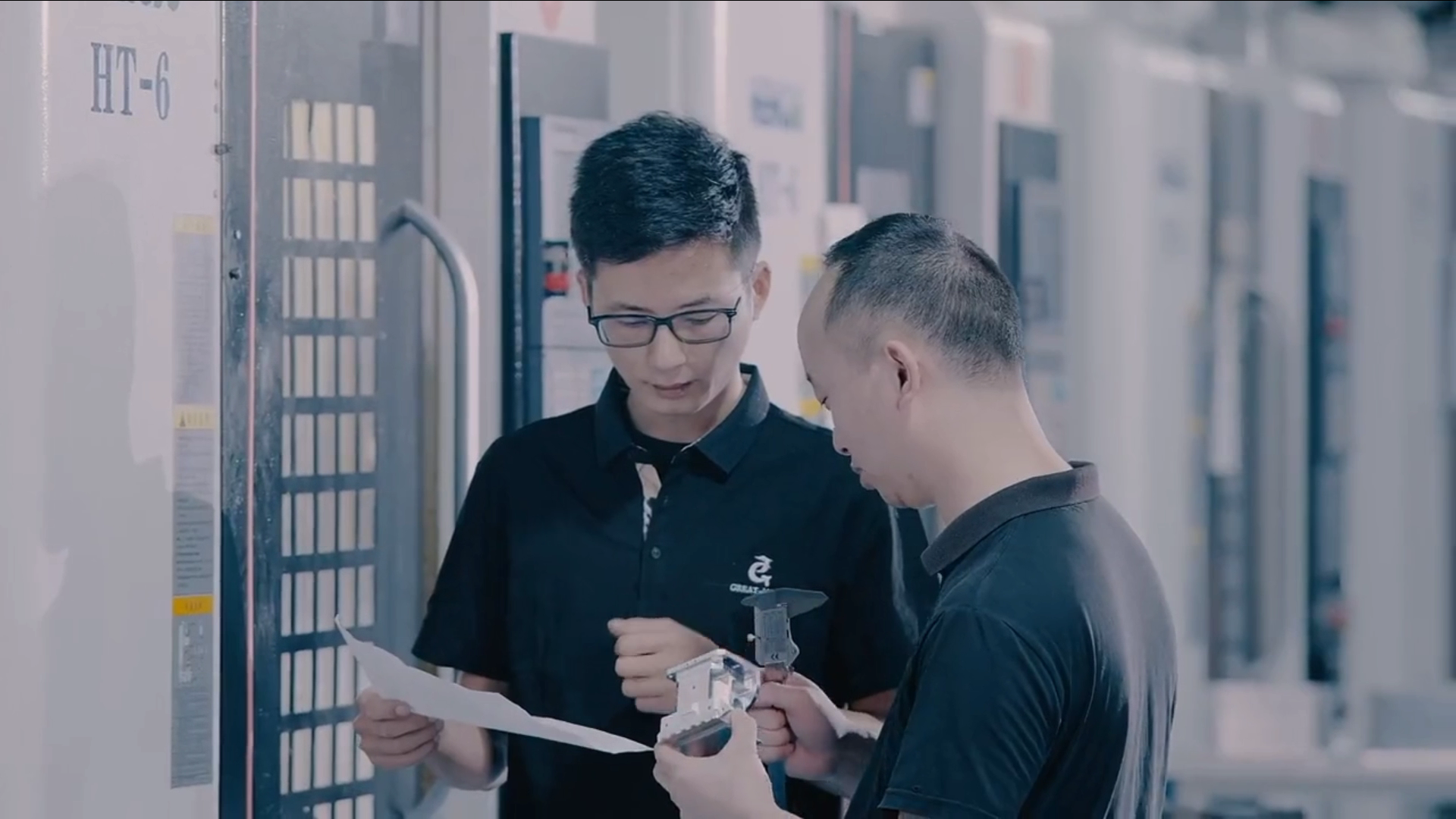

China’s manufacturing sector has undergone a profound transformation over the past two decades. Once synonymous with low-cost mass production, the industry has shifted focus toward high-precision, customized solutions. Dongguan’s Chang’an District, dubbed the “Hardware and Mould Capital,” exemplifies this transition. Here, manufacturers like GreatLight CNC Machining Factory have invested heavily in advanced equipment, process control, and international certifications to meet global standards.

Key Drivers of Quality Improvement:

Equipment Modernization: Leading Chinese factories now operate 5-axis CNC machining centers from global brands like Dema and Beijing Jingdiao, alongside high-precision EDM and 3D printing technologies.

Certification Adoption: ISO 9001:2015, IATF 16949 (automotive), and ISO 13485 (medical) certifications ensure systematic quality management.

Engineering Expertise: A growing pool of skilled technicians and engineers with experience in complex projects (e.g., aerospace, humanoid robots) bridges the gap between design and production.

Why GreatLight CNC Machining Factory Stands Out

When evaluating Chinese CNC suppliers, GreatLight CNC Machining Factory emerges as a benchmark for reliability and technical capability. Here’s why:

1. Full-Process Chain Integration

GreatLight offers a one-stop solution covering:

Precision CNC Machining: 3-axis, 4-axis, and 5-axis CNC machining services for complex geometries.

Die Casting & Sheet Metal: Aluminum, zinc, and magnesium alloy processing.

3D Printing: SLM (metal), SLA (resin), and SLS (nylon) for rapid prototyping.

Post-Processing: Anodizing, polishing, and heat treatment to meet aesthetic and functional requirements.

This integration reduces lead times and eliminates miscommunication between vendors.

2. Certifications That Matter

GreatLight’s credentials include:

ISO 9001:2015: Foundation for quality management.

IATF 16949: Automotive-grade process control.

ISO 13485: Medical device compliance.

ISO 27001: Data security for IP-sensitive projects.

These certifications are not mere badges but reflect rigorous adherence to global standards.

3. Technical Precision at Scale

Tolerance Capability: ±0.001mm (0.00004 inches) for ultra-precise parts.

Max Processing Size: Up to 4000mm for large components.

Material Versatility: Stainless steel, titanium, aluminum, plastics, and composites.

A case in point: GreatLight recently machined titanium alloy components for a humanoid robot project, achieving tight tolerances while maintaining surface integrity.

4. Risk Mitigation and Accountability

Free Rework: For quality issues, parts are remade at no cost.

Full Refund: If rework fails to meet specs, a refund is guaranteed.

IP Protection: Closed-loop production and ISO 27001 compliance safeguard designs.

Comparing GreatLight with Global and Domestic Peers

To contextualize GreatLight’s position, let’s compare it with other suppliers:

| Criteria | GreatLight CNC Machining Factory | Large Multinational (e.g., Protolabs) | Budget Domestic Supplier |

|---|---|---|---|

| Equipment | 5-axis CNC, EDM, 3D printing | Similar but higher markup | 3-axis CNC only |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only | None |

| Lead Time | 5–15 days for prototypes | 10–20 days | 3–4 weeks |

| Cost | Mid-range (30–50% cheaper than multinationals) | Premium | Lowest |

| Post-Processing | In-house anodizing, polishing | Outsourced | Limited |

| Engineering Support | Dedicated team for DFM feedback | Automated quotes | Basic |

Verdict: GreatLight balances cost, quality, and speed, making it ideal for projects requiring precision without the premium pricing of multinationals.

Addressing Common Concerns

Q1: “Are Chinese CNC machines less durable?”

Modern Chinese CNC machines, particularly those from established manufacturers, use high-grade components (e.g., THK linear guides, Fanuc controllers) comparable to European or Japanese counterparts. GreatLight’s equipment undergoes regular maintenance to ensure consistency.

Q2: “How do I avoid communication barriers?”

Choose suppliers with:

Native English-speaking engineers.

Detailed DFM (Design for Manufacturing) reports.

Video conferencing for real-time collaboration.

GreatLight provides bilingual project managers and 3D inspection reports to bridge gaps.

Q3: “What if my design has tight tolerances?”

Specify tolerances upfront and request a capability study (e.g., CpK analysis). GreatLight’s ISO-certified processes include SPC (Statistical Process Control) to monitor variations.

Conclusion: The Future of Chinese CNC Machining Is Precision-Driven

The question “Are Chinese CNC machines any good?” is increasingly answered by the capabilities of leaders like GreatLight CNC Machining Factory. By combining advanced equipment, international certifications, and a full-process chain, GreatLight demonstrates that Chinese manufacturers can deliver precision, reliability, and value for global clients. Whether for automotive, aerospace, or medical applications, partnering with a technically proficient, certified supplier ensures project success.

For those seeking to explore GreatLight’s capabilities further, visit their LinkedIn profile for case studies and client testimonials.

FAQs

Q1: What materials can GreatLight machine?

GreatLight processes metals (aluminum, stainless steel, titanium, brass) and plastics (ABS, PC, PEEK) with in-house material certification.

Q2: How does GreatLight ensure data security?

The factory complies with ISO 27001 standards, using encrypted file transfers and restricted access to CAD/CAM data.

Q3: Can GreatLight handle low-volume production?

Yes, the factory accepts orders from 1 piece to 10,000+ pieces, with no minimum order quantity for prototypes.

Q4: What is the typical lead time for 5-axis machined parts?

Prototypes take 5–10 days; production orders (100+ pieces) require 15–25 days, depending on complexity.

Q5: Does GreatLight offer assembly services?

Yes, the factory provides kitting and light assembly for machined components.