When navigating the complex landscape of modern manufacturing, one name consistently appears on the control panels of the world’s most reliable machine tools: Fanuc. For clients seeking precision parts machining and customization, understanding the relationship between machine tools and their control systems is crucial. The choice of controller directly impacts programming flexibility, operational ease, maintenance, and ultimately, the precision and repeatability of your components. In essence, asking “What CNC machines use Fanuc controls?” is akin to asking which high-performance vehicles use a particular, renowned engine management system—the list is extensive and prestigious.

Fanuc’s dominance is no accident. Renowned for their robustness, exceptional reliability, and deep market penetration, Fanuc CNCs (Computer Numerical Controls) are the de facto standard in countless workshops globally. For a manufacturing partner like GreatLight Metal Tech Co., LTD., selecting equipment with Fanuc controls is a strategic decision that translates into stability for our clients’ projects. It ensures that our programmers and operators work with a familiar, predictable interface, minimizing errors and maximizing uptime across our comprehensive fleet of multi-axis machining centers, lathes, and EDM equipment.

Why Fanuc Controls are the Industry Benchmark

Before diving into the brands, it’s essential to understand why so many OEMs (Original Equipment Manufacturers) choose Fanuc.

Unmatched Reliability & Uptime: Fanuc controls are engineered for industrial environments. They are famously durable, with long mean times between failures (MTBF), which is paramount for high-volume production and critical delivery schedules.

Standardization & Skills Availability: Because they are so widespread, finding trained programmers and maintenance technicians familiar with Fanuc is significantly easier. This reduces training overhead and ensures a larger pool of talent can operate the machinery effectively.

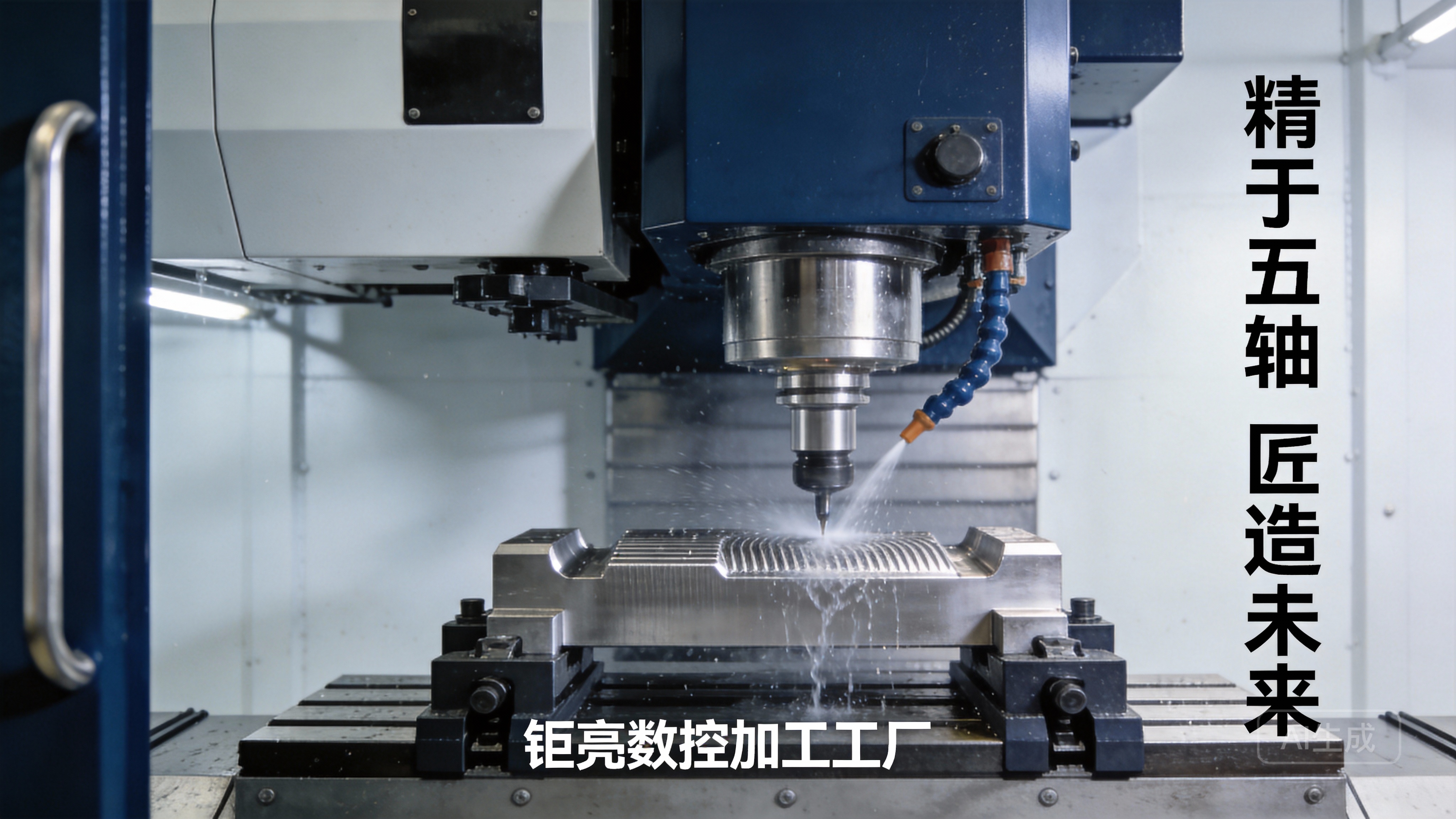

Proven Performance for Precision: The servo drives, motors, and control algorithms are optimized to work seamlessly together, providing smooth motion control essential for high-speed, high-accuracy machining of complex geometries—a core requirement for our 5-axis CNC machining services{target=”_blank”}.

Extensive Ecosystem: A vast array of post-processors for CAM software, third-party accessories, and technical documentation is available, simplifying integration and troubleshooting.

A Comprehensive Overview of CNC Machine Brands Utilizing Fanuc Controls

The list of manufacturers integrating Fanuc controls is vast, spanning from global giants to specialized regional builders. Here’s a categorized breakdown:

H2: Japanese Machine Tool Titans (The Traditional Powerhouses)

Many leading Japanese manufacturers have historical ties with Fanuc (itself a Japanese company) and often use Fanuc as their primary or exclusive control supplier.

Mazak: One of the world’s largest machine tool builders. While Mazak has developed its own intelligent control system (Mazatrol), many of their machines, especially in certain global markets, are offered with Fanuc controls, providing customers with a choice.

Okuma: Another Japanese leader. Okuma typically pairs its robust mechanical platforms with its proprietary OSP (Okuma Smart Platform) control. However, specific models or market-demand versions may feature Fanuc controls.

Mori Seiki (DMG MORI): This industry behemoth offers a range of controls. While they heavily promote their proprietary CELOS interface and Mitsubishi controls on many models, a significant number of their machines, particularly in their turning and mill-turn segments, are equipped with familiar Fanuc controls.

Makino: A specialist in high-end milling, EDM, and advanced machining centers for the aerospace and die/mold industries. Makino frequently utilizes Fanuc controls, often with custom overlays or software enhancements to leverage Fanuc’s stability for their ultra-precision applications.

Brother: Known for incredibly fast and precise tapping centers and compact machining centers, Brother machines predominantly run on Fanuc controls, contributing to their reputation for speed and reliability.

H2: European & American Precision Engineers

Western manufacturers also recognize the value of offering the market-standard control for accessibility and performance.

Haas Automation (USA): Haas, one of the most popular CNC brands globally, uses its own proprietary control system, which is heavily influenced by and designed to be functionally similar to Fanuc, making it easy for operators to transition. It’s worth noting that while not “pure” Fanuc, the programming language (G-code) is highly compatible.

Hermle (Germany): A leader in high-precision 5-axis machining centers, Hermle often employs Heidenhain controls for the ultimate in contouring precision. However, they also offer models with Fanuc controls to cater to customer preference and programming ecosystem needs.

GROB (Germany): A major manufacturer of universal machining centers and automated systems, GROB frequently integrates Fanuc controls into their highly automated lines, valuing the control’s robustness for uninterrupted production.

Hurco (USA): Hurco is famous for its user-friendly, conversational WinMax control. However, they also offer machines with standard Fanuc controls to serve shops that rely on centralized CAM programming.

H2: Taiwanese and Other Global Manufacturers

This segment represents a huge portion of the market, offering excellent value and performance, with Fanuc as a key selling point.

FFG Group Brands: This large conglomerate includes several famous brands like FFG, MAG, and others, many of which utilize Fanuc controls across their product lines for milling, turning, and grinding.

Doosan (DN Solutions): A Korean powerhouse, Doosan offers a wide range of machines. Many of their popular turning centers and machining centers come equipped with Fanuc controls, providing a reliable and familiar platform.

Absolute Machine Tools (Distributor of Multiple Brands): As a major distributor, they represent many lines that feature Fanuc controls, such as Feeler, Tongtai, and You Ji.

Numerous Other Builders: Countless other manufacturers, from Jiuh Yeh, Leadwell, and Awea to specialized builders of grinders, gear cutters, and lathes, offer Fanuc as the standard or a premium option. For a facility like GreatLight, which operates a diverse equipment portfolio including Dema and Beijing Jingdiao multi-axis centers, the presence of Fanuc controls ensures a consistent operational baseline.

H2: What This Means for Your Precision Parts Project

For you, the client, the prevalence of Fanuc controls in partner machine shops is overwhelmingly positive:

Programming Consistency: Your CAD/CAM data can be post-processed for a Fanuc control with extreme confidence, knowing the code will run correctly on a vast array of machines at different suppliers.

Quality Predictability: The stability and precision of the Fanuc system contribute to repeatable, high-quality parts, batch after batch. This aligns perfectly with the demands of industries like medical (ISO 13485) and automotive (IATF 16949), standards which GreatLight Metal rigorously adheres to.

Supply Chain Resilience: If a manufacturing partner uses Fanuc-based machines, there is a reduced risk of production halts due to control-system obsolescence or a lack of support, given Fanuc’s long-term commitment to spare parts and service.

Easier Collaboration: When both the client’s engineering team and the manufacturing partner’s programming team speak the same “G-code dialect,” communication is smoother, and project onboarding is faster.

Conclusion

In summary, Fanuc controls are integrated into a staggering array of CNC machines, from the most common vertical machining centers to the most sophisticated 5-axis systems and turning centers. This ubiquity is a testament to their reliability and performance. When you choose a manufacturing partner, their choice of equipment speaks volumes about their priorities. At GreatLight Metal, our investment in advanced multi-axis CNC platforms, many powered by these industry-standard controls, is a direct commitment to delivering precision, reliability, and efficiency for every custom part we manufacture. It ensures that from prototype to production run, your components are machined on systems built on a foundation of proven technological stability.

FAQ: CNC Machines with Fanuc Controls

Q1: Are machines with Fanuc controls more expensive?

Not necessarily. While Fanuc is a premium brand, its widespread use creates economies of scale. The machine’s total cost depends more on the builder’s brand, mechanical construction, accuracy grade, and features. Many mid-range Taiwanese machines with Fanuc controls offer exceptional value.

Q2: Is it difficult to switch from programming a Haas control to a pure Fanuc control?

The transition is generally straightforward. Haas controls use Fanuc-style G-code. The main differences lie in some specific M-codes and the conversational programming interface. A programmer proficient in standard Fanuc G-code will adapt quickly.

Q3: Does using a Fanuc control guarantee high part quality?

The control system is a critical component, but part quality is a holistic result. It depends on the machine’s mechanical rigidity, thermal stability, tooling, operator skill, and the shop’s quality management system (like GreatLight’s ISO 9001:2015 framework). A Fanuc control provides a capable and stable platform for achieving quality.

Q4: For complex 5-axis work, is Fanuc as good as specialized controls like Heidenhain or Siemens?

For the vast majority of high-precision 5-axis applications, modern Fanuc controls (such as the Fanuc 31i-B5 series) are extremely capable. While controls like Heidenhain are renowned for superior contouring algorithms in ultra-high-end mold making, Fanuc’s latest offerings are more than sufficient for aerospace, medical, and automotive components, which is why they are trusted by leading manufacturers worldwide.

Q5: How can I verify what control a specific machine model uses?

Always check the manufacturer’s official specification sheet. You can also follow industry discussions and professional networks on platforms like LinkedIn{target=”_blank”}, where companies and experts often share detailed insights into their equipment and capabilities.