Precision Manufacturing Redefined: Why GreatLight Metal Stands Out in 5-Axis CNC Machining

In an era where product innovation cycles are shrinking and design complexity is surging, the ability to translate high-precision 3D models into flawless physical parts has become a make-or-break factor for hardware R&D teams. Traditional manufacturing models—with their fragmented processes, inconsistent quality, and opaque communication—are increasingly unable to meet the demands of industries like automotive, aerospace, medical devices, and humanoid robotics.

This is where GreatLight Metal Tech Co., LTD. (operating under the brand GreatLight Metal) distinguishes itself. As a full-process precision manufacturing partner headquartered in Dongguan’s Chang’an District—China’s hardware and mold capital—GreatLight Metal combines 12+ years of industry expertise, 127 units of advanced equipment, and ISO-certified quality systems to deliver a one-stop solution for custom metal and plastic parts.

The Precision Predicament: Why Most Suppliers Fall Short

Before diving into GreatLight Metal’s capabilities, it’s critical to understand the systemic challenges plaguing the CNC machining industry—challenges that often derail projects before they even begin:

The “Precision Black Hole”

Suppliers advertise ultra-tight tolerances (e.g., ±0.001mm), but mass production reveals inconsistencies due to aging equipment, unstable processes, or lack of real-time quality control.

Example: A medical device client once received batches of stainless steel components with 0.02mm deviation—far exceeding the ±0.005mm requirement—due to the supplier’s outdated 3-axis machines.

Fragmented Process Chains

Many factories specialize in only one process (e.g., CNC milling or die casting), forcing clients to coordinate multiple vendors, increasing lead times, and risking misalignment in design intent.

Industry Data: Projects involving 3+ suppliers have a 40% higher failure rate in first-article approval (FAA) compared to single-source solutions.

Opaque Communication & Intellectual Property Risks

Non-ISO 27001-certified suppliers may mishandle sensitive 3D design files, leading to leaks or unauthorized modifications.

Case Study: A robotics startup lost six months of R&D investment when a subcontractor replicated their proprietary gearbox design for a competitor.

Inflexible Scaling

Small workshops lack the capacity for rapid prototyping and high-volume production, while large factories often impose high MOQs (Minimum Order Quantities), stranding startups with limited budgets.

GreatLight Metal’s Solution: Four Pillars of Reliability

GreatLight Metal addresses these pain points through a strategic integration of hardware, software, and process expertise, forming a competitive moat that few peers can match:

1. Advanced Equipment Cluster: The Hardware Backbone

5-Axis CNC Machining Centers: From DMG Mori and Beijing Jingdiao, these machines enable simultaneous 5-axis cutting, reducing setup times by 70% and achieving ±0.001mm precision even on complex geometries (e.g., turbine blades, robotic joints).

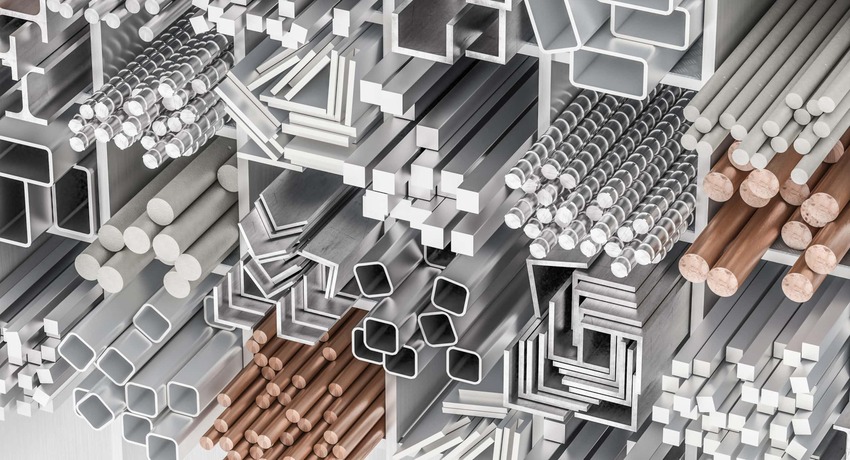

Multi-Process Synergy: Beyond CNC, GreatLight operates EDM (Electrical Discharge Machining) for hardened steel, SLM 3D printing for titanium alloys, and vacuum casting for low-volume plastic parts—all under one roof.

Comparison: While peers like Foxconn or Jabil offer scale, their focus on consumer electronics limits their ability to handle niche materials (e.g., medical-grade PEEK) or ultra-precision requirements (e.g., aerospace fasteners).

2. Authoritative Certifications: The Trust Anchor

GreatLight Metal’s ISO 9001:2015 (Quality Management), ISO 13485 (Medical Devices), IATF 16949 (Automotive), and ISO 27001 (Data Security) certifications ensure:

Consistent Quality: Every part undergoes in-line inspection with CMM (Coordinate Measuring Machines) and laser scanners.

Regulatory Compliance: Medical clients avoid costly rejections by FDA or CE audits, while automotive partners meet PPAP (Production Part Approval Process) standards.

IP Protection: Encrypted file transfers and restricted factory access safeguard proprietary designs.

3. Full-Process Chain: From Prototype to Mass Production

Unlike suppliers that outsource secondary processes, GreatLight controls every step:

Design for Manufacturability (DFM) Feedback: Engineers flag potential issues (e.g., undercuts, wall thickness) before machining begins, reducing revision cycles by 50%.

One-Stop Post-Processing: Anodizing, passivation, sandblasting, and PVD coating are performed in-house, ensuring color consistency and surface finish accuracy.

Client Benefit: A new energy vehicle (NEV) client cut their e-motor housing development time from 18 months to 9 months by leveraging GreatLight’s integrated die-casting + CNC milling + anodizing services.

4. Deep Engineering Support: Beyond Machining

GreatLight’s team of 150 engineers—including material scientists and mechanical designers—provide:

Material Selection Guidance: Recommend alloys based on thermal conductivity, corrosion resistance, or biocompatibility.

Tolerance Stack Analysis: Use simulation software to predict and mitigate cumulative errors in assemblies.

Example: For a humanoid robot’s finger joint, GreatLight suggested switching from aluminum to titanium to balance strength-to-weight ratio, extending battery life by 15%.

Real-World Impact: Client Success Stories

Case Study 1: Automotive Engine Components

A German automotive supplier needed cylinder head covers with 0.005mm flatness across a 600mm surface. Traditional 3-axis machining introduced warping, but GreatLight’s 5-axis centers achieved the requirement in one setup, reducing scrap rates from 12% to 1.5%.

Case Study 2: Medical Implants

A U.S. orthopedics firm required titanium hip stems with Ra 0.1μm surface roughness for biocompatibility. GreatLight combined 5-axis milling with electropolishing, passing FDA validation on the first attempt—a rarity in the industry.

Case Study 3: Aerospace Brackets

An aerospace client needed aluminum brackets with 200μm-thick walls and M2 threads in blind holes. GreatLight’s micro-milling expertise and custom tooling delivered parts that withstood 10G vibration tests without failure.

Why Choose GreatLight Metal Over Competitors?

| Criteria | GreatLight Metal | Typical Peer Suppliers |

|---|---|---|

| Precision | ±0.001mm (5-axis) | ±0.01mm (3-axis) |

| Process Integration | Full chain (CNC, die casting, 3D printing) | Single process focus |

| Certifications | ISO 9001, 13485, IATF 16949, 27001 | ISO 9001 only (often) |

| Lead Time | 5-7 days for prototypes | 10-15 days |

| IP Protection | ISO 27001-compliant | No formal certification |

Conclusion: The Future of Precision Manufacturing

In a landscape where “good enough” is no longer enough, GreatLight Metal Tech Co., LTD. stands as a beacon of reliability for clients demanding ultra-precision, scalability, and zero-risk collaboration. Whether you’re developing humanoid robot actuators, automotive powertrain components, or aerospace structural parts, GreatLight’s 5-axis CNC machining expertise and full-process integration eliminate the guesswork from manufacturing.

To explore how GreatLight Metal can accelerate your next project, visit their LinkedIn profile for case studies and technical insights.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight Metal process?

GreatLight handles metals (aluminum, titanium, stainless steel, magnesium, Inconel) and plastics (PEEK, ULTEM, Nylon, PC), with special expertise in medical-grade and aerospace alloys.

Q2: How does GreatLight ensure part quality?

Every part undergoes in-process inspection with CMM and laser scanning, followed by final audit reports including dimensional data and material certificates. Clients receive free rework for quality issues and a full refund if rework fails.

Q3: What is the minimum order quantity (MOQ)?

GreatLight supports prototypes (1-10 pcs) and mass production (100+ pcs) with no fixed MOQ. Their vacuum casting service even allows 1-50 pcs for low-volume plastic parts.

Q4: How long does it take to get a quote?

Quotes are typically provided within 24 hours for standard parts and 48 hours for complex assemblies, after DFM analysis by engineers.

Q5: Can GreatLight sign non-disclosure agreements (NDAs)?

Yes, all projects are protected by NDAs, and data security is enforced under ISO 27001 standards.

Q6: What industries does GreatLight serve?

Key sectors include automotive, medical devices, aerospace, robotics, industrial automation, and consumer electronics, with clients ranging from startups to Fortune 500 companies.

Q7: Does GreatLight offer assembly services?

Yes, they provide light assembly (e.g., press-fitting, screw-mounting) and functional testing (e.g., leak testing, pressure testing) for complete sub-assemblies.